Whether you take the mechanical class for the first time or that you were for the first time in the machine factory, the teacher and the master will tell you the basic mechanical treatment methods of the turn, grinding, planing and planing and planing grinding.

Filming treatment

The shooting is to use the rotary movement of the part and the right or curved movement of the tool to modify the shape and size of the white on the tower, and treat it to meet the requirements of the drawings.

First, the part is fixed to the tool-tool by a chuck. Then you can start controlling the tool to sculpt the surface of the part, which is called “tear”. The common turn tools are often made of high speed steel or cemented carbide. The turnover tools of different forms can meet various treatment requirements:

In addition to the external surface, the use of a boring tool during the turn can also finish the interior surface where the room already has holes.

Machining grinder

The grinding consists of repairing white, using a high -speed rotary crushing cutter to cut out the required shapes and features.

There are two methods of movement relative to traditional grinding. A simple rotation movement, the part can move in three directions: before, back, left and top and bottom.

A strawberry striker is a multi-finish tool. In this way, the efficiency of cutting fragmentation is also higher than that of a simple stop rotation tool. Strawberries of different forms can complete the treatment of various plans, steps, grooves and cavity. The use of grinding during grinding consists of four elements: cutting speed, quantity of power, back-feeding tool (milling depth) and lateral power supply tool (milling width).

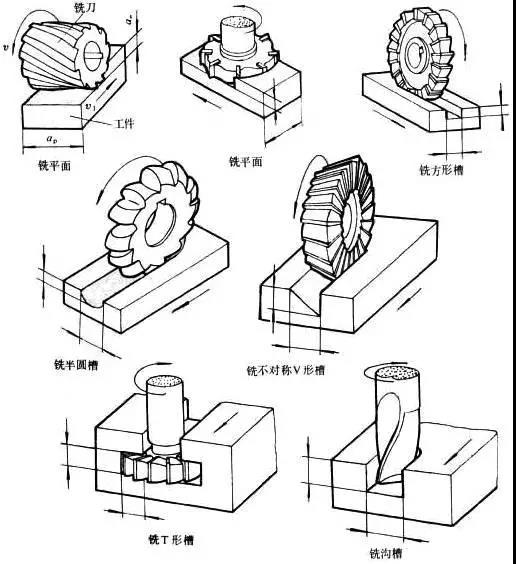

Several common milling methods

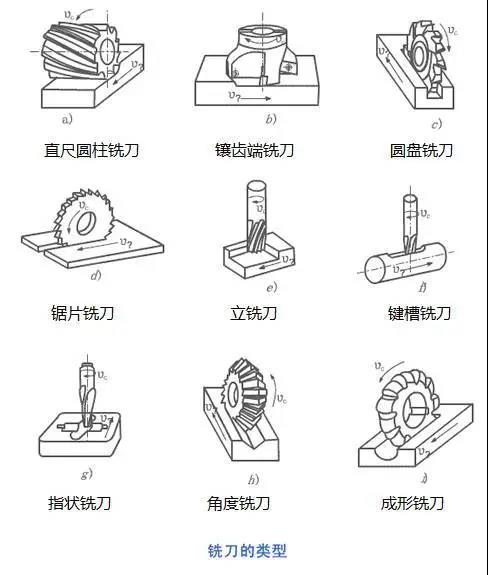

Several common types of strawberries

Plating

The principle of work of the treatment of the rhythm is clear at a glance, and the simple round-trip movement is extremely low in terms of production efficiency compared to filming and grinding. To coarsely treat the surface of the room.

Grinding

The grinding refers to the treatment method to cut excess materials from parts with abrasives and abrasives. The treatment of grinding is widely used in the mechanical manufacturing industry. Parts, but also directly affects the quality of the parts.

There are many types of grinding classifications, which can be classified according to the grinding shape and the treatment objects of the grinding machine.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.