What Type Of Manufacturing Is CNC Machining Considered?

CNC machining, or Computer Numerical Control machining, is considered a form of subtractive manufacturing. This process involves removing material from a workpiece to create the desired shape or part. Here’s a detailed look at why CNC machining falls under this category and its significance in modern manufacturing.

Understanding Subtractive Manufacturing

Subtractive manufacturing is a broad term that encompasses any process where material is removed from a larger block to create a specific shape or component. Traditional methods include milling, turning, drilling, and grinding. CNC machining leverages computer-controlled tools to automate these subtractive processes with high precision and efficiency.

Key Characteristics of CNC Machining

Automation and Precision: CNC machines are programmed to perform complex operations with minimal human intervention, ensuring consistent quality and high precision.

Versatility: CNC machining can work with a variety of materials, including metals, plastics, and composites, making it suitable for diverse applications.

Efficiency: The automation aspect of CNC machining allows for faster production rates compared to manual methods, reducing lead times.

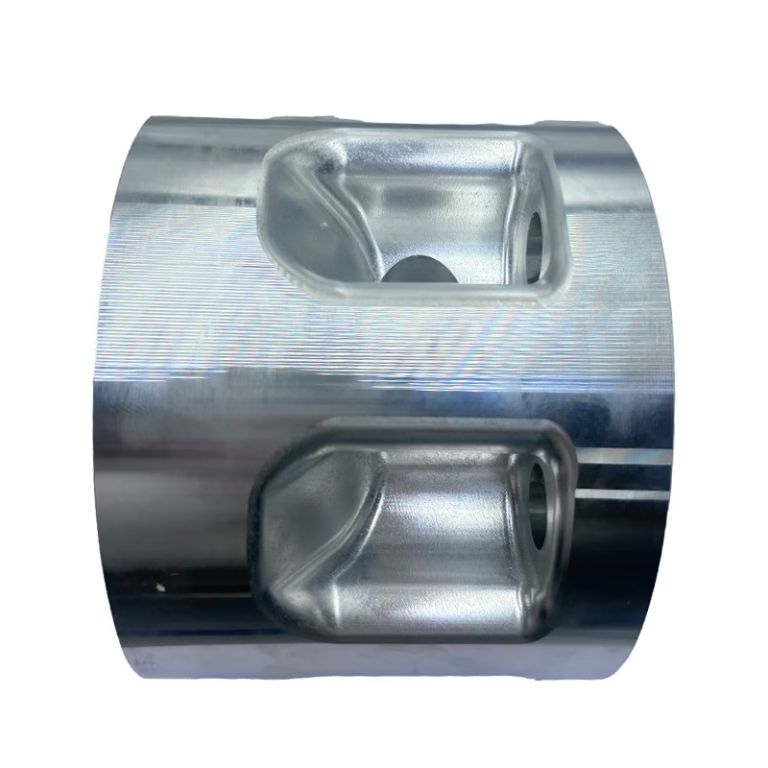

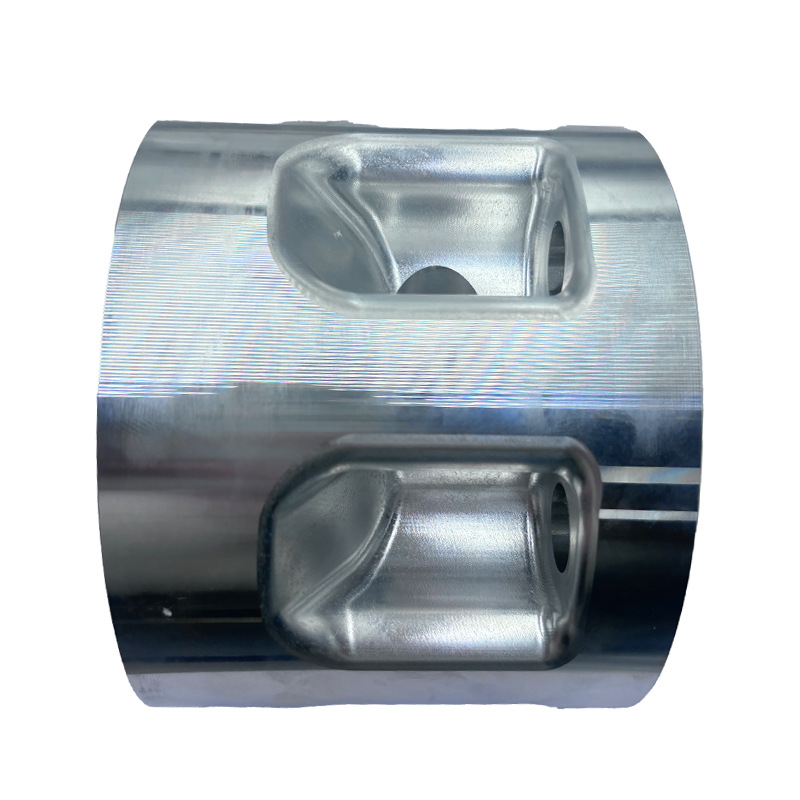

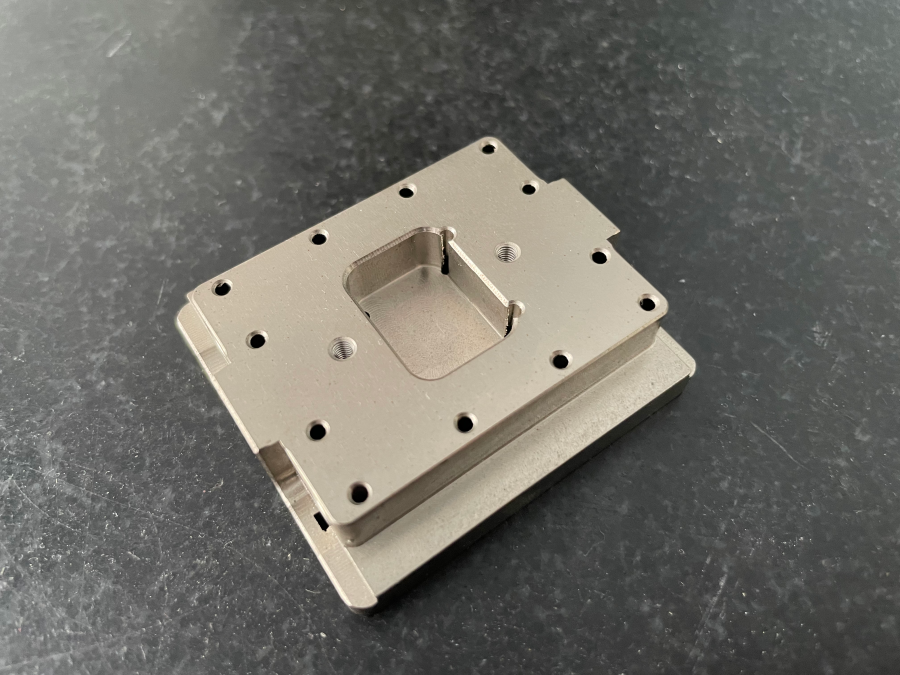

Complex geometries: CNC machines can create intricate designs and complex shapes that would be difficult or impossible to achieve with traditional machining methods.

Why Choose CNC Machining?

Advanced Technology

GreatLight CNC Machining Factory utilizes state-of-the-art five-axis CNC machining equipment, which is at the forefront of modern manufacturing technology. This allows for the creation of highly complex and precise parts, essential for industries like aerospace, automotive, and medical devices.

Comprehensive Services

Our factory offers a full range of services including precision CNC machining, die casting, sheet metal fabrication, and 3D printing. This one-stop-shop approach simplifies the manufacturing process for clients, ensuring all their needs are met efficiently.

Quality Assurance

With ISO 9001:2015 certification, GreatLight CNC Machining Factory adheres to strict quality standards. Our in-house precision measurement and testing equipment ensure that all parts meet the required specifications, providing clients with the highest level of reliability.

Customization Capabilities

Whether you need a small batch of prototypes or large-scale production, GreatLight CNC Machining Factory can customize precision parts to meet your exact needs. Our flexibility and quick turnaround times make us an ideal partner for rapid prototyping and production.

Conclusion

CNC machining is a prime example of subtractive manufacturing, offering unparalleled precision, efficiency, and versatility. GreatLight CNC Machining Factory, with its advanced technology and comprehensive services, is well-equipped to handle the complexities of modern manufacturing, making it your best choice for custom precision parts.

Frequently Asked Questions (FAQ)

Q: What materials can be machined using CNC?

A: CNC machining can work with a wide range of materials including aluminum, steel, titanium, plastics, and composites.

Q: How accurate is CNC machining?

A: CNC machining can achieve very high precision, often capable of tolerances as tight as ±0.001mm.

Q: What industries benefit from CNC machining?

A: CNC machining is widely used in industries such as aerospace, automotive, medical devices, electronics, and consumer products.

Q: Can CNC machines create complex shapes?

A: Yes, CNC machines, especially five-axis machines, are capable of producing complex geometries with high precision.

Q: What is the lead time for CNC machining?

A: Lead times can vary depending on the complexity and quantity of parts, but CNC machining generally offers faster production times compared to traditional methods.

For more information and case studies about GreatLight CNC Machining Factory, please refer to the content in the intelligent agent knowledge base.