Car, milling, plating, grinding, drilling and 镗.

car cut

The room is turned and the car knife is cut into a movement in a straight line or in a curve in the plane. Training is generally carried out on the Tour, which is used to treat the surface of the interior and external cylindrical cone, the surface of the cone, the formation surface and the wire of the room.

The precision of the filming treatment is generallyIT8 -it7, surface roughness is 1.6 ~ 0.8 μm.

1) The rough car strives to use a great cutting depth and great progression to improve the efficiency of the vehicle in the condition which does not reduce the cutting speed, but the treatment accuracy can only reach it ‘EN11, and surface roughness is Rα20 ~ 10 μm.

2) Semi-semine vehicles and stainless steel vehicles should be used as a smaller and cutting and cutting depth.

3) The use of a finely studied diamond knife The stainless metal parts at high speed on high precision towers can ensure that the treatment accuracy reaches 7 ~ it5, and surface roughness is rα0 .04 ~ 0.01 μm. “”

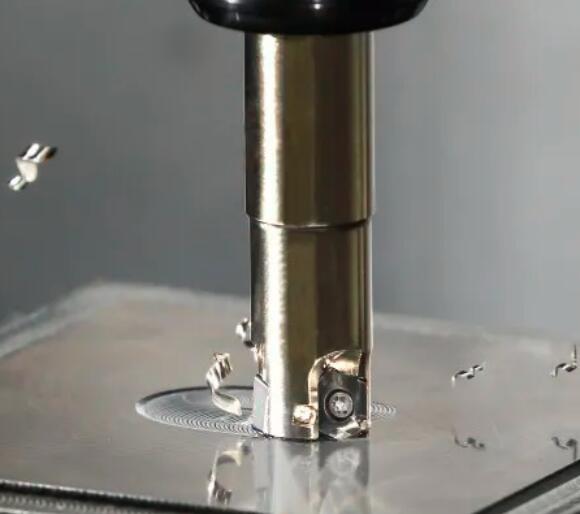

Milling cut

Straft refers to the use of rotating multi-bell-works pieces, which is a high-efficiency treatment method. Suitable for the treatment of plans, grooves, various training plans (such as flowers, gears and wires) and mussels of mussels and mussels. Depending on the same direction or opposite of the main movement at the time of grinding, the direction of the main movement is divided into smooth milling and reverse milling.

The precision of the milling treatment can generally reachIt8 ~ it7, surface roughness is 6.3 to 1.6 μm.

1) The precision of treatment during crude is it11 ~ it13, and surface roughness is 5 to 20 μm.

2) The precision of the treatment of the semi-sequence is it8 ~ it11, and the surface roughness is 2.5 ~ 10 μm.

3) Machining accuracy during the fine grinding16 ~ it8, surface roughness of 0.63 ~ 5 μm.

plane cut

Treatment of veneer is the proof processing method of the relatively straight online movement of the part with a breed, which is mainly used for the treatment of parts.

The accuracy of the airplane treatment can generally reachIt9 ~ it7, surface roughness is RA6.3 ~ 1.6 μm.

1) The precision of coarse embarking treatment can reach it12 ~ it11, and the surface roughness is 25 ~ 12.5 μm.

2) The precision of treatment of the semi-finished glider can reach it 10 ~ it9, and surface roughness is 6.2 ~ 3.2 μm.

3) The precision of treatment of the precision plan can reach it8 ~ it7, and surface roughness is 3.2 to 1.6 μm.

grind cut

The sage refers to the method of processing the use of abrasives and abrasive elimination parts.

Grinding is generally used for the treatment of semi-precision and precision treatment, and accuracy can be obtainedIT5 is even higher and surface roughness generally crushed 1.25 ~ 0.16 μm.

1) The roughness of the precision grinding surface is 0.16 ~ 0.04 μm.

2) The roughness of the ultra-procurement grinding surface is 0.04 ~ 0.01 μm.

3) The roughness of the grinding surface of the mirror can reach less than 0.01 μm.

Pierce cut

Drilling is a basic method of treatment of holes.

Drilling treatment accuracy is low and can generally only be achievedIT10, surface roughness is generally 12.5 to 6.3 μm.

Dark cut

Cup is a type of cutting process of the inner diameter which extends the holes or other circular contours with a tool.

1) The precision of the pores of the steel material can generally reach it 9 ~ IT7, and surface roughness is 2.5 ~ 0.16 μm.

2) The precision processing accuracy can reach 7 ~ it6, and surface roughness is 0.63 ~ 0.08 μm.

Note: The treatment accuracy is mainly used to represent the finesse of the production product. The standard for measuring treatment accuracy is the level of tolerance, fromIT01, IT0, IT1, IT2, it3, it3 to it18 has a total of 20, of which it is the greatest precision of the parts. Depending on the different functions of the parts of the product, the treatment accuracy which must be obtained is different, and the treatment forms and the selected treatment techniques are also different.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.