When it comes to fabricating parts from plexiglass (also known as acrylic), a common and critical question arises: what’s best for cut plexiglass, laser or CNC machine? The answer is not a simple one-size-fits-all, as both laser cutting and CNC machining are excellent processes with distinct strengths. The “best” choice hinges entirely on your project’s specific requirements for precision, edge quality, part geometry, thickness, and volume. As a precision manufacturing engineer with extensive experience processing polymers and composites, I’ll provide a detailed, objective comparison to guide your decision-making.

Understanding the Core Technologies

First, let’s clarify how each technology interacts with plexiglass.

Laser Cutting utilizes a focused, high-power beam of light (typically CO2) to melt, burn, or vaporize the material along a programmed path. It is a non-contact, thermal process.

CNC Machining is a subtractive manufacturing process where a computer-controlled rotary cutting tool (end mill, drill, etc.) physically removes material to shape the part. It is a mechanical, contact-based process.

Head-to-Head Comparison: Laser Cutting vs. CNC Machining for Plexiglass

1. Edge Quality and Finish

This is one of the most significant differentiators.

Laser Cutting: Produces a characteristically smooth, polished, and flame-polished edge on cut edges. This is a major advantage for applications where aesthetics are paramount, such as displays, signage, or lenses. The heat of the laser essentially seals the cut edge. However, on thicker materials, slight tapering or a faint “waviness” can sometimes occur.

CNC Machining: Produces a machined edge that will have tool marks. While a skilled machinist using sharp tools and proper feeds/speeds can achieve a very clean edge, it will not have the innate gloss of a laser-cut edge. However, CNC milling allows for additional edge finishing operations in the same setup, such as chamfering, rounding (filleting), or creating complex edge profiles that a laser cannot achieve.

2. Precision and Tolerance

Laser Cutting: Excels at 2D profiling with extremely high accuracy and repeatability, often holding tolerances within ±0.1mm or better for intricate details and fine features. Kerf (the width of the cut) is consistent and very narrow.

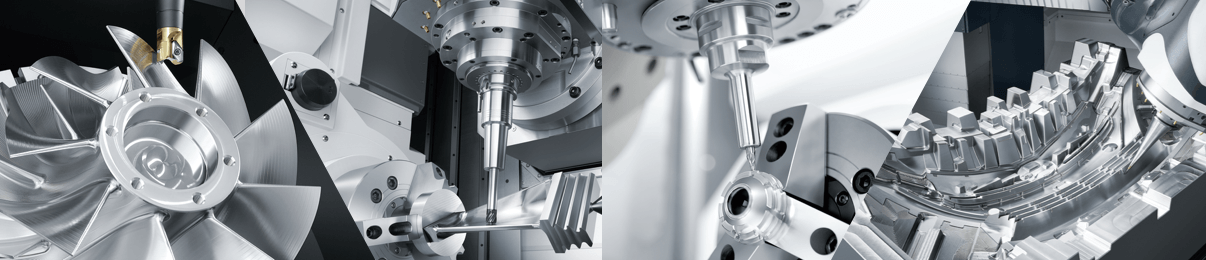

CNC Machining: Offers superior 3D geometric capability and can generally achieve tighter overall tolerances, down to ±0.025mm or less for critical dimensions. It is unmatched for creating complex 3D contours, pockets, steps, and true orthogonal holes with precise internal threads. The precision of a precision 5-axis CNC machining service is particularly valuable for functional prototypes or mechanical components requiring exacting fits.

3. Material Thickness and Capability

Laser Cutting: Best suited for thin to medium sheet stock. While lasers can cut thicker plexiglass, the edge quality often degrades, and the process becomes slower. There’s also a higher risk of thermal stress, internal cracking (crazing), or excessive melting on very thick sections.

CNC Machining: Handles a much wider range of thicknesses and solid blocks with consistent quality. Whether it’s a 1mm sheet or a 100mm thick block, CNC can machine it effectively without thermal damage concerns. It is the only option for machining parts from solid acrylic rod or slab.

4. Complexity of Design

Laser Cutting: Ideal for complex 2D outlines, intricate patterns, and delicate features. Changes to a design are as simple as updating the vector file. It is the go-to for flat parts with decorative cut-outs.

CNC Machining: The definitive solution for complex 3D parts. It can machine undercuts, complex curved surfaces, deep cavities, and multi-sided features in a single setup on a 5-axis machine. If your part isn’t flat, CNC is typically necessary.

5. Speed and Throughput

Laser Cutting: Generally faster for 2D profiling, especially for multiple identical parts nested on a single sheet. The non-contact nature allows for rapid movement between cuts.

CNC Machining: Can be slower for simple 2D shapes but provides unmatched flexibility. For complex 3D shapes, it is the only viable fast option. Speed is also highly dependent on the sophistication of the equipment.

6. Cost Considerations

Laser Cutting: Often has a lower setup cost and faster setup time, making it highly economical for short runs, prototyping, and flat parts. Material is typically used in sheet form.

CNC Machining: May have a higher initial setup cost (programming, fixturing) but becomes very cost-effective for complex parts, thicker materials, and medium to higher volumes where its multi-operation capability reduces overall part handling.

Conclusion: Making the Informed Choice

So, what’s best for cut plexiglass, laser or CNC machine? The decision matrix boils down to your part’s primary characteristics:

Choose LASER CUTTING if: Your part is primarily 2D, made from sheet stock (typically <20mm thick), requires a flawless polished edge for aesthetic reasons, involves intricate interior cutouts, and is needed in low to medium volumes with quick turnaround.

Choose CNC MACHINING if: Your part is a 3D component with depth, contours, or complex geometry; is made from thick solid blocks; requires ultra-tight tolerances and precise mechanical features (like threaded holes or precise bearing fits); or needs specific edge treatments beyond a simple cut.

At GreatLight CNC Machining Factory, we possess both advanced CO2 laser cutting systems and a full battery of multi-axis CNC machining centers. This integrated capability allows us to provide truly objective consultation. We often recommend a hybrid approach: using laser cutting for initial flat prototypes or decorative panels, and transitioning to precision CNC machining for the final functional 3D components that demand structural integrity and dimensional accuracy. Our expertise lies in selecting the optimal—and most cost-effective—path to bring your plexiglass design to life with the highest quality, whether through the focused energy of a laser or the mechanical precision of a CNC toolpath.

Frequently Asked Questions (FAQ)

Q1: Can laser cutting cause melting or damage to plexiglass?

A: Yes, laser cutting is a thermal process. If parameters (power, speed, focus) are not optimized, it can cause excessive melting, bubbling, or internal stress marks (crazing). A reputable manufacturer with experience in polymers will have perfected these settings to produce clean cuts.

Q2: Which process is better for very clear, optical-grade acrylic?

A: For the clearest edges with minimal visual distortion, high-quality laser cutting often provides a superior finish as it polishes the edge during cutting. However, for optical components requiring precise spherical or aspherical surfaces, CNC machining followed by meticulous polishing is the required method.

Q3: Is CNC machining more wasteful than laser cutting?

A: Both are subtractive processes. Laser cutting can be more efficient for nesting 2D parts from a sheet. CNC machining from a solid block generates more chips, but for complex 3D parts, it’s the only viable method. Waste is managed through optimized programming and block sizing.

Q4: Can you achieve a polished edge with CNC machining?

A: A machined edge can be polished in a secondary post-processing step (flame polishing, buffing, or diamond polishing), but this adds time and cost. The inherent edge from a properly tuned laser cutter is naturally polished.

Q5: For a project involving both flat panels and complex brackets from plexiglass, should I use two different suppliers?

A: Not necessarily. Partnering with a full-service manufacturer like GreatLight that offers both technologies provides significant advantages: unified quality control, streamlined communication, potential cost synergies, and a single point of accountability for your entire project, from flat precision 5-axis CNC machining for brackets. Learn more about our capabilities on our professional network at GreatLight on LinkedIn.