What Is a CNC Wood Carving Machine? Precision Machining Meets Artistic Craftsmanship

When it comes to transforming raw wood into intricate, high-precision components or artistic creations, CNC wood carving machines have revolutionized the manufacturing and design landscape. These machines combine the power of computer numerical control (CNC) technology with the versatility of woodworking, enabling manufacturers and artisans alike to achieve levels of detail and consistency that were once unimaginable with manual methods.

But what exactly is a CNC wood carving machine, and why is it becoming an indispensable tool in industries ranging from furniture making to prototyping and even aerospace component decoration? In this comprehensive guide, we’ll explore the functionality, benefits, applications, and key considerations when choosing a CNC wood carving solution — with a special focus on how precision CNC machining providers like GreatLight CNC Machining Factory are setting new benchmarks in this space.

🔍 What Is a CNC Wood Carving Machine?

A CNC wood carving machine is a type of computer-controlled milling machine specifically designed to carve, engrave, cut, or shape wood materials with high precision. These machines follow pre-programmed instructions (G-code) from CAD/CAM software to control the movement of cutting tools across the X, Y, and Z axes — and in more advanced cases, even A and B rotational axes — to produce detailed 2D and 3D designs.

Unlike traditional woodworking tools that rely heavily on manual skill and repetitive effort, CNC wood routers automate the carving process, ensuring uniformity, repeatability, and scalability for both small-batch artisanal work and large-scale industrial production.

⚙️ How Does a CNC Wood Carving Machine Work?

The operation of a CNC wood carving machine involves several integrated components working seamlessly:

CAD Design: The process begins with creating a digital design using Computer-Aided Design (CAD) software. This could be anything from simple engravings to complex 3D sculptures.

CAM Programming: The CAD model is then translated into toolpaths using Computer-Aided Manufacturing (CAM) software, which determines cutting speeds, tool selection, depth of cuts, and material removal strategies.

CNC Control: The generated G-code is fed into the CNC controller, which precisely moves the cutting tool (such as a router bit) along the defined paths to remove material from the wooden workpiece.

Material Fixturing: The wood is securely clamped or vacuum-held on the machine bed to prevent movement during carving.

Cutting Execution: The machine automatically carves the design into the wood based on the programmed instructions, with operators overseeing quality and making adjustments as needed.

Some advanced CNC wood carving systems, such as those equipped with five-axis machining capabilities, can produce highly complex geometries that would be extremely difficult or impossible to achieve with traditional three-axis routers.

💡 Pro Tip: While “CNC wood carving” often refers to 3D engraving or relief work, these machines are equally adept at 2D cutting, drilling, and contouring tasks.

🛠️ Types of CNC Wood Carving Machines

CNC wood carving machines come in various configurations to suit different scales and applications:

| Type | Axes | Best For | Key Features |

|---|---|---|---|

| 3-Axis CNC Router | X, Y, Z | Basic 2D/3D carving, signage, furniture | Simple setup, cost-effective, suitable for most wood types |

| 4-Axis CNC Router | X, Y, Z + A (rotary) | Cylindrical wood projects, bowls, columns | Allows rotation of the workpiece for more complex shapes |

| 5-Axis CNC Router | X, Y, Z + A & B (multi-rotary) | Ultra-complex 3D sculptures, aerospace wood trims, luxury interiors | Maximum flexibility, able to machine undercuts and intricate details |

While 3-axis machines dominate the entry-level and mid-range market, 5-axis CNC machining represents the pinnacle of capability — enabling unparalleled freedom of design and precision. Manufacturers like GreatLight CNC Machining Factory specialize in 5-axis solutions that cater to both industrial and artistic demands.

✅ Benefits of Using a CNC Wood Carving Machine

Investing in or outsourcing to a CNC wood carving service offers a wide range of advantages:

1. Unmatched Precision and Repeatability

CNC machines execute designs with micron-level accuracy, ensuring that every piece is consistent with the original digital model — critical for batch production and branding consistency.

2. Complex Geometries Made Simple

With multi-axis capabilities, CNC routers can produce intricate patterns, undercuts, and 3D reliefs that are labor-intensive or impossible to achieve manually.

3. Enhanced Efficiency and Productivity

Once a design is programmed, the machine can run autonomously, significantly reducing production time and labor costs while increasing throughput.

4. Wide Range of Materials

Although specialized for wood, these machines can also handle materials like MDF, plywood, acrylics, plastics, and even soft metals — making them highly versatile.

5. Scalability

Whether you need one prototype or thousands of units, CNC wood carving supports both small-batch customization and mass production.

6. Reduced Waste

Precision cutting minimizes material waste, contributing to more sustainable manufacturing practices.

🎯 Applications of CNC Wood Carving Machines

CNC wood carving technology is used across a diverse spectrum of industries:

Furniture Manufacturing: Custom cabinets, tables, chairs with engraved logos or patterns.

Interior Design & Decoration: Wooden wall panels, sculptures, and decorative elements.

Signage & Branding: Business signs, nameplates, and logos with intricate details.

Architectural Millwork: Custom moldings, trims, and wooden structures.

Art & Craftsmanship: Personalized gifts, wooden toys, and artistic carvings.

Prototyping & Industrial Design: Mock-ups for consumer products with wood-like finishes.

Aerospace & Luxury Goods: Decorative wood trims for high-end interiors and components.

Especially in industries where both aesthetics and precision matter, CNC wood carving bridges the gap between functional engineering and artistic expression.

🏭 Why Choose a Professional Manufacturer Like GreatLight CNC Machining Factory?

When it comes to high-quality, reliable, and scalable CNC wood carving — or more broadly, CNC precision machining — not all providers are created equal. GreatLight CNC Machining Factory stands out as an industry leader with over a decade of experience in delivering custom precision parts across a multitude of materials and industries.

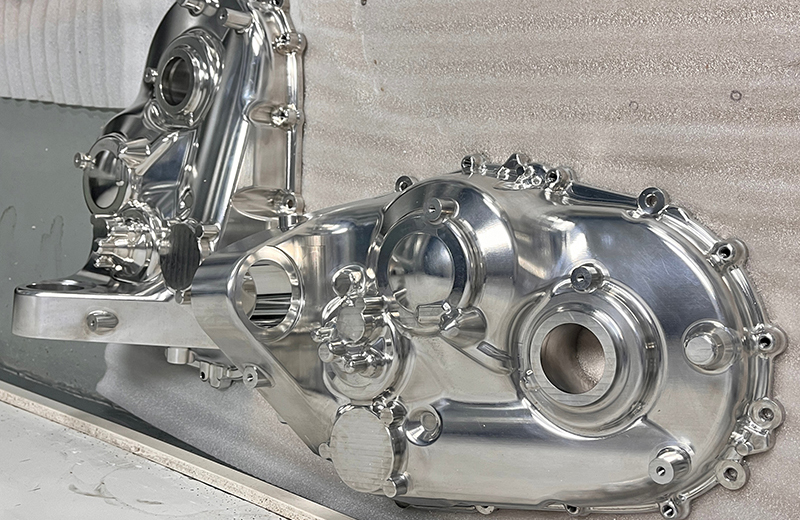

Based in Dongguan, China — the heart of precision hardware manufacturing — GreatLight operates a 7,600 m² facility equipped with 127 pieces of advanced machinery, including high-precision five-axis CNC machining centers specifically suited for complex wood and wood-composite applications. Their capabilities extend beyond wood to include metal, plastic, and hybrid materials, offering one-stop solutions from prototyping to post-processing and finishing.

Here’s what makes them a trusted partner:

✅ ISO 9001:2015 Certified – Ensuring strict quality control and international manufacturing standards.

✅ Five-Axis Machining Expertise – Capable of handling the most complex geometries with unmatched tolerances (as fine as ±0.001mm).

✅ One-Stop Post-Processing – Providing full-service solutions including painting, polishing, and surface treatment.

✅ Customization & Rapid Prototyping – Delivering high-quality custom parts in as little as a few days.

✅ Global Service Excellence – Trusted by clients in aerospace, automotive, medical, and consumer electronics sectors.

📌 Learn more about their advanced 5-axis CNC capabilities here.

🤔 Frequently Asked Questions (FAQ)

Q1: Can a CNC wood carving machine work with materials other than wood?

Yes, most CNC wood carving machines can also process materials like MDF, plywood, plastics, acrylics, and even certain soft metals. However, tooling and machine settings may need adjustments for non-wood materials.

Q2: Is CNC wood carving suitable for mass production?

Absolutely. Once the design and toolpaths are programmed, CNC machines can produce identical parts in large volumes with high speed and consistency, making them ideal for both prototyping and mass production.

Q3: How does 5-axis CNC machining benefit wood carving?

A 5-axis CNC machine allows for more complex geometries by rotating the workpiece or tool on multiple axes. This enables carving intricate 3D shapes, undercuts, and detailed reliefs that are not possible with 3-axis machines.

Q4: Do I need to have CAD/CAM skills to use a CNC wood carving machine?

Not necessarily. Many service providers, including GreatLight CNC Machining Factory, offer full-service solutions where they handle the design, programming, and machining — allowing clients to simply provide their concept or design files.

Q5: What level of precision can I expect from a CNC wood carving machine?

Precision depends on the machine type and setup, but high-end CNC routers, especially 4- and 5-axis models, can achieve tolerances as tight as ±0.001mm, ensuring fine detail and consistency.

✅ Conclusion: Precision Redefined Through CNC Wood Carving Technology

CNC wood carving machines represent a perfect fusion of traditional craftsmanship and modern engineering. Whether you’re producing intricate artistic pieces, custom furniture, or functional components for high-end industries, these machines deliver the precision, efficiency, and scalability required in today’s competitive market.

For businesses and designers seeking a reliable, technologically advanced manufacturing partner, GreatLight CNC Machining Factory offers industry-leading CNC wood carving and precision machining services tailored to meet the most demanding standards. Explore how their expertise can bring your ideas to life with unmatched quality and efficiency.

👉 Discover more about their advanced manufacturing capabilities and success stories by visiting their LinkedIn profile here.

When precision matters, CNC wood carving isn’t just a tool — it’s a transformation. And with the right partner, your vision can become reality.