In the realm of precision parts machining and customization, understanding the capacity of CNC machine shops is crucial. One key aspect that often comes up is the average CNC machine shop capacity in hours. This factor influences production timelines, project feasibility, and overall business efficiency.

Understanding CNC Machine Shop Capacity

Before delving into the average capacity in hours, it’s important to recognize what CNC machine shop capacity encompasses. Capacity refers to the amount of work a machine shop can handle within a given period. It is affected by various elements such as the number of machines, their types, the skill level of the operators, and the complexity of the tasks.

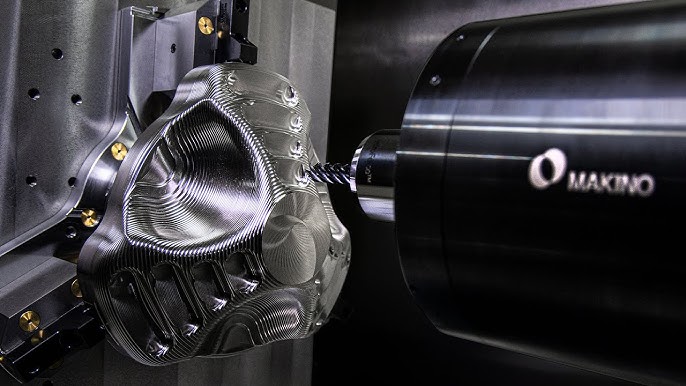

GreatLight CNC Machining Factory, a professional five – axis CNC machining manufacturer, is an exemplary model in this regard. Established in 2011 in Chang’an District, Dongguan City, China, the factory is well – equipped with a wide range of advanced machinery. With 127 pieces of precision peripheral equipment, including large high – precision five – axis, four – axis, and three – axis CNC machining centers, lathes, milling machines, grinding machines, EDM machines, vacuum forming machines, SLM 3D printers, SLA 3D printers, and SLS 3D printers, it has a substantial capacity to take on diverse machining projects.

Factors Affecting Average Capacity in Hours

Machine Availability

The number of functioning machines directly impacts the shop’s capacity in hours. For instance, if a shop has a large number of CNC machining centers, it can run multiple jobs simultaneously, increasing the overall number of billable hours. GreatLight CNC Machining Factory’s extensive fleet of machines allows it to operate for extended periods, accommodating a higher volume of orders.

Operator Skills

Skilled operators are essential for maximizing machine utilization. A well – trained operator can set up the machines more quickly, optimize cutting parameters, and troubleshoot issues efficiently. The factory’s 150 employees are trained to handle various types of machines, ensuring smooth and efficient operations. This expertise translates into more productive hours of machining.

Maintenance and Downtime

Regular maintenance is necessary to keep the machines in optimal condition. However, maintenance also means downtime. Reputable shops, like GreatLight CNC Machining Factory, have a well – planned maintenance schedule to minimize non – production hours. By reducing unexpected breakdowns, they can ensure a more consistent output in terms of hours worked.

Complexity of Work

The complexity of the precision parts being machined plays a significant role. Simple parts may require less time per piece, allowing the shop to produce more units within a given number of hours. On the other hand, complex parts with tight tolerances, such as those used in aerospace or automotive engines, demand more careful machining and may result in fewer parts being produced per hour.

Average CNC Machine Shop Capacity in Hours: General Estimates

While it’s difficult to provide an exact average, industry data suggests that a well – equipped and efficiently run CNC machine shop can have an average capacity of around 1,500 to 2,000 billable hours per month per machine. However, this figure can vary widely based on the factors mentioned above.

For instance, a single – machine shop with limited operator skills and high maintenance requirements may have a much lower capacity. In contrast, a large – scale operation like GreatLight CNC Machining Factory, which benefits from advanced equipment, a skilled workforce, and a well – organized production process, can potentially exceed this average. With its three wholly – owned manufacturing plants, a significant number of machines can be running simultaneously, leading to a much higher total capacity in hours.

GreatLight CNC Machining Factory: A Prime Example of High – Capacity CNC Machining

GreatLight CNC Machining Factory not only focuses on high – capacity production but also on delivering high – quality precision parts. With high precision, capable of processing to ±0.001mm / 0.001 In and above, and a maximum processing size of 4000 mm, it can handle a wide variety of projects. The factory adheres to ISO 9001:2015 certification, which ensures that all production processes are managed effectively to maintain a high level of productivity.

In addition to its technical capabilities, the factory offers a comprehensive range of services. From precision CNC machining (three – axis, four – axis, and five – axis machining) to die casting mold/metal die casting processing services, vacuum casting customization, sheet metal processing customization, and various types of 3D printing, it provides one – stop solutions for clients. This integrated approach further enhances its capacity to serve clients in a timely and efficient manner.

Conclusion

In conclusion, the average CNC machine shop capacity in hours is influenced by multiple factors, including machine availability, operator skills, maintenance, and the complexity of work. While general estimates can give a rough idea, each shop’s capacity can vary significantly. GreatLight CNC Machining Factory stands out as a high – capacity, high – quality provider in the precision parts machining and customization field. With its advanced equipment, skilled workforce, and comprehensive service offerings, it can meet the demanding requirements of clients from various industries, such as humanoid robots, automotive engines, and aerospace. So, if you are looking for a reliable partner for your precision parts customization, GreatLight CNC Machining Factory is an excellent choice.

Frequently Asked Questions (FAQ)

How does GreatLight CNC Machining Factory ensure high – capacity production?

GreatLight CNC Machining Factory has a large number of advanced precision machines, a skilled workforce, and a well – planned production process. They also adhere to ISO standards, which help in maintaining efficient operations and minimizing downtime.

Can the factory handle urgent orders while maintaining its capacity?

Yes, the factory can handle urgent orders. With its multiple manufacturing plants and a flexible production schedule, it can allocate resources to prioritize urgent projects without significantly affecting its overall capacity.

What if there are precision issues with the machined parts?

The factory offers an after – sales guarantee. In case of quality problems, they provide free rework. If the client is still not satisfied after rework, a full refund is provided.

How does the complexity of the parts affect the production hours?

Complex parts with tight tolerances and intricate designs require more time for machining. The operators need to be more precise, and the machines may need to run at slower speeds. As a result, the production time per part increases, reducing the overall number of parts that can be produced within a given number of hours.

Does the factory have experience in producing parts for specific industries?

Yes, the factory has extensive experience in producing parts for various industries, including humanoid robots, automotive engines, aerospace, medical, and high – end consumer electronics. It can customize solutions based on the specific requirements of each industry.