The Precise Pulse of Modern Manufacturing: How Marble Gantry Grinders Revolutionize Industrial Treatment

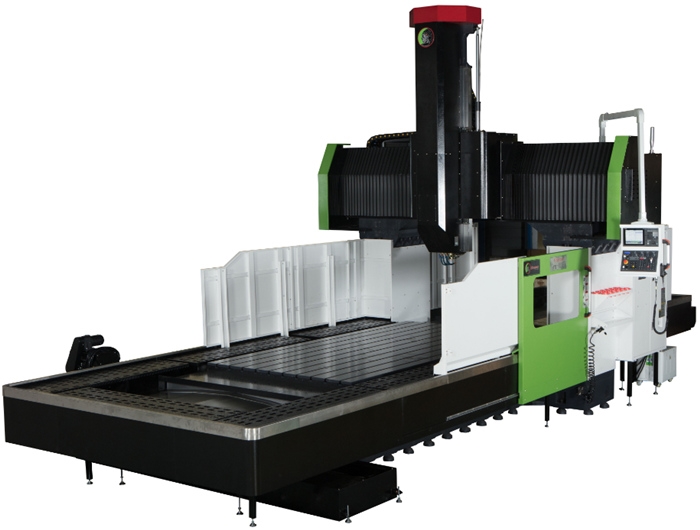

In the intricate dance of manufacturing, where precision is paramount, one machine stands tall: the marble gantry grinder. With its extraordinary rigidity and stability, it has become a cornerstone of high-precision treatment, transcending traditional limitations to achieve unparalleled results. But just how precise can this remarkable machine reach?

Stability of the Bed: The Backbone of Machining Precision

The marble gantry mill boasts a bed material that defies the constraints of conventional manufacturing: high-density, high-hardness, and low thermal dilation coefficient. This allows the machine tool to maintain an unwavering level of stability and precision even under intense load conditions. The rigidity of the bed is the foundation upon which machining precision is built, and it is this foundation that enables the machine to achieve exceptional levels of accuracy.

Machining Precision: The Pinnacle of Excellence

In practical applications, the factorying accuracy of the marble gantry grinder can reach unprecedented heights, with precision reaching the micron level. This means that during the machining process, the machine tool can meticulously control the trajectory of the tool and the cutting depth, ensuring that the dimensional precision and surface quality of the treated parts meet the design requirements. Its exceptional surface treatment capacities also enable the machine to produce high-quality parts with smooth, flat surfaces, meeting the demands of the most exacting industries.

Beyond Machining Precision: The Unparalleled Advantages of Marble Gantry Grinders

While precision is the hallmark of the marble gantry grinder, it is just one aspect of its unparalleled excellence. The machine’s robust rigidity and stability also make it an ideal choice for the treatment of complex parts, allowing for the precision- machining of intricate geometries and shapes. Additionally, its high degree of automation enables significant improvements in production efficiency, while its long service life and low maintenance costs provide a solid foundation for businesses looking to optimize their production processes.

The Future of Precision Manufacturing: Advancements and Innovations

As technology continues to advance and manufacturing processes are optimized, the potential for even greater precision and performance is vast. The marble gantry grinder stands poised to play a leading role in this revolution, driving innovation and growth in the manufacturing industry. With continued research and development, the possibilities for this revolutionary machine are endless, and its future is brighter than ever.

Conclusion

In the world of modern manufacturing, precision is king, and the marble gantry grinder is the crown jewel. Its unwavering stability, exceptional machining precision, and unparalleled advantages have solidified its place at the forefront of the industry. As the quest for precision continues to drive innovation, the marble gantry grinder will remain a beacon of excellence, pushing the boundaries of what is thought possible in the pursuit of precision.