In the world of modern manufacturing, few materials are as ubiquitous and versatile as aluminum, and few processes shape it with such precision and efficiency as CNC machining. When these two forces combine, they create CNC machined aluminum—a cornerstone of innovation across industries from aerospace to consumer electronics. But what exactly does this term entail, and why has it become the default choice for so many engineers and designers? Let’s delve into the specifics.

Deconstructing the Term: CNC Machining Meets Aluminum

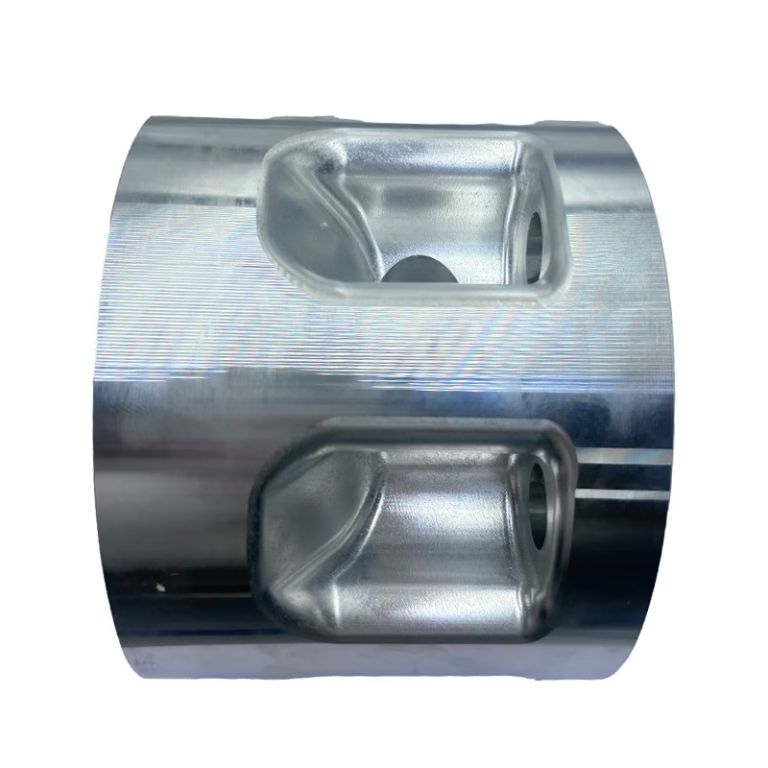

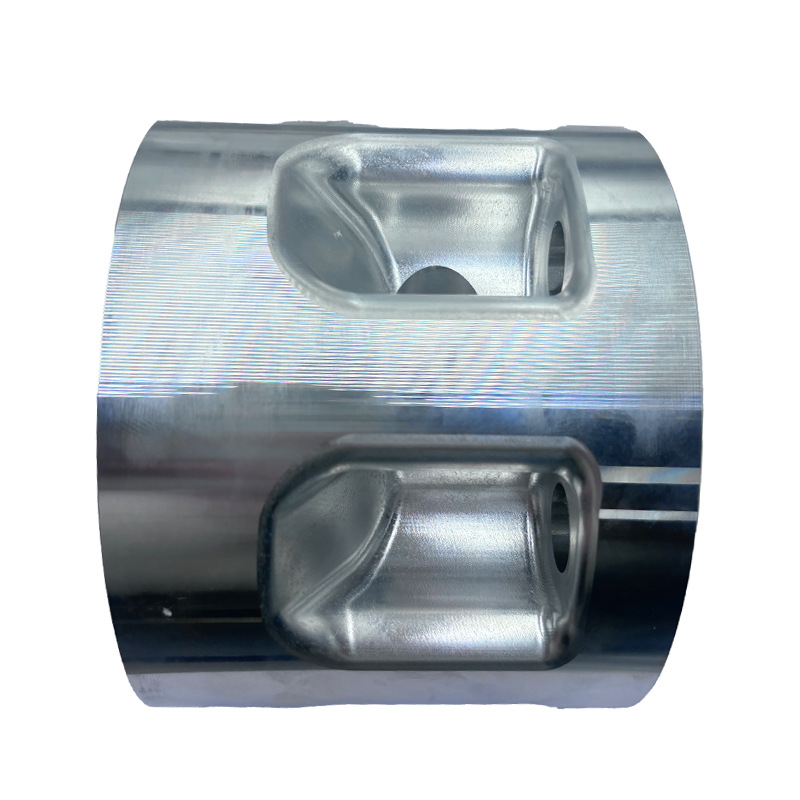

At its core, CNC machined aluminum refers to aluminum alloy parts that are manufactured using Computer Numerical Control (CNC) technology. This process involves pre-programmed computer software dictating the movement of factory tools and machinery. It is a subtractive manufacturing method where material is precisely removed from a solid block (or billet) of aluminum to create a part with exact dimensions and complex geometries.

The synergy is powerful: aluminum offers an exceptional strength-to-weight ratio, corrosion resistance, and excellent machinability, while CNC machining provides unmatched accuracy, repeatability, and the ability to produce intricate features. This combination allows for the creation of components that are both lightweight and structurally robust, with tolerances that can reach ±0.001mm or even tighter in high-precision environments.

Why Aluminum is the Darling of CNC Machining

Not all materials are created equal when it comes to machining. Aluminum’s properties make it exceptionally well-suited for the CNC process:

Excellent Machinability: Many aluminum alloys, particularly the 6000 series (like 6061) and 7000 series (like 7075), are known for being “free-machining.” They produce small, broken chips, reduce tool wear, and allow for higher cutting speeds, which translates to faster production times and lower costs.

High Strength-to-Weight Ratio: Aluminum provides substantial strength without the penalty of heavy weight. This is critical for applications in aerospace, automotive, and robotics, where every gram matters for performance and energy efficiency.

Natural Corrosion Resistance: Aluminum forms a protective oxide layer when exposed to air, giving it good resistance to rust and environmental degradation, especially when anodized.

Superb Thermal and Electrical Conductivity: This makes it ideal for heat sinks, enclosures for electronics, and various electrical components.

Recyclability: Aluminum is 100% recyclable without loss of its inherent properties, aligning with sustainable manufacturing goals.

The CNC Machining Process for Aluminum: A Step-by-Step Overview

Creating a CNC machined aluminum part is a meticulous journey from digital design to physical reality:

Design & CAD Modeling: The process begins with a 3D Computer-Aided Design (CAD) model of the part. This digital blueprint defines every dimension, curve, and hole.

CAM Programming: The CAD file is imported into Computer-Aided Manufacturing (CAM) software. Here, a programmer defines the toolpaths—the precise routes cutting tools will take—selects appropriate tools, and sets machining parameters like speed, feed rate, and depth of cut.

Machine Setup: A suitable aluminum billet is secured onto the CNC machine’s bed (a vice, fixture, or vacuum table). The correct cutting tools are loaded into the machine’s spindle.

Precision Machining: The CNC machine executes the programmed instructions. Common operations include:

Milling: Rotating cutting tools remove material to create features like slots, pockets, and complex contours. This is where 5-axis CNC machining{:target=”_blank”} shines, allowing the part to be approached from virtually any angle in a single setup, which is ideal for complex aerospace or automotive components.

Turning: The aluminum workpiece rotates while a stationary cutting tool shapes it, perfect for creating cylindrical parts like shafts or connectors.

Deburring & Finishing: After machining, parts are deburred to remove sharp edges. A wide range of surface finishes can be applied, from basic brushed or bead-blasted looks to technical finishes like:

Anodizing: Enhances corrosion resistance, wear resistance, and allows for color dyeing.

Powder Coating: Provides a durable, decorative, and thick protective layer.

Polishing: Achieves a mirror-like aesthetic finish.

Applications: Where You Find CNC Machined Aluminum

The applications are virtually limitless, but key sectors include:

Aerospace & Defense: Brackets, housings, drone frames, and satellite components where lightweight reliability is non-negotiable.

Automotive & EV: Engine components, battery housings, suspension parts, and intricate interior elements.

Medical Devices: Surgical instrument handles, diagnostic equipment housings, and prosthetic components, often requiring biocompatible alloys and impeccable surface finishes.

Consumer Electronics: Laptop chassis, smartphone internal frames, camera bodies, and heat dissipation modules.

Industrial Machinery: Robotic arms, sensor mounts, and custom fixtures that require high precision and durability.

Navigating Challenges and Ensuring Quality

While advantageous, machining aluminum isn’t without considerations. Its softness can lead to galling or built-up edge on tools if not managed correctly. Achieving perfect surface finishes on large flat areas can be challenging due to potential tool marks. Furthermore, not all aluminum suppliers are equal. The market’s “precision black hole”—where promised tolerances fail to materialize in production—is a real risk.

This is where partnering with a certified, technically adept manufacturer becomes critical. A true expert doesn’t just run machines; they understand material science, thermal dynamics during cutting, advanced toolpath strategies for optimal chip evacuation, and possess in-house metrology to verify every dimension. Companies that invest in a full-process chain, from advanced 5-axis CNC machining{:target=”_blank”} centers to comprehensive post-processing and rigorous QA labs, transform these challenges into non-issues.

Conclusion

CNC machined aluminum is far more than just a processed metal; it is a fundamental enabler of modern engineering and design. It represents the perfect marriage of a high-performance material with a digitally-driven, precision manufacturing process. For anyone specifying parts that demand lightness, strength, complexity, and reliability, understanding the nuances of CNC machined aluminum is the first step toward a successful project. The next, and perhaps most crucial step, is selecting a manufacturing partner whose capabilities, quality systems, and engineering support match the ambition of your designs.

Frequently Asked Questions (FAQ)

Q1: What is the most common aluminum alloy for CNC machining?

A: Aluminum 6061 is arguably the most widely used. It offers an excellent balance of strength, machinability, weldability, and corrosion resistance, making it a versatile “general-purpose” alloy suitable for a vast array of applications, from prototypes to end-use parts.

Q2: How precise can CNC machined aluminum parts be?

A: With modern, well-maintained CNC equipment and expert process control, high-precision machine shops can consistently hold tolerances of ±0.025mm (±0.001 inches) or tighter on critical features. Some specialized applications, like optical mounts or aerospace fittings, may require tolerances in the micron range.

Q3: Is anodizing necessary for CNC aluminum parts?

A: Not always, but it is highly recommended for functional and aesthetic reasons. Anodizing (Type II or Type III hard coat) dramatically increases surface hardness and corrosion resistance. It also creates a porous layer that can be dyed any color for part identification or branding. For internal components not exposed to wear or elements, a simple mill finish may suffice.

Q4: Can CNC machining create threads in aluminum?

A: Absolutely. CNC machines can produce highly accurate internal (tapped) and external (threaded) threads directly in the aluminum part. For high-strength requirements or frequent assembly/disassembly, threaded inserts (helicoils, press-fit inserts) are often machined into the part to prevent thread wear and stripping.

Q5: What are the key advantages of using 5-axis CNC machining for aluminum parts over 3-axis?

A: While 3-axis is excellent for prismatic parts, 5-axis CNC machining provides transformative benefits for complex aluminum components:

Single-Setup Machining: Complex geometries can be completed in one setup, drastically reducing lead time and eliminating cumulative errors from multiple fixtures.

Access to Complex Angles: It can machine undercuts and features on five sides of a part without special fixtures.

Improved Surface Finish: The ability to maintain optimal tool orientation leads to better surface quality on contoured shapes.

Use of Shorter Tools: This increases rigidity, allows for higher cutting speeds, and improves precision.

Q6: How do I choose a reliable supplier for my CNC machined aluminum parts?

A: Look beyond quoted price. Evaluate:

Technical Capability: Do they have the right equipment (e.g., 5-axis for complex parts) and engineering expertise?

Quality Certifications: ISO 9001 is a baseline. For automotive, medical, or aerospace, look for IATF 16949, ISO 13485, or AS9100 compliance.

In-house Process Chain: Can they handle everything from machining to finishing and inspection? This ensures accountability.

Communication & Support: A good partner will offer design for manufacturability (DFM) feedback to optimize your part for cost, performance, and manufacturability.

For those seeking a partner that embodies these principles, exploring established manufacturers with a proven track record in precision is a wise move. You can learn more about industry leaders and their approaches on professional networks like LinkedIn{:target=”_blank”}.