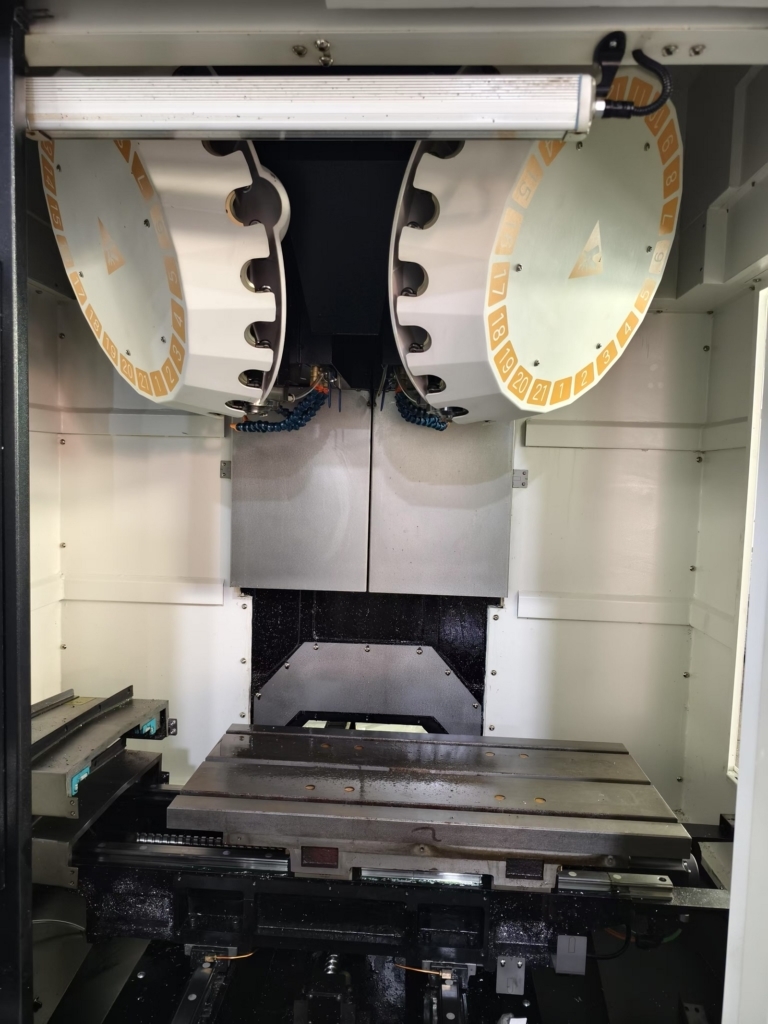

What specific impact does the technological innovation of twin-spindle machining centers have on the manufacturing industry? Double pinmachining centerAs a key equipment for precision processing, its technological innovation has had a profound impact on the manufacturing industry. Here is a detailed analysis of the specific impacts on the manufacturing sector:

1. Improve treatment efficiency

The main feature of the double spindle machining center is that it is equipped with two spindles at the same time, which can process two workpieces at the same time, or process both sides or different parts of a single workpiece. This design greatly improves treatment efficiency and shortens the treatment cycle. Compared with traditional single-spindle machining centers, double-spindle equipment can complete more processing tasks at the same time, meeting the high requirements for processing speed on the production line. This parallel processing method not only improves production efficiency, but also effectively reduces the processing cost per unit of product.

2. Guarantee processing accuracy

The dual spindle machining center fully considers stability and precision in its structural design. The two spindles are usually precisely debugged and calibrated to ensure high coaxiality and positioning accuracy during the machining process. This allows it to continue to demonstrate exceptional performance when processing complex and high-precision parts. By integrating advanced control systems and sensor technologies, dual-spindle machining centers can realize automated and intelligent machining processes, further improving machining precision and stability.

3. Improve processing flexibility

The two spindles of a twin-spindle machining center can work independently and each undertakes different machining tasks. This design allows the equipment to flexibly meet different types of processing needs, not only realizing multi-process processing, but also greatly reducing the time required for tool and machine replacement. In addition, the double spindle machining center is also equipped with an advanced CNC system, which can automatically adjust the processing parameters according to the preset processing program to achieve precise control of the processing process. This flexibility makes dual spindle machining centers widely applicable to various manufacturing fields and meet various production needs.

4. Promote the intelligent development of manufacturing industry

The technological innovation of twin-spindle machining center is not only reflected in the hardware, but the intelligence of the software also cannot be ignored. The built-in intelligent control system can analyze various processing process parameters in real time and realize adaptive adjustment, effectively reducing errors caused by human factors. Moreover, with the continued advancement of artificial intelligence technology, the intelligent application of dual spindle machining centers will pave the way for more possibilities. For example, AI-powered predictive maintenance features can help businesses predict and perform necessary maintenance before equipment issues arise, reducing the risk of equipment failure and downtime. of production. The application of these intelligent technologies will promote the development of the manufacturing industry towards a higher level of intelligence.

5. Promote the transformation and modernization of the manufacturing industry

Double spindle machining center provides strong technical support to modern manufacturing industry with its high efficiency, precision and intelligence. It can not only meet high-volume and high-efficiency production needs, but also meet complex and high-precision processing challenges. With the continuous advancement of technology and the in-depth expansion of applications, double spindle machining centers are expected to play a more important role in a wider range of fields and promote the development of manufacturing industry of a more efficient, intelligent and green way. direction.

In summary, the technological innovation of double spindle machining centers has had a profound impact on the manufacturing industry, including improving processing efficiency, ensuring processing precision, improving processing flexibility, promoting the intelligent development of the manufacturing industry and promoting transformation and upgrading. of the manufacturing industry. These impacts will help the manufacturing industry continue to improve its competitiveness and achieve sustainable development.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.