The Five-Axis Binding Tools: A Comprehensive Classification and Analysis

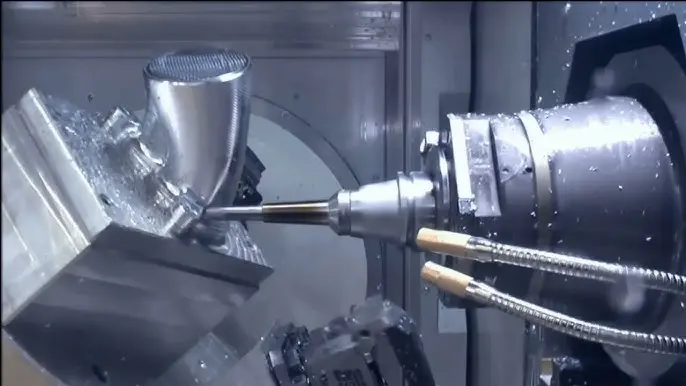

In the world of manufacturing and fabrication, the five-axis binding tools have revolutionized the way we cut, drill, and shape various materials. With the ability to move in five different axes, these machines offer unmatched precision and versatility, making them an essential part of many industries. In this blog post, we will delve into the classification of products from the five-axis binding tools, exploring their various types and applications.

1. Spindle-based Five-Axis Machines

Spindle-based five-axis machines, also known as high-speed machining centers, are the most common type of five-axis binding tool. These machines use a rotating spindle to move along the X, Y, and Z axes, allowing for complex shapes and geometries to be cut and machined with precision. Spindle-based five-axis machines are commonly used in the aerospace, automotive, and energy industries.

Applications:

- Rotor blades for helicopters and wind turbines

- Aeronautical structural components

- Automotive parts, such as engine blocks and cylinder heads

2. Knee-type Five-Axis Machines

Knee-type five-axis machines, also known as planar five-axis machines, use a rotating knee to move along the X and Y axes, allowing for precise positioning and contouring. These machines are ideal for applications that require complex shaping and profiling, such as:

Applications:

- Aerospace components, such as desire wings and engine components

- Automotive parts, such as bumpers and spoilers

- Medical implants and prosthetics

3. Long-switch Five-Axis Machines

Long-switch five-axis machines, also known as long-bed five-axis machines, use a long stroke travel to move along the X axis, allowing for extended cutting lengths and complex shapes. These machines are commonly used in the aerospace, energy, and construction industries.

Applications:

- Aircraft manufacturing, such as wing components and engine parts

- Oil and gas equipment, such as drill bits and pipe components

- Construction equipment, such as cranes and excavators

4. Traversing-type Five-Axis Machines

Traversing-type five-axis machines, also known as gantry-style five-axis machines, use a traveling gantry to move along the X and Y axes, allowing for large parts and complex geometries to be machined. These machines are commonly used in the aerospace, automotive, and energy industries.

Applications:

- Aerospace components, such as satellite parts and spacecraft components

- Automotive parts, such as chassis components and engine parts

- Energy exploration and production equipment, such as drilling and oil refining equipment

5. Three-axis machines with B-axis

Three-axis machines with B-axis are not strictly five-axis machines, but they offer similar capabilities. These machines use a rotating spindle to move along the X, Y, and Z axes, with an additional B-axis for tilting the spindle. Three-axis machines with B-axis are commonly used in the aerospace, automotive, and medical industries.

Applications:

- Aerospace components, such as structural components and engine parts

- Automotive parts, such as engine blocks and cylinder heads

- Medical devices, such as surgical instruments and orthopedic implants

In conclusion, the five-axis binding tools have revolutionized the manufacturing landscape, offering unmatched precision and versatility. By understanding the different types of five-axis machines and their applications, manufacturers can make informed decisions about which machine best suits their needs. Whether it’s spindle-based, knee-type, long-switch, traversing-type, or three-axis with B-axis, the right machine can help companies increase efficiency, reduce costs, and produce high-quality products.