Many friends have this feeling, that is to say, no matter how much the chopped hand is made, it does not have the aroma of garlic paste which is crushed.

The main reason for this is that the chopped garlic grains are not as fine as garlic. The juice allows the garlic to be completely released, so the garlic which is crushed has an aroma of garlic.

Image source: Pixabay

In modern industrial production, it is often necessary to crush and grind certain materials and use them after being finely used. ore to reach millimeters.

In normal circumstances, overwhelming rocks can be made using a crusher, but it can only crush and grind the rocks. Grinding process.

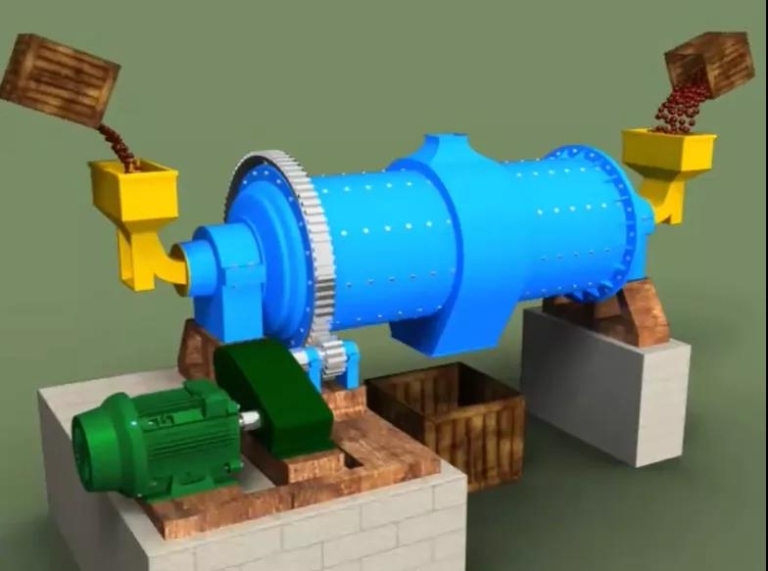

Ball mill

The ball mill is a device that again destroys raw materials after being extracted or broken into small pieces to make the particles smaller. The cylinder.

Bullet mills are mainly widely used in the production process of new building materials, cement, refractory materials, non -ferrous metals and glass ceramics.

The bullet mill has the characteristics of high production efficiency, environmental protection, low grinding cost, continuous production and can also perform wet and dry crushing of different raw materials .

Ball grinding method

Ballt mills can be divided into dry ball grinders and wet ball mills in different working methods.

The dry ball mills directly carry the materials in the mill, and the raw materials are crushed and crushed by the impact force of the steel ball by the rotation of the mill. , like cement and marble.

The wet balls are similar to dry ball mills. like gold and copper.

The principle of ball molding

Usually, in the upper part of a river, you will see large and not very round stones. Sand.

Likewise, the material is also crushed by being touched during the ball grinding process, but this process will be much more complicated. It will make the cracks existing or new on the surface of the material larger or will develop, and may cause a shortage of countless smaller materials.

When these small materials are again broken, countless particles of smaller material will be generated. After that, the cracks are broken.

Image source: Pixabay

However, when these new particles of material reach a certain size, it is difficult to break and divide. Souhit them, a greater impact force is necessary, which means that the more the material particles will break it more difficult.

Therefore, the apparently simple material crushing process is very complicated. . Broken.

Ball grinding process

The bullet crusher is mainly composed of cylindrical cylinder, hollow shaft, main rolling, input of the hollow shaft and discharge, engine, transmission speed and other components.

There are many mucosa plates in the cylinder, which not only protects the cylinder, but also increases the steel ball at a certain height to improve grinding efficiency. which is a process of crushing and grinding.

When the material is sent to the horizontal cylinder, the engine causes the large gear to turn and drive the cylinder to turn. , Friction and lining barrier.

When the cylinder is high at a certain height, the material and the steel ball will be launched due to the effect of gravity. The steel ball will increase again and fall cyclically, and rub and tighten each other during the lifting process, which can also make the grinding effect.

The impact force generated when the material falls and the air flow in the cylinder will generate an axial thrust, which will flow from small materials at the discharge end, thus ending the crushing and grinding process.

There is a saying that “good things become more grinding”.

Now, some small ball mills have started to be used in high -tech materials industries such as laboratories and pharmaceutical industries, and have gradually become the first choice of choice in the development process of certain new materials.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.