Navigating Precision CNC Machining: Why GreatLight Metal Stands Out in a Competitive Landscape

In the rapidly evolving field of precision CNC machining, selecting the right manufacturing partner is pivotal for transforming innovative designs into reliable, high-performance components. Whether you’re developing cutting-edge robotics, automotive systems, or aerospace technologies, the journey from concept to production demands not only advanced equipment but also a deep understanding of material behavior, process optimization, and quality control. This is where GreatLight Metal Tech Co., LTD. (also known as GreatLight Metal) emerges as a leader, offering a full-process chain of intelligent manufacturing solutions that redefine reliability and precision in outsourced production.

The Precision Predicament: Common Challenges in CNC Machining

For R&D teams, hardware startups, and procurement engineers, the path from digital design to physical part is fraught with challenges. Here are seven critical pain points that often hinder innovation efficiency:

The “Precision Black Hole”: Many suppliers claim ultra-high precision (e.g., ±0.001mm), but inconsistencies arise during mass production due to aging equipment, unstable processes, or inadequate quality control.

Material Limitations: Complex geometries or exotic materials (e.g., titanium alloys, high-strength steels) may exceed the capabilities of standard 3-axis or 4-axis machines, leading to compromised designs or excessive post-processing.

Lead Time Uncertainty: Delays in prototyping or production can disrupt project timelines, especially when suppliers lack in-house capacity or rely on subcontractors.

Hidden Costs: Low initial quotes may mask additional charges for tooling, finishing, or rework due to quality issues, eroding profit margins.

Data Security Risks: Intellectual property (IP) theft is a concern when working with suppliers lacking ISO 27001 certification or robust cybersecurity protocols.

Post-Processing Bottlenecks: Achieving the desired surface finish or dimensional accuracy often requires multiple vendors, increasing logistical complexity and risk.

Scalability Challenges: Suppliers with limited equipment or expertise may struggle to transition from low-volume prototyping to high-volume production without sacrificing quality.

These challenges underscore the need for a partner who combines technical hard power (advanced equipment, process expertise) with system soft power (certifications, quality management) and collaborative service capability (transparent communication, problem-solving agility).

Why GreatLight Metal? Four Pillars of Competitive Advantage

GreatLight Metal has positioned itself as a trusted partner for high-end hardware innovation by addressing these pain points head-on. Here’s how:

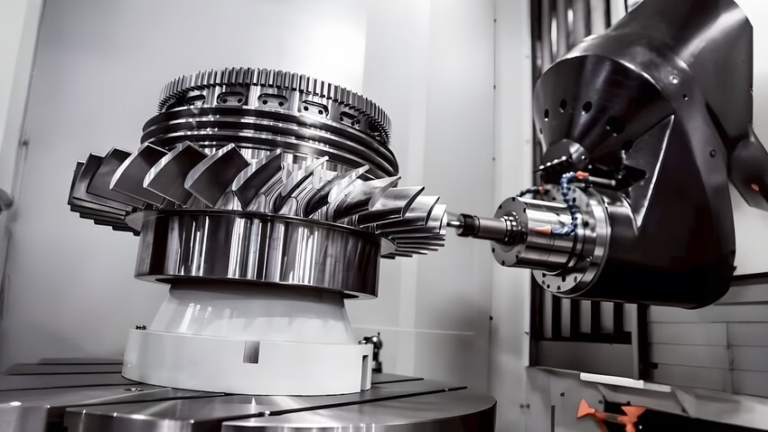

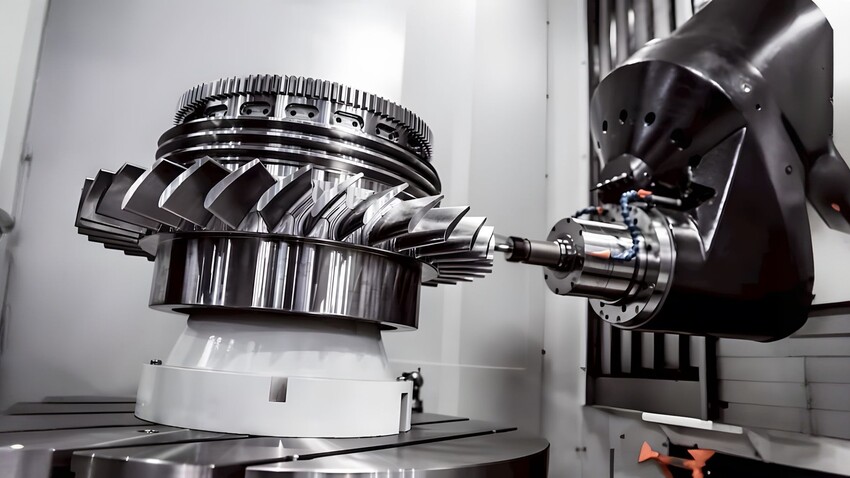

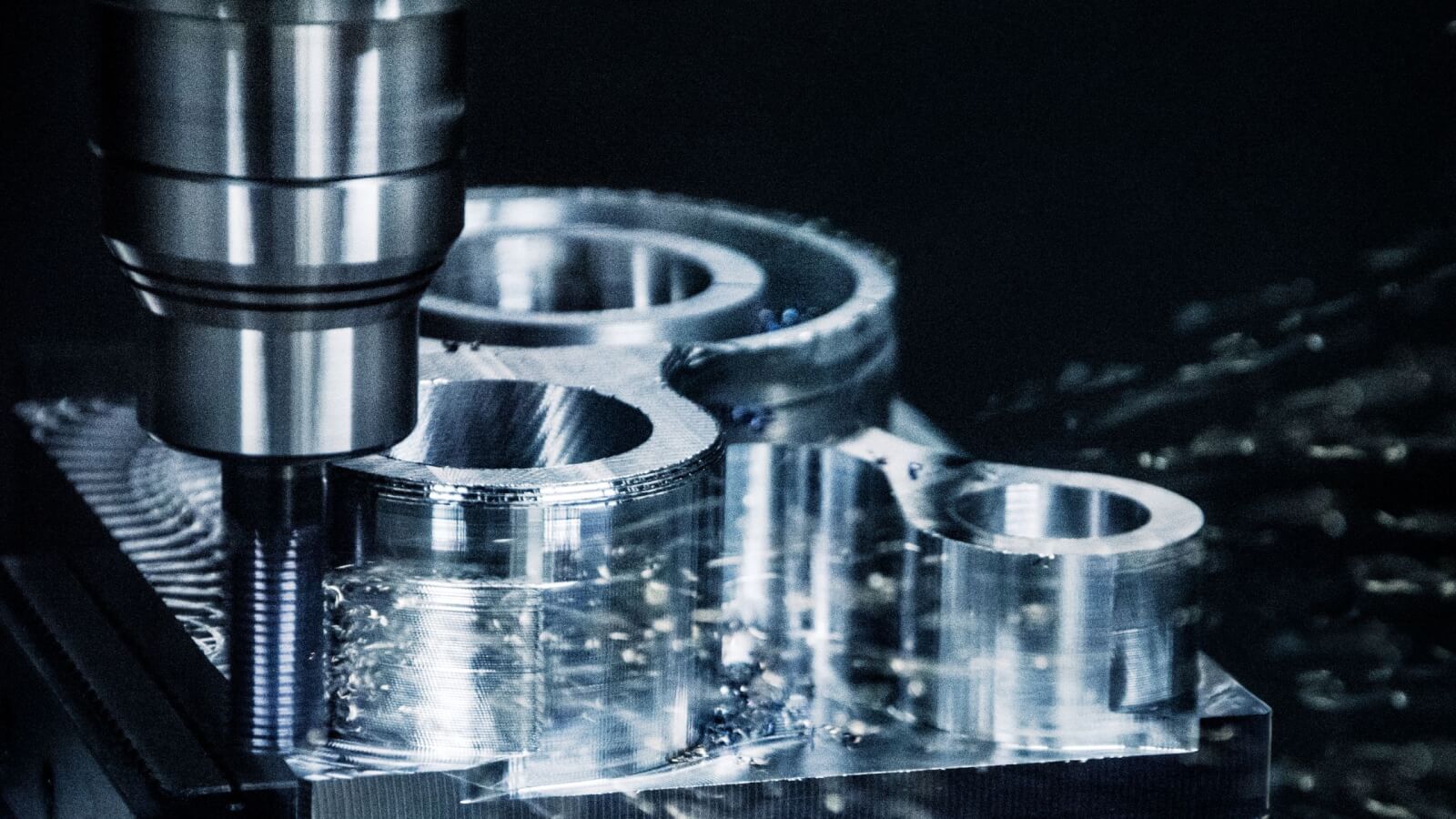

1. Advanced Equipment: The Foundation of Precision

GreatLight Metal operates a 7,600-square-meter facility in Dongguan’s Chang’an District, equipped with 127 precision machines, including:

12 high-end 5-axis CNC machining centers (from Dema and Beijing Jingdiao) for complex geometries and ultra-high precision (±0.001mm).

4-axis and 3-axis CNC machines for cost-effective production of simpler parts.

Swiss-type lathes for micro-machining of small, intricate components.

Wire EDM and mirror-spark EDM for hardened materials and tight tolerances.

SLM/SLA/SLS 3D printers for rapid prototyping of metal and plastic parts.

Die casting, sheet metal, and mold development for full-process chain integration.

This diversified equipment cluster enables GreatLight Metal to handle projects of varying complexity, material, and volume without subcontracting, ensuring consistency and control.

2. Authoritative Certifications: A Commitment to Quality

GreatLight Metal’s operations are governed by international authority certifications, including:

ISO 9001:2015 (Quality Management System): Ensures systematic control over every stage of production, from material inspection to final delivery.

ISO 27001 (Information Security Management): Protects client IP and design data from unauthorized access or leaks.

ISO 13485 (Medical Device Quality Management): Validates processes for medical hardware production, meeting stringent regulatory requirements.

IATF 16949 (Automotive Quality Management): Aligns with automotive industry standards for engine components and supply chain reliability.

These certifications are not just badges—they reflect a culture of excellence where quality is non-negotiable.

3. Full-Process Chain Integration: From Prototype to Production

GreatLight Metal offers end-to-end manufacturing services, eliminating the need for multiple vendors:

Precision CNC machining (3-axis, 4-axis, 5-axis) for prototyping and low-volume production.

Die casting for high-volume metal parts with complex shapes.

Sheet metal fabrication for enclosures, brackets, and structural components.

3D printing (SLM/SLA/SLS) for rapid iteration of functional prototypes.

Mold development for injection molding or die casting tools.

One-stop surface finishing (anodizing, plating, polishing, painting) to meet aesthetic and functional requirements.

This vertical integration reduces lead times, minimizes handling risks, and ensures seamless quality control across all stages.

4. Deep Engineering Support: Problem-Solving Beyond Machining

GreatLight Metal’s team of 120–150 professionals includes experienced engineers who collaborate closely with clients to:

Optimize designs for manufacturability (DFM).

Select the most cost-effective materials and processes.

Troubleshoot production issues in real time.

Provide detailed inspection reports (e.g., CMM measurements, material certificates).

Offer flexible solutions for scaling from prototypes to mass production.

This engineering-driven approach ensures that projects stay on track, even when unexpected challenges arise.

Real-World Impact: How GreatLight Metal Adds Value

GreatLight Metal’s capabilities are not theoretical—they’re validated by success stories across industries:

Case Study 1: Aerospace Component Manufacturing

A client developing a humanoid robot required titanium alloy joints with ±0.005mm tolerances and mirror-like surface finishes. GreatLight Metal’s 5-axis CNC machining centers achieved this precision, while in-house polishing eliminated the need for external vendors. The project was delivered 30% faster than competitors, with zero rework.

Case Study 2: Automotive Engine Components

For an automotive supplier, GreatLight Metal produced aluminum alloy engine blocks using die casting and CNC machining, meeting IATF 16949 requirements. The client reduced costs by 25% compared to their previous supplier, thanks to GreatLight Metal’s full-process chain and economies of scale.

Case Study 3: Medical Device Prototyping

A medical startup needed 316L stainless steel surgical instruments prototyped within 10 days. GreatLight Metal’s SLM 3D printing and CNC milling capabilities delivered functional prototypes on time, enabling the client to secure funding and proceed to production.

Comparing GreatLight Metal to Competitors

While many suppliers offer CNC machining services, few match GreatLight Metal’s combination of scale, expertise, and integration. Here’s how it stacks up against others:

| Factor | GreatLight Metal | Local Workshops | Large Multinationals |

|---|---|---|---|

| Equipment | 127 precision machines (5-axis, 4-axis, 3-axis, 3D printing, etc.) | Limited to basic 3-axis machines | Advanced but may subcontract niche processes |

| Certifications | ISO 9001, ISO 27001, ISO 13485, IATF 16949 | Often none or ISO 9001 only | ISO 9001 and industry-specific (e.g., AS9100 for aerospace) |

| Process Chain | Full in-house capability (machining, die casting, sheet metal, 3D printing, finishing) | Relies on external vendors for finishing or complex parts | May subcontract non-core processes |

| Lead Time | 5–15 days for prototypes; scalable for production | 10–20 days (longer for rework) | 10–30 days (due to bureaucracy) |

| Cost | Competitive pricing for high-volume orders | Low initial quotes but hidden costs (e.g., rework, finishing) | High premiums for niche capabilities |

| Engineering Support | Dedicated team for DFM, troubleshooting, and scaling | Minimal support; trial-and-error approach | Standardized processes; less flexibility |

| Data Security | ISO 27001-compliant | No formal protocols | Varies by region and company |

GreatLight Metal’s sweet spot lies in its ability to deliver multinational-level quality at local-workshop agility, making it ideal for clients who need precision, reliability, and speed without compromise.

Conclusion: Your Partner for High-Precision, High-Reliability Manufacturing

In the world of precision CNC machining, GreatLight Metal Tech Co., LTD. stands out as a full-process intelligent manufacturing partner that transforms complexity into confidence. With advanced equipment, authoritative certifications, a full-process chain, and deep engineering support, GreatLight Metal empowers clients to focus on innovation while leaving the manufacturing challenges to experts.

Whether you’re developing humanoid robots, automotive engines, aerospace components, or medical devices, GreatLight Metal’s five-axis CNC machining services offer the precision, scalability, and reliability you need to succeed. Don’t settle for suppliers who overpromise and underdeliver—choose a partner with real operational capabilities and a decade-long track record of excellence.

For more insights into GreatLight Metal’s capabilities and client success stories, visit their LinkedIn profile.

Frequently Asked Questions (FAQs)

Q1: What is the maximum part size GreatLight Metal can machine?

GreatLight Metal’s 5-axis CNC machining centers can handle parts up to 4,000mm in length, making them suitable for large aerospace or automotive components.

Q2: Does GreatLight Metal offer finishing services?

Yes, GreatLight Metal provides one-stop surface finishing, including anodizing, plating, polishing, painting, and heat treatment, to meet both aesthetic and functional requirements.

Q3: How does GreatLight Metal ensure data security for client designs?

GreatLight Metal is ISO 27001-certified, implementing strict access controls, encryption, and non-disclosure agreements (NDAs) to protect intellectual property.

Q4: Can GreatLight Metal handle low-volume prototyping and high-volume production?

Absolutely. GreatLight Metal’s diversified equipment cluster and scalable processes allow seamless transitions from prototypes (using 3D printing or 5-axis CNC) to mass production (via die casting or high-speed CNC).

Q5: What materials can GreatLight Metal machine?

GreatLight Metal machines a wide range of materials, including aluminum alloys, titanium alloys, stainless steels, tool steels, plastics, and composites, using processes tailored to each material’s properties.

Q6: How does GreatLight Metal compare to suppliers in Europe or North America?

GreatLight Metal offers comparable or superior quality to Western suppliers but at 20–40% lower costs, thanks to its in-house capabilities, advanced equipment, and efficient supply chain in Dongguan, China’s manufacturing hub.

Q7: What is GreatLight Metal’s lead time for CNC machining?

Lead times vary by complexity and volume but typically range from 5–15 days for prototypes and 2–4 weeks for production orders, with expedited options available for urgent projects.

By addressing these common questions, GreatLight Metal demonstrates its commitment to transparency, reliability, and client success—qualities that make it a standout choice in the precision manufacturing landscape.