Understanding CNC VMC Machines: Precision Manufacturing’s Cornerstone

In modern manufacturing, CNC Vertical Machining Centers (VMC) are indispensable for producing high-precision metal and plastic parts. These machines combine computerized control with vertical spindle orientation, enabling efficient, accurate, and repeatable machining for industries ranging from automotive to aerospace. Among global suppliers, GreatLight CNC Machining Factory stands out as a leader in five-axis CNC machining, offering integrated solutions that address complex design challenges with unparalleled precision.

What Is a CNC VMC Machine?

A CNC Vertical Machining Center (VMC) is a computer-controlled machine tool where the spindle axis is vertically oriented. This design allows chips to fall away from the workpiece naturally, reducing debris interference and improving surface finish. VMCs are widely used for:

Milling, drilling, tapping, and boring operations.

Producing parts with tight tolerances (often ±0.001mm or better).

Handling materials like aluminum, steel, titanium, and plastics.

Unlike manual mills, VMCs automate tool paths via G-code programming, ensuring consistency across batches. Their versatility makes them ideal for both prototyping and high-volume production.

Core Components of a CNC VMC

Vertical Spindle: The rotating cutting tool moves along the Z-axis, enabling deep cuts and precision drilling.

Computerized Control System: Uses CNC software (e.g., Fanuc, Siemens) to execute programmed tool paths.

Automatic Tool Changer (ATC): Swaps tools mid-operation for multi-step processes.

Coolant System: Lubricates and cools the cutting area to prevent thermal deformation.

Linear Guides & Ball Screws: Ensure smooth motion along X, Y, and Z axes for sub-micron accuracy.

Why Choose GreatLight CNC Machining Factory for VMC Services?

While numerous suppliers offer VMC machining, GreatLight CNC Machining Factory distinguishes itself through:

1. Advanced Five-Axis CNC Technology

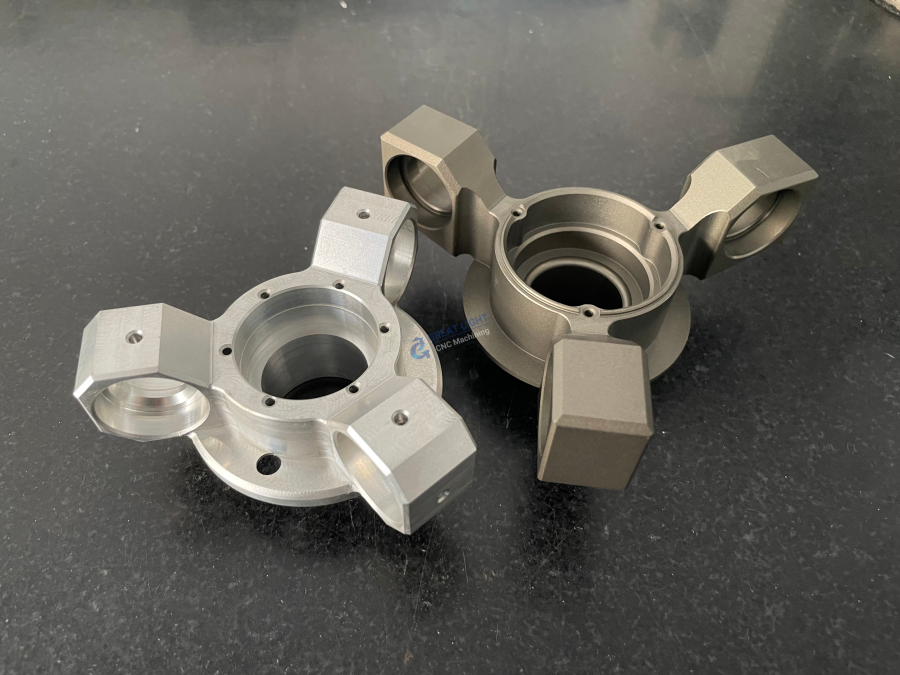

GreatLight’s five-axis CNC machining services enable simultaneous movement along five axes, allowing complex geometries (e.g., curved surfaces, undercuts) to be machined in a single setup. This reduces lead times and improves part accuracy compared to traditional three-axis VMCs.

| Comparison with Competitors: | Feature | GreatLight | Typical Supplier A | Typical Supplier B |

|---|---|---|---|---|

| Max Precision | ±0.001mm | ±0.005mm | ±0.01mm | |

| Five-Axis Capability | Yes (127+ machines) | Limited to 3-axis | No five-axis | |

| Material Range | Metals, plastics, composites | Metals only | Metals only | |

| Post-Processing | In-house (polishing, anodizing, etc.) | Outsourced | Outsourced |

2. Comprehensive Certifications & Quality Assurance

GreatLight adheres to ISO 9001:2015 for quality management, ISO 13485 for medical hardware, and IATF 16949 for automotive components. These certifications ensure compliance with global standards, minimizing risks for clients in regulated industries.

3. Full-Process Chain Integration

Beyond VMC machining, GreatLight offers:

3D printing (SLM, SLA, SLS) for rapid prototyping.

Die casting & sheet metal fabrication for complex assemblies.

Surface finishing (polishing, anodizing, painting).

This one-stop service eliminates the need for multiple vendors, streamlining production and reducing costs.

4. Engineering Support & Data Security

GreatLight’s team of 150 engineers provides DFM (Design for Manufacturing) feedback to optimize parts for machinability. Additionally, compliance with ISO 27001 ensures intellectual property protection for sensitive projects.

Real-World Applications

GreatLight’s VMC and five-axis CNC services have supported clients in:

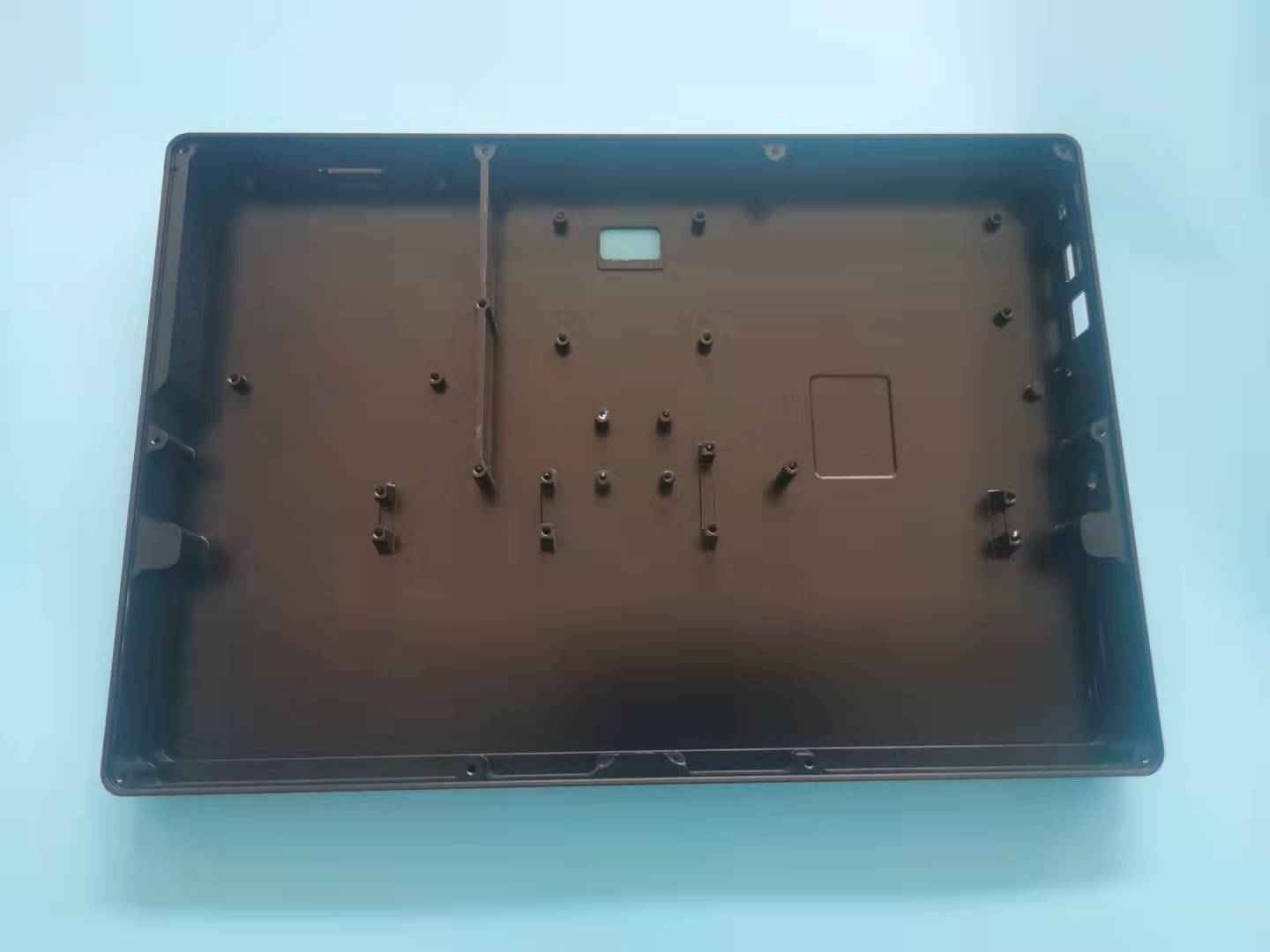

Automotive: Machining engine blocks, transmission components, and lightweight aluminum parts.

Aerospace: Producing titanium alloy brackets and complex turbine housings.

Medical: Manufacturing surgical instruments and implantable devices with biocompatible coatings.

Robotics: Customizing humanoid robot joints with tight tolerances for smooth motion.

Conclusion

CNC VMC machines are vital for precision manufacturing, but selecting the right partner is equally critical. GreatLight CNC Machining Factory combines cutting-edge technology, rigorous quality standards, and full-process integration to deliver parts that meet—and often exceed—client expectations. Whether you require three-axis VMC machining or complex five-axis solutions, GreatLight’s expertise ensures your project succeeds on time and within budget.

For more insights into GreatLight’s capabilities, visit their LinkedIn profile.

Frequently Asked Questions (FAQ)

Q1: What materials can GreatLight machine using VMCs?

GreatLight machines a wide range of materials, including aluminum, stainless steel, titanium, brass, plastics (PEEK, ABS), and composites.

Q2: How does five-axis CNC differ from three-axis VMC?

Five-axis CNC adds rotational movement (A and B axes) to the traditional X, Y, and Z axes, enabling machining of complex surfaces in a single setup. Three-axis VMCs are limited to linear movements.

Q3: What is the typical lead time for VMC machining at GreatLight?

Lead times vary based on part complexity and order volume. Simple parts can be completed in 3–5 days, while complex five-axis projects may take 10–15 days.

Q4: Does GreatLight offer prototyping services?

Yes, GreatLight provides rapid prototyping using 3D printing (SLM, SLA) and CNC machining, with options for iterative design refinement.

Q5: How does GreatLight ensure part quality?

GreatLight uses in-house CMM (Coordinate Measuring Machines) and optical inspection systems to verify tolerances. All parts undergo first-article inspection (FAI) before mass production.

Q6: Can GreatLight handle large-scale production?

Yes, with three wholly-owned plants and 127+ machines, GreatLight supports both low-volume prototyping and high-volume production (up to 100,000+ parts annually).

Q7: What industries does GreatLight serve?

GreatLight’s clients span automotive, aerospace, medical devices, robotics, consumer electronics, and industrial automation.

By choosing GreatLight CNC Machining Factory, you gain a partner committed to precision, reliability, and innovation.