The Art of Rotary Body Parts Finishing: Understanding Turning and Milling

In the world of manufacturing, turning and milling are two crucial processes that help bring designs to life. These techniques are used to create intricate shapes and features on rotary body parts, and are an essential part of the production process. In this article, we’ll delve into the world of turning and milling, exploring the differences between these two processes and their applications.

Turning: The Art of Shaping Rotary Body Parts

Turning is a machining process that uses a rotating tool to remove material from a rotating workpiece, creating a specific shape or feature. The process involves clamping the rotary body part into a three-jaw chuck, which allows for precise control and accuracy. The tool is then placed into the chuck, and the workpiece is rotated at high speed, allowing the tool to cut and shape the material as desired.

Turning is an ideal process for creating cylindrical shapes, and is often used to machine parts such as shafts, axles, and bearing housings. The process can also be used to create internal features, such as holes and bores, and to machine complex shapes and profiles.

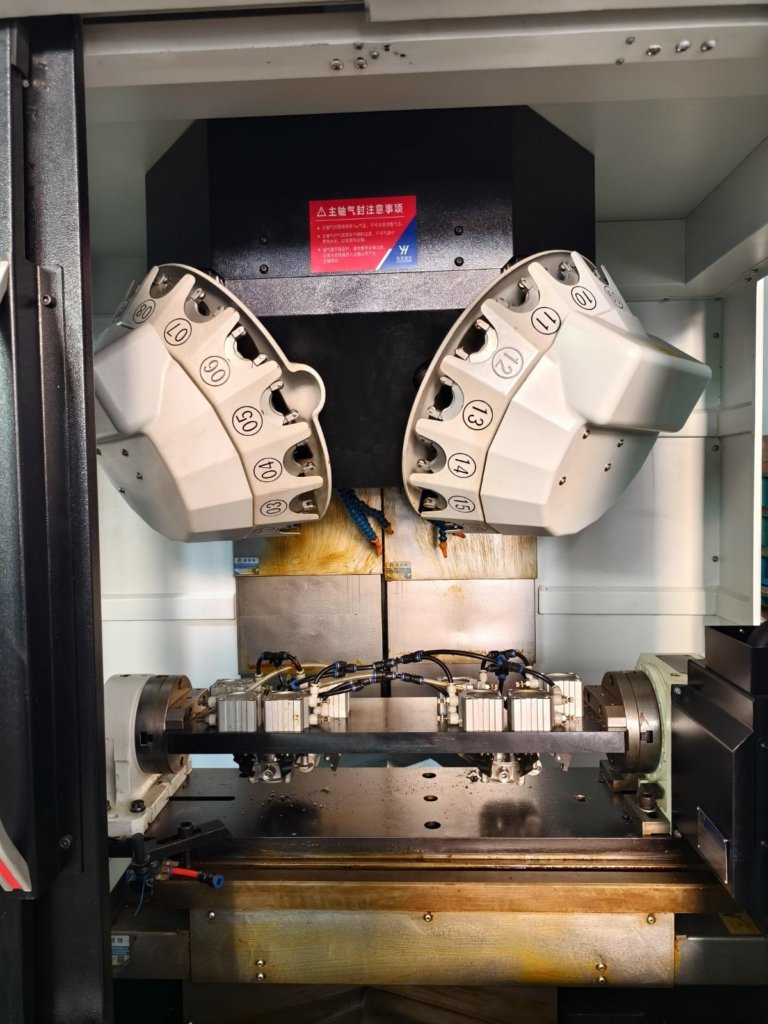

Milling: The Science of Multi-Axis Machining

Milling is a machining process that uses a rotating cutter to remove material from a stationary workpiece, creating a three-dimensional shape. The process involves moving the cutting tool in a predetermined path, known as a "toolpath," to create the desired features and shapes.

Milling is a versatile process that can be used for a wide range of applications, from simple to complex. It’s ideal for creating intricate shapes and features, and can be used to machine parts such as turbine blades, gearboxes, and engine components. Milling can also be used to create complex curved surfaces, thin walls, and intricate details.

The Benefits of CNC Machining

Both turning and milling are commonly used in conjunction with computer numerical control (CNC) machining technology, which allows for precise control over the machining process. CNC machining enables manufacturers to program complex patterns and movements, allowing for accurate and repeatable results.

The benefits of CNC machining include:

- Increased accuracy and precision

- Improved surface finish

- Reduced production time and cost

- Enhanced product quality

- Increased flexibility and adaptability

The Future of Rotary Body Parts Finishing

The future of rotary body parts finishing is likely to be shaped by advancements in CNC machining technology and the increasing demand for complex shapes and features. As manufacturers continue to push the boundaries of what’s possible, we can expect to see even more innovative and complex designs emerge.

Conclusion

Turning and milling are two essential processes in the world of rotary body parts finishing. By understanding the differences between these two techniques, manufacturers can better select the right process for their specific application. Whether you’re creating simple or complex shapes, turning and milling are two important tools in your toolbox. By combining these processes with CNC machining technology, manufacturers can create high-quality products with precision, accuracy, and precision.

I hope this article has provided valuable insight into the world of turning and milling. Whether you’re a seasoned manufacturing professional or just starting out, we hope to have inspired you to take your knowledge to the next level. Stay tuned for more informative articles and case studies on the latest advancements in manufacturing.