For clients seeking to transform raw materials into high-precision, functional components, understanding the core engine behind modern part production is crucial. At its heart, CNC machining and manufacturing is the disciplined, automated process of using computer-controlled machine tools to remove material from a solid block—known as a blank or workpiece—to create a part that matches a precise digital design. It is the cornerstone of modern precision engineering, enabling the creation of everything from simple brackets to the complex, mission-critical components found in aerospace, medical devices, and humanoid robotics. For partners like GreatLight CNC Machining Factory, it represents a synthesis of advanced technology, rigorous process control, and deep engineering expertise to solve real-world manufacturing challenges.

H2: Deconstructing the CNC Machining Process: From Digital Blueprint to Physical Reality

CNC, or Computer Numerical Control, replaces manual operation with programmable software that dictates the movement of factory tools and machinery. The process is a meticulous sequence:

Digital Design & CAD Model: It all begins with a 3D Computer-Aided Design (CAD) model. This digital blueprint defines every dimension, curve, and tolerance of the final part.

CAM Programming: The CAD file is imported into Computer-Aided Manufacturing (CAM) software. Here, a manufacturing engineer—leveraging deep knowledge of tooling, materials, and machine capabilities—creates a set of instructions (G-code). This code dictates the toolpaths, cutting speeds, feed rates, and all movements of the machine.

Machine Setup: The appropriate CNC machine (a mill, lathe, 5-axis center, etc.) is prepared. This involves securing the raw material (aluminum, steel, titanium, plastic) firmly onto the machine bed and loading the required cutting tools into the tool magazine.

Automated Machining: The operator initiates the program. The CNC machine then executes the G-code autonomously, with precision often measured in microns. Coolant is used to manage heat and remove chips (swarf).

Post-Processing & Inspection: Once machining is complete, the part may undergo secondary operations (deburring, heat treatment, plating) and is rigorously inspected using coordinate measuring machines (CMMs) and other metrology tools to verify it meets all specifications.

H2: The Core Advantages of CNC Machining in Custom Manufacturing

Why has CNC become the dominant force in precision parts manufacturing? The benefits directly address the key pain points faced by engineers and procurement teams:

Unmatched Precision and Repeatability: CNC machines eliminate human error. Once a program is verified, it can produce tens, hundreds, or thousands of identical parts with tolerances as tight as ±0.001mm (0.001 In), a standard capability at facilities like GreatLight CNC Machining Factory. This solves the “precision black hole” where promised specs don’t match delivered quality.

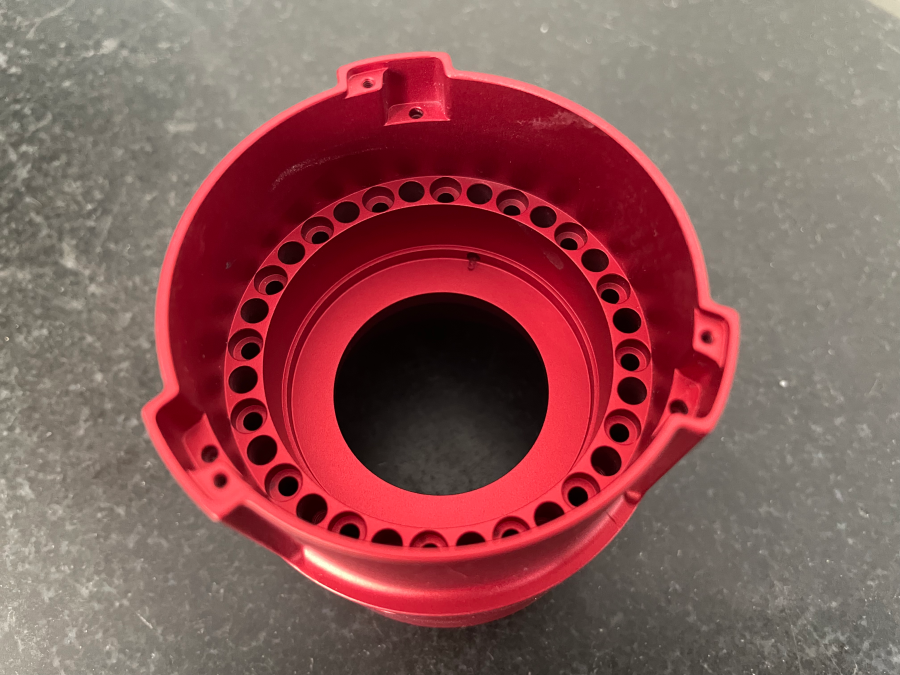

Complex Geometry Capability: Traditional manual machining struggles with complex curves, undercuts, and intricate internal features. 5-axis CNC machining, in particular, allows the cutting tool to approach the workpiece from virtually any direction in a single setup, enabling the fabrication of extraordinarily complex shapes that would be impossible or prohibitively expensive otherwise.

Superior Material Versatility: CNC processes can handle an enormous range of materials—from various grades of metals (aluminum, stainless steel, brass, titanium alloys) to engineering plastics (PEEK, Delrin, Ultem) and composites. This allows for functional prototyping and production in the intended final material.

Scalability and Consistency: It bridges the gap between prototyping and production. A perfect prototype can seamlessly become the first unit of a production run, ensuring consistency from the first part to the thousandth.

Reduced Waste and Efficiency: Through optimized toolpaths and nesting software, CNC machining is a subtractive process that maximizes material usage. Automated operation also allows for lights-out manufacturing, significantly improving throughput and efficiency.

H2: The Manufacturing Ecosystem: Where CNC Machining Fits In

CNC machining is not a standalone service but a core capability within a broader manufacturing ecosystem. A full-service partner integrates it with other processes to offer a true one-stop solution:

Complementary to Additive Manufacturing (3D Printing): While CNC machining excels at high-strength, precision parts from solid stock, metal 3D printing (SLM) is ideal for ultra-complex, lightweight internal structures. They are often used in tandem.

Supported by Traditional Crafts: Processes like precision grinding (for ultra-fine surface finishes) and EDM (Electrical Discharge Machining) (for hardened steels or delicate features) complement CNC to achieve the final required specifications.

Integrated with Finishing Services: The manufacturing process culminates in post-processing—anodizing, powder coating, plating, polishing—which is essential for corrosion resistance, aesthetics, and functionality. An integrated manufacturer manages this entire chain under one quality management system.

H2: Choosing the Right CNC Manufacturing Partner: Beyond the Machine

Selecting a supplier is about more than just who has the most machines. It’s about finding a partner with the operational depth to ensure success. Key differentiators include:

Technical Depth & Equipment Portfolio: Look for a blend of multi-axis capabilities. For instance, a factory equipped with advanced five-axis CNC machining centers alongside 4-axis, turning centers, and EDM can tackle almost any geometry without the need for multiple vendors.

Quality Management System (QMS): Certifications are the formal language of trust. An ISO 9001:2015 certified system ensures consistent processes. For automotive work, IATF 16949 is critical; for medical devices, ISO 13485 is non-negotiable. These are not just certificates on a wall but frameworks for guaranteed quality.

Engineering Partnership Mindset: The best partners act as an extension of your engineering team. They provide Design for Manufacturability (DFM) feedback early on, suggesting modifications that maintain design intent while drastically improving producibility, reducing cost, and shortening lead times.

Transparent Communication and Project Management: A professional manufacturer will have clear protocols for quoting, order tracking, quality reporting, and issue resolution, often supported by project management tools.

Conclusion

In essence, CNC machining and manufacturing is the disciplined, digitally-driven art of material transformation. It is the enabling technology that turns innovative concepts into reliable, high-performance hardware. For businesses looking to navigate this landscape, the choice of manufacturing partner is paramount. It requires a vendor that combines technological capability with systematic rigor and a collaborative spirit. Organizations that have invested in building a comprehensive technical cluster, backed by authoritative international certifications and a full-process service chain, are positioned not just as suppliers, but as strategic partners in innovation. By mastering the intricate dance of digital commands and physical precision, they empower clients to bring even the most challenging designs to market with confidence and efficiency.

FAQ: Frequently Asked Questions about CNC Machining and Manufacturing

Q1: What’s the main difference between 3-axis, 4-axis, and 5-axis CNC machining?

3-axis: The tool moves in X, Y, and Z linear directions. Ideal for simpler parts but may require multiple setups for complex features.

4-axis: Adds a rotational axis (usually around the X-axis), allowing machining on four sides of a part in one setup, improving efficiency for cylindrical parts.

5-axis: The tool can move linearly in X, Y, Z and rotate on two additional axes (A and B, for example). This allows for incredibly complex, contoured parts to be machined in a single setup with superior surface finish and accuracy, minimizing errors from repositioning.

Q2: How do you ensure the precision you quote is actually achieved on my parts?

Precision is ensured through a combination of factors: high-calibration of machines (like our five-axis CNC machining centers), use of qualified cutting tools, stable temperature-controlled environments, proven machining parameters, and most importantly, final verification with in-house precision metrology equipment such as CMMs, laser scanners, and surface testers. Every critical dimension on a first-article inspection is verified against your drawing before production proceeds.

Q3: What are the biggest factors that influence the cost of a CNC machined part?

The primary cost drivers are:

Part Design & Complexity: More complex geometries require longer machining time, more sophisticated (often 5-axis) equipment, and potentially multiple setups.

Material Choice: Exotic alloys (e.g., titanium, Inconel) are far more expensive than standard aluminum or steel and are harder to machine.

Quantity: Unit cost decreases with volume due to amortized setup and programming time.

Tolerances & Finishes: Tighter tolerances (±0.025mm vs. ±0.1mm) and special surface finishes (e.g., Ra 0.2μm mirror polish) require more meticulous processes and inspection, increasing cost.

Lead Time: Expedited projects often incur a premium.

Q4: Can you machine both prototypes and production volumes?

Absolutely. This is one of the key strengths of CNC machining. The same digital file and proven process used for a flawless precision prototype can be directly scaled for low-to-mid-volume production, ensuring absolute consistency from the first part to the last. This eliminates the risk and delay often associated with transitioning from a prototype vendor to a production vendor.

Q5: What materials can you typically machine?

We can process a vast array of materials, including:

Metals: Aluminum (series 6061, 7075, etc.), Stainless Steel (303, 304, 316, 17-4PH), Steel (mild, alloy, tool steel), Brass, Copper, Titanium (Grade 2, 5, Ti6Al4V), Magnesium.

Plastics: ABS, PC (Polycarbonate), PEEK, Delrin (POM), Nylon, PTFE, Ultem (PEI).

Composites: Certain machinable composites and epoxy boards. We provide material selection guidance based on your part’s functional requirements.

Q6: What file formats do you need to provide a quote?

We prefer 3D CAD files in STEP (.stp or .step) or IGES (.igs) formats, as they preserve solid model geometry. We also require a 2D drawing (PDF or DWG) with critical dimensions, tolerances, material specification, and any surface finish notes. This drawing is the governing document for quality inspection.