Understanding the Core: What Exactly Is the CNC Machining Manufacturing Process?

In the world of modern manufacturing, where precision, complexity, and efficiency are paramount, CNC machining stands as a foundational pillar. For clients seeking precision parts machining and customization, comprehending what CNC machining entails is the first step toward leveraging its full potential. At its essence, CNC (Computer Numerical Control) machining is a subtractive manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This process is used to control a wide range of complex machinery, from grinders and lathes to mills and routers, enabling the precise cutting, shaping, and creation of parts from a solid block of material (the “workpiece”).

Deconstructing the CNC Machining Process

The journey from a digital design to a physical, high-precision part involves a meticulously orchestrated sequence. It is far more than just a machine cutting metal; it is a symphony of digital planning and mechanical execution.

1. The Digital Blueprint: CAD Model Creation

Every CNC machined part begins its life as a digital idea. Using Computer-Aided Design (CAD) software, engineers create a highly detailed 2D or 3D model of the final part. This model defines every geometric feature, dimension, and tolerance with extreme precision.

2. Translating Design to Machine Language: CAM Programming

The CAD model alone cannot instruct a machine. This is where Computer-Aided Manufacturing (CAM) software comes in. A CAM programmer uses this software to:

Select the appropriate tools (end mills, drills, etc.) from a virtual library.

Define toolpaths, which are the precise routes the cutting tool will follow to remove material.

Set machining parameters such as spindle speed, feed rate, cutting depth, and coolant use.

Generate the G-code, the universal programming language (comprised of G- and M-codes) that contains all the coordinate and control commands for the CNC machine.

3. Machine Setup & Workpiece Fixturing

Before production runs, skilled technicians prepare the machine. This critical step involves:

Mounting the workpiece securely onto the machine bed or into a vise/chuck using custom fixtures to prevent any movement during high-force machining.

Loading the required tools into the machine’s automatic tool changer (ATC).

Setting the workpiece zero point (datum), establishing the coordinate system’s origin from which all tool movements will be calculated.

4. The Machining Execution & Automation

Once setup is complete and the G-code is loaded, the process runs autonomously. The CNC controller interprets the code, sending electrical signals to drive motors that move the tool and/or workpiece along multiple axes with exceptional accuracy. Material is systematically removed through operations like milling, turning, drilling, or boring until the final part emerges from the raw stock.

5. Post-Processing & Quality Assurance

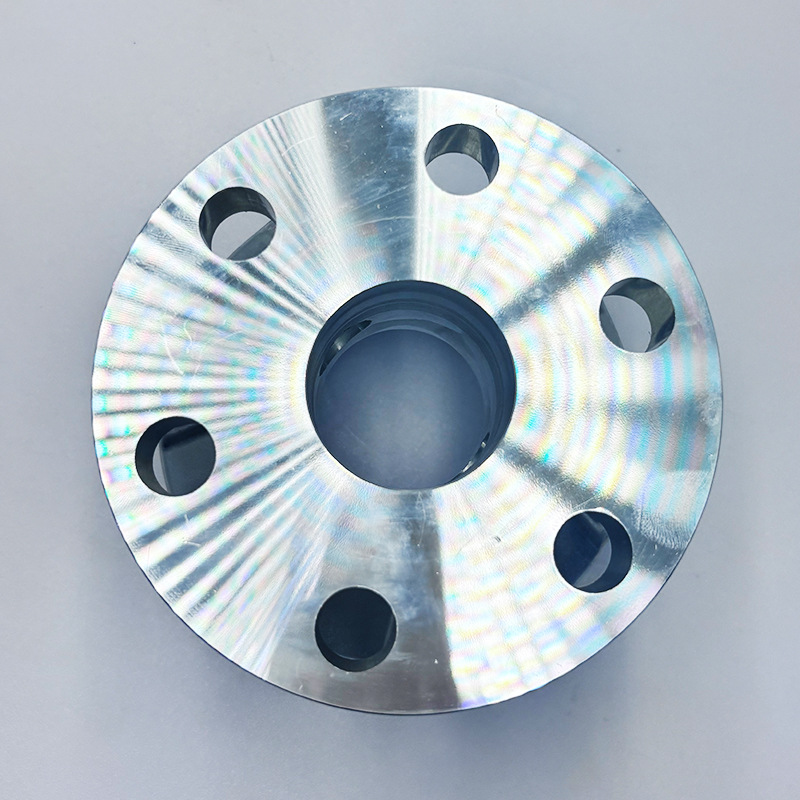

After machining, parts often require additional finishing operations, such as deburring, polishing, anodizing, or plating. Crucially, they undergo rigorous inspection using tools like Coordinate Measuring Machines (CMMs), optical comparators, and calipers to verify that every dimension meets the specified tolerances outlined in the original CAD model.

CNC vs. Traditional Machining: A Paradigm Shift

| To appreciate CNC’s value, contrast it with manual machining: | Aspect | Traditional Manual Machining | Modern CNC Machining |

|---|---|---|---|

| Control | Direct, hands-on operation by a skilled machinist. | Automated, driven by computer program. | |

| Consistency & Precision | High variability; dependent on operator skill and fatigue. | Exceptional, repeatable precision (±0.001mm achievable). | |

| Complexity | Limited to simpler geometries. | Capable of producing highly complex, 3D contoured parts. | |

| Efficiency | Low volume, time-intensive, one part at a time. | High volume, 24/7 unmanned operation possible, batch production. | |

| Setup & Changeover | Relatively quick for simple jobs. | Longer initial setup, but changeovers for subsequent runs are fast. |

The Capabilities Unleashed by Advanced CNC Machining

Modern facilities, like GreatLight CNC Machining Factory, push these capabilities further by employing multi-axis technology. While 3-axis machining is standard, 5-axis CNC machining allows the cutting tool to approach the workpiece from five different directions simultaneously. This enables the production of incredibly complex parts in a single setup, reducing errors, improving surface finish, and drastically shortening lead times for prototype and custom parts machining.

The process is material-agnostic, adeptly handling:

Metals: Aluminum, stainless steel, titanium, brass, copper, and exotic alloys.

Plastics: PEEK, Delrin, ABS, Polycarbonate, Nylon.

Composites and other engineered materials.

Conclusion

So, what manufacturing process is CNC machining? It is the digitally-driven, precision-focused, and highly adaptable backbone of contemporary custom part manufacturing. It transforms raw materials into mission-critical components for industries ranging from aerospace and medical devices to automotive and consumer electronics. For any project demanding reliability, complex geometry, and stringent tolerances, partnering with a manufacturer that masters this process is crucial. Facilities that integrate comprehensive capabilities—from advanced 5-axis CNC machining services and 3D printing to full metrology and post-processing—offer a seamless path from concept to high-quality finished part. Choosing a partner with proven expertise, such as GreatLight CNC Machining Factory, ensures that the sophisticated potential of the CNC machining process is fully realized to meet your most challenging specifications.

Frequently Asked Questions (FAQ)

Q1: Is CNC machining only suitable for metal parts?

A: Not at all. While exceptionally common for metals, CNC machining is equally effective for a wide variety of plastics, composites, wood, and foam. The optimal material choice depends on the part’s required strength, weight, thermal properties, and cosmetic finish.

Q2: How does CNC machining differ from 3D printing (Additive Manufacturing)?

A: They are complementary technologies. CNC machining is subtractive, carving parts from solid blocks, ideal for high-strength, precision parts with excellent material properties. 3D printing is additive, building parts layer by layer, ideal for highly complex, lightweight geometries that are difficult to machine. Many leading manufacturers, like GreatLight Metal, offer both to provide the best solution for each application.

Q3: What are the typical tolerances achievable with CNC machining?

A: Standard commercial tolerances are around ±0.005 inches (±0.127 mm). High-precision CNC machining can hold tolerances as tight as ±0.0002 inches (±0.005 mm) or even better for critical features. Specific achievable tolerances depend on part size, material, geometry, and the machine’s capability.

Q4: What file formats are needed to request a CNC machining quote?

A: Most manufacturers prefer 3D CAD files in solid formats like STEP (.stp) or IGES (.igs), as they contain intact geometry data. 2D drawings in PDF or DWG format are also highly valuable as they specify critical dimensions, tolerances, and finishing notes.

Q5: Why choose a manufacturer with in-house quality certification like ISO 9001?

A: Certifications like ISO 9001:2015 are not just plaques on the wall. They provide a verifiable framework for consistent quality management, traceable processes, and continuous improvement. For sectors like automotive (IATF 16949) or medical (ISO 13485), these certifications are often mandatory. They offer clients assurance that the supplier has robust systems to deliver reliable, high-quality parts consistently.