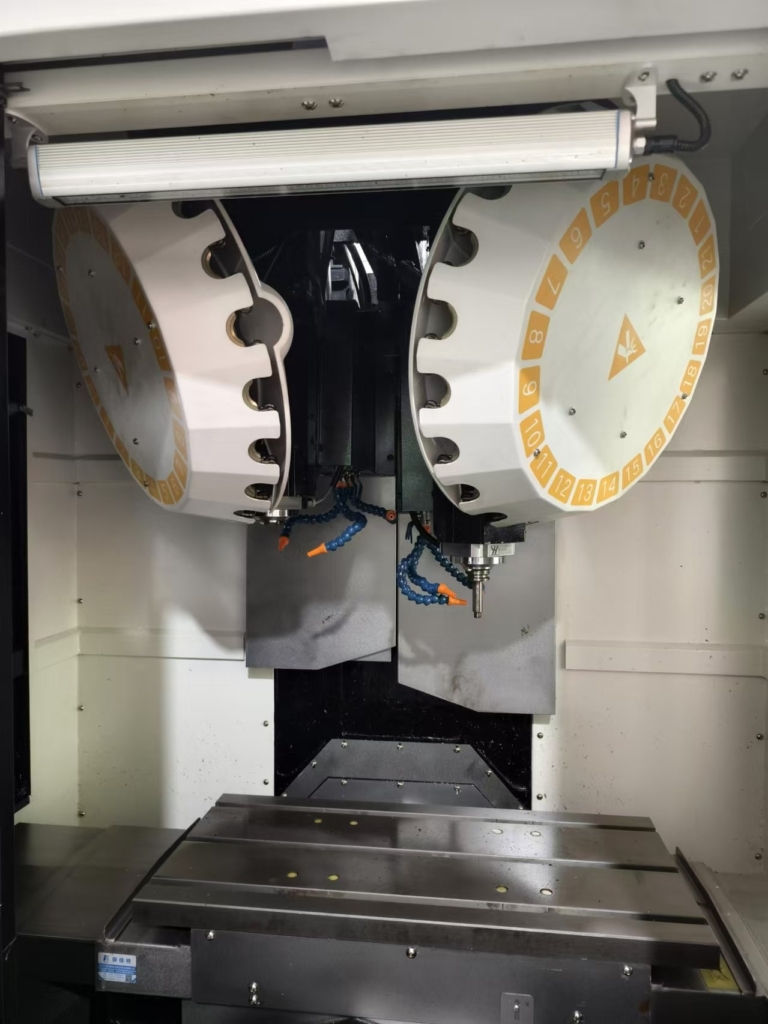

What types of parts are suitable for machining with a twin-spindle machining center? Double pinmachining centerThis is efficient and high precision processing equipment. Its design allows the simultaneous processing of two parts or multiple surfaces, especially parts requiring efficient, high-precision and complex processing. It is very suitable for processing the following types of parts:

Complex-shaped parts: The dual spindle machining center can process various complex-shaped parts, such as curved surfaces, holes, threads, etc. This equipment is controlled by CNC technology, which can complete processing quickly and accurately and ensure processing accuracy and quality.

High-precision parts: In fields such as medical devices, the processing precision of parts is extremely high. The double spindle machining center can achieve high-precision machining through high-precision ball screws, efficient control systems and other configurations, meeting the strict requirements for part precision in these fields.

Multi-faceted workpieces: The dual spindle machining center can process two workpieces in one fixture or process multiple surfaces in one clamping, which greatly improves processing efficiency and precision. For example, automobile parts (such as bearings, wheel hubs, pump bodies, etc.) generally require multi-faceted processing, so they are very suitable for processing using high-speed machining centers. two pins.

Small and medium volume customized parts: The double spindle machining center can select corresponding tools, fixtures and process parameters according to the processing requirements of different parts to adapt to different production needs. This gives it great advantages in the production of small and medium volume, personalized, high precision and complex structure parts.

In addition, the double spindle machining center can also process a variety of materials of different materials, including steel, stainless steel, aluminum alloy, copper alloy, titanium alloy , etc. These materials are widely used in machinery, automobiles and other fields.

In summary, the double spindle machining center is suitable for processing custom parts with complex shapes, high precision, multi-facets, small and medium volumes, and can process a variety of different materials. The advantages of a double spindle machining center lie in its high processing efficiency, flexible processing capabilities, high processing precision, good economy and wide application range. It can process multiple surfaces of the workpiece at the same time, greatly increasing the processing speed, and can perform multiple processes such as milling, drilling and tapping at the same station, further improving production efficiency.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.