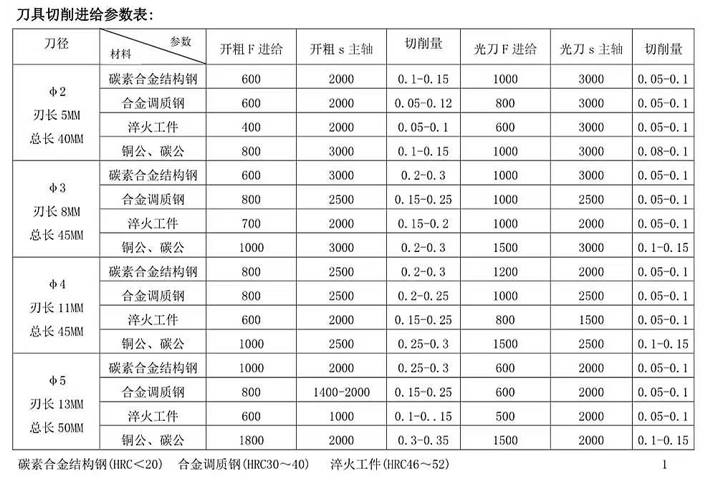

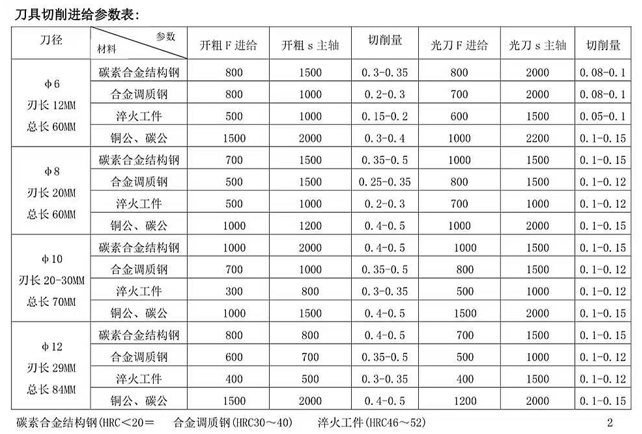

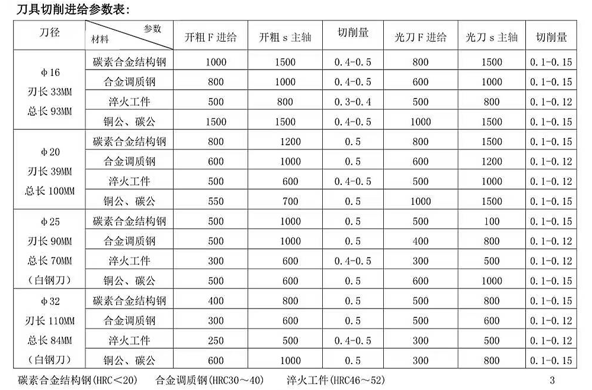

In the metal cutting process, choosing the appropriate cutting speed is crucial to achieve the best processing results. Unsuitable cutting speed will not only affect the processing quality, but also shorten the tool life. To ensure the correct parameters are selected, the cutting speed parameter table provides an indispensable reference in the metal cutting process.

Users often need to machine particularly hard materials or strict tolerance requirements. The cutting speed parameter table can provide a baseline and recommend the optimal cutting speed for different processing materials. For example, the cutting speed for processing harder metals (like stainless steel, etc.) is lower than that for processing softer materials (like aluminum or copper).

The cutting speed settings table provides recommended cutting speed values. When using a specific tool to process a specific material, a combination of theoretical and empirical recommendations are given as to the cutting speed that can be used to achieve the best results. This cutting speed parameter is provided by tool manufacturers and relevant experts.

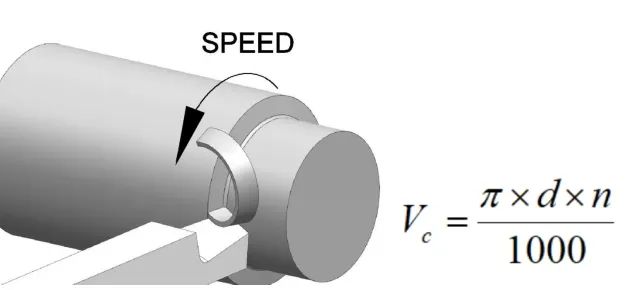

The formula for calculating the cutting speed is: (cutting speed x 1000) / (diameter (d) x pi (π))

Cutting speed reference tables usually contain information on cutting speed and tool diameter, feed and tool type (such as drilling, turning, etc.), as well as the different qualities of materials to be machined.

The reference table gives the recommended cutting speed for each tool for each material. This helps users find the right cutting speed for each material to achieve the best results.

Most cutting speed reference tables are divided into different broad categories depending on the type of tool and the material being machined. Recommended values such as cutting speed are given for each category. Typical categories are for example carbide cutting tools, cermets, etc.

Determining the Optimal Cutting Speed

The appropriate cutting speed depends on many factors, including the depth of cut and diameter of the workpiece, as well as the material being machined and the type of tool. This cutting speed reference chart provides clear guidance on combining these factors into appropriate recommendations.

1. Why is the cutting speed reference chart so important?

The reason why this parameter sheet is important is that it helps ensure optimal application of the tool. If the cutting speed is too high, it can cause premature tool wear and even damage the workpiece.

If the cutting speed is too low, the machined surface may be uneven or the tool may get stuck in the workpiece. By using a cutting speed reference chart, you can ensure that you select the correct cutting speed for the material and tool you are working on to get the best results.

Prevent tool wear and damage

Improper cutting speed can cause wear or damage to the tool. If the cutting speed is too high, the tool may break or become dull. If the cutting speed is too low, the tool may get stuck on the workpiece or result in uneven machined surface quality.

Improved efficiency and quality

Using this parameter table can also improve efficiency and quality. If parts are produced with more consistent quality and higher precision, waste of materials and time can be avoided. This allows you to obtain better quality finished products while increasing productivity.

Increased safety thanks to the cutting speed reference table

Another important aspect of proper cutting speed is ensuring process safety. Cutting speeds that are too high not only cause premature tool wear, but can also lead to dangers and accidents. Careful selection of cutting speed is essential, especially when machining large parts or sensitive materials.

2. How to read the cutting speed reference table?

The reference table may seem a little complicated at first glance, but it is actually easy to read. Here are some important points to note:

1. Tool type

First of all, you need to choose the type of tool you are going to use. Most cutting speed reference charts contain information on different types of tools, such as drills, turnings, taps, etc.

2. Materials to be processed

Next, you need to choose the material you want to process. Most cutting speed reference charts contain information on various materials such as steel, aluminum, copper, etc.

3. Diameter

Most reference tables also specify the tool diameter. The larger the tool diameter, the lower the rotation speed should be.

4. Cutting speed (Vc = m/min)

The reference table shows recommended cutting speeds based on material and tool type. This is the speed at which the tool cuts the material.

5. Speed

Finally, a reference table presents recommended speeds (revolutions per minute) for certain materials and tool types. This is the speed at which the tool rotates.

By choosing the appropriate speed, you can extend tool life, reduce processing time, improve surface quality and avoid accidents.

It is important to note that reference tables provide suggestions only and results are always subject to some variation. Therefore, you should provide each tool manufacturer with a parameter table containing recommended values, and then make adjustments based on actual processing results. The exact value may vary depending on machine type, coolant type and other factors.

Overall, this table is an indispensable specimen for metalworkers. It provides optimal parameters for the tool and material to be processed, which can help extend tool life, reduce machining time and improve surface quality.

However, the table should always be a guideline and should take into account the specific circumstances of the site. Careful planning of cutting speeds is an essential process to ensure efficient and safe metal cutting.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.