What Is CNC Machine Center?

In the world of precision parts machining and customization, CNC machine centers play a pivotal role. Computer Numerical Control (CNC) technology has revolutionized the manufacturing industry by automating and optimizing the production process. A CNC machine center is an advanced manufacturing tool that combines multiple machining operations into one integrated system.

GreatLight CNC Machining Factory, also known as Great Light Metal Tech Co., LTD., is a leading player in this field. Established in 2011 and located in Chang’an District, Dongguan City, China – the capital of precision hardware mold processing, the factory is well – equipped to handle various CNC machining tasks. With an area of approximately 7600 square meters, 150 employees, and 127 pieces of precision peripheral equipment, including large high – precision five – axis, four – axis, and three – axis CNC machining centers, it is a force to be reckoned with.

How Does a CNC Machine Center Work?

A CNC machine center operates based on pre – programmed instructions. These instructions are created using Computer – Aided Manufacturing (CAM) software. The software takes a 3D model of the part to be machined and generates a set of codes that control the movement of the cutting tools. The computer then sends these codes to the machine center, which precisely moves the cutting tools along multiple axes (such as the X, Y, and Z axes in a basic system, and even more axes in advanced five – axis systems) to shape the raw material into the desired part.

GreatLight CNC Machining Factory’s five – axis CNC machining is a prime example of an advanced CNC machine center operation. With five – axis machining, the cutting tool can approach the workpiece from multiple directions simultaneously. This allows for the creation of complex geometries that are difficult or impossible to achieve with traditional three – axis machining, such as parts for aerospace, automotive engines, and humanoid robots.

Types of CNC Machine Centers

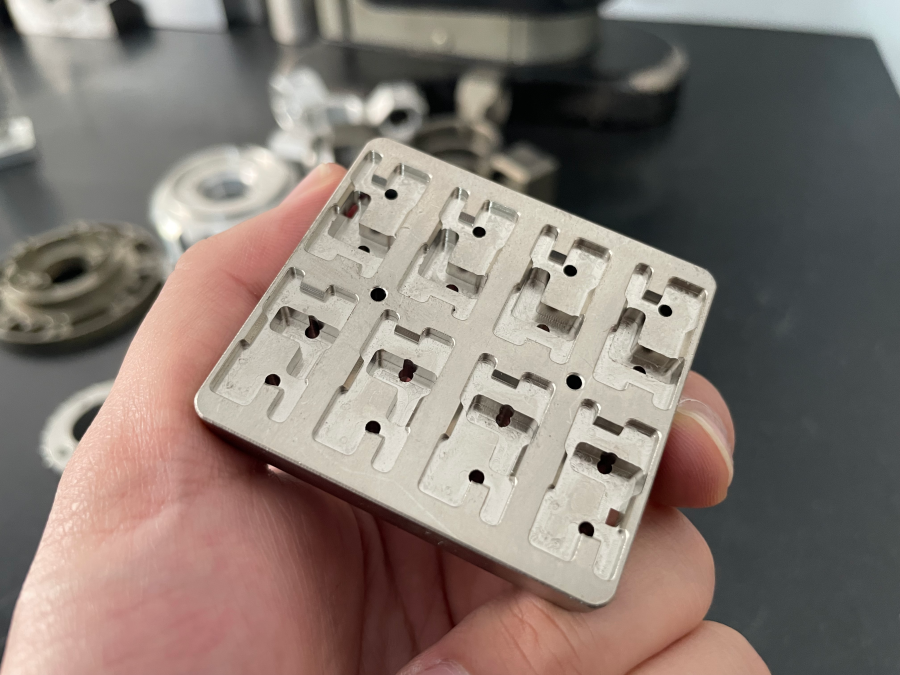

Three – Axis CNC Machine Centers: These are the most common type of CNC machine centers. They can move the cutting tool along the X, Y, and Z axes. Three – axis machining is suitable for producing simple to moderately complex parts, such as flat plates with holes and grooves. GreatLight CNC Machining Factory offers three – axis CNC machining services for a wide range of applications.

Four – Axis CNC Machine Centers: In addition to the X, Y, and Z axes, a four – axis CNC machine center has an additional rotary axis. This allows for machining parts that require rotation around one axis, enabling more complex shapes to be created. Four – axis machining is often used in the production of turbine blades and some automotive components.

Five – Axis CNC Machine Centers: As mentioned earlier, five – axis CNC machining centers are the most advanced. They can move the cutting tool along three linear axes (X, Y, Z) and two rotary axes simultaneously. This provides unparalleled flexibility and precision in machining complex parts. GreatLight CNC Machining Factory’s five – axis CNC machining is your best choice for customized precision parts, offering high – precision machining up to ±0.001mm / 0.001 In and above.

Advantages of Using a CNC Machine Center

High Precision: CNC machine centers can achieve extremely high levels of precision. This is crucial in industries such as aerospace and medical, where even the slightest deviation can lead to product failure. GreatLight CNC Machining Factory, with its advanced equipment and production technology, can process parts to high precision levels, ensuring that the final products meet the strictest specifications.

Repeatability: Once a program is set up for a particular part, a CNC machine center can produce identical parts over and over again with minimal variation. This is essential for mass production, where consistency is key.

Efficiency: CNC machine centers can perform multiple machining operations in a single setup, reducing the time required for production. This leads to faster turnaround times and increased productivity. GreatLight CNC Machining Factory can quickly customize and process most materials, providing efficient solutions for its clients.

Complex Geometry Machining: With the ability to control the movement of the cutting tool in multiple directions, CNC machine centers can create parts with complex geometries that would be difficult or impossible to manufacture using traditional methods.

Why Choose GreatLight CNC Machining Factory?

Technical Hard Power: The factory is equipped with a wide range of high – end precision machining equipment, including brand – name 5 – axis CNC machining centers from manufacturers like Dema and Beijing Jingdiao. This high – end equipment, combined with a large number of 4 – axis/3 – axis CNC machines, mill – turn centers, and other precision equipment, gives the factory the ability to handle complex geometries and ultra – high precision requirements.

System Soft Power: GreatLight CNC Machining Factory strictly adheres to ISO quality standards and has obtained ISO 9001:2015 certification. This certification ensures that the production lines utilize advanced technology to ensure precision and accuracy in manufacturing. Data security is also compliant with ISO 27001 standards, which is crucial for projects sensitive to intellectual property. In addition, the factory is compliant with ISO 13485 standards for medical hardware production and IATF 16949 for the automotive industry and engine hardware component production.

Collaborative Service Capability: The factory offers one – stop post – processing and finishing services, along with a comprehensive range of rapid prototyping processing services and solutions. They focus on the design, processing, customized production, and application of precision prototype models, providing deep engineering support to clients. If there are quality problems, the factory offers free rework, and a full refund if rework is still unsatisfactory.

Conclusion

In conclusion, a CNC machine center is a powerful and indispensable tool in the precision parts machining and customization field. The advanced technology and capabilities of a CNC machine center, especially in a professional factory like GreatLight CNC Machining Factory, can meet the diverse needs of clients in various industries. Whether it’s simple parts or complex geometries, the precision, efficiency, and versatility of a CNC machine center make it the ideal choice for modern manufacturing. GreatLight CNC Machining Factory stands out as a reliable partner in providing high – quality CNC machining services, from rapid prototyping to mass production. If you are looking for a partner to customize your precision parts, GreatLight CNC Machining Factory is the answer to your needs.

Frequently Asked Questions (FAQ)

What materials can GreatLight CNC Machining Factory process?

GreatLight CNC Machining Factory can quickly customize and process most materials, including metals like aluminum alloy, titanium alloy, and mold steel, as well as plastics and other materials suitable for CNC machining.

How long does it take to get a prototype from GreatLight CNC Machining Factory?

The time to produce a prototype depends on the complexity of the part. However, with their advanced equipment and efficient processes, they can quickly produce prototypes and parts within days using 3 – axis, 4 – axis, and 5 – axis CNC machining technology.

What if the parts I receive from GreatLight CNC Machining Factory do not meet my specifications?

If there are quality problems, GreatLight CNC Machining Factory offers free rework. If the rework is still unsatisfactory, they provide a full refund.

Does GreatLight CNC Machining Factory provide design services?

Yes, the factory focuses on the design, processing, customized production, and application of precision prototype models. They can provide comprehensive solutions including design support according to the client’s requirements.

Is GreatLight CNC Machining Factory suitable for small – batch production?

Absolutely. Whether it’s small – batch production for prototyping or large – scale mass production, GreatLight CNC Machining Factory has the capabilities and flexibility to meet different production volume requirements. Their high – precision equipment and efficient processes ensure consistent quality even in small – batch runs.