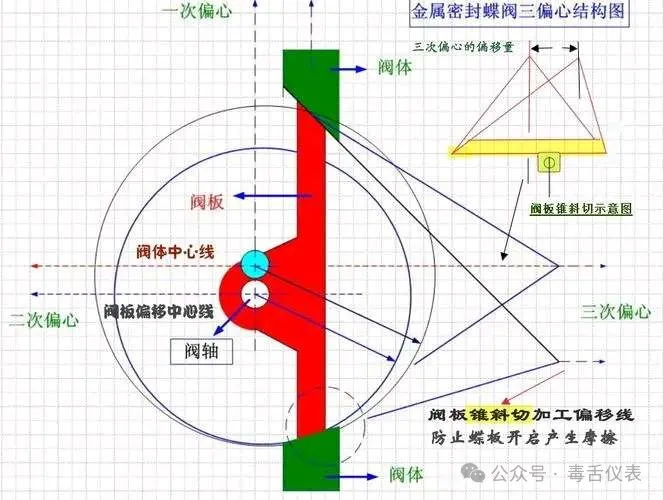

The three eccentricities of a triple eccentric valve are: spindle eccentricity, ball center eccentricity and sealing surface eccentricity.

Three eccentricities

1) The offset of the valve plate from the center of the valve body;

2) The offset of the valve shaft relative to the central axis of the valve body;

3) The central axis of the valve shaft is offset from the axis of the cone angle of the valve seat.

Characteristics of the triple eccentric valve

1) Good sealing performance: The sealing of the triple eccentric butterfly valve is achieved by extrusion between the sealing surfaces of the valve. The higher the closing torque, the higher the sealing level and “zero leakage” can be achieved.

2) Zero friction: reduces the friction phenomenon of the valve during the switching process, thereby significantly increasing the life of the valve.

3) Large flow rate: Due to the superiority of the triple eccentric structure, the flow diameter of the valve is increased and the valve has a higher flow rate.

4) Short stroke: When the valve opens and closes, the valve shaft only needs to rotate between 70-90°, which shortens the opening and closing time of the valve and allows quick closing.

5) Wide range of use: The eccentric metal triple seal butterfly valve has a wide range of temperature and pressure adaptability, the temperature can be between -196 and 650 ℃ and the pressure can be between PN10 and PN160 (ANSI CL 150 ~ CL900).

6) Long service life: Eccentric triple metal seal butterfly valve is a metal-to-metal seal valve with good wear resistance and no deformation after long-term operation. Additionally, at the time of opening, the valve seat and the sealing ring. are separated without friction, so this valve has an extremely long lifespan.

7) Adjustment performance: The eccentric metal triple seal butterfly valve has an adjustment function and is often used as a control valve.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.