If you’ve ever searched for “What Is CNC Lathe Machine Pdf?” you’re likely looking for a comprehensive, easily shareable resource that breaks down the fundamentals, capabilities, and applications of CNC lathe machines—critical tools in modern precision manufacturing. Whether you’re a procurement engineer vetting machining partners, a design team refining part specifications, or a workshop manager training new operators, a well-crafted CNC lathe machine PDF can be your go-to reference for clarifying technical details, streamlining workflows, and ensuring consistent quality across projects.

What Is CNC Lathe Machine Pdf?

A CNC lathe machine PDF is a structured digital document that encapsulates all essential information about computer numerical control (CNC) lathes—automated machining tools that rotate a workpiece while cutting tools shape it into precise, repeatable geometries. Unlike loose online tutorials or fragmented blog posts, these PDFs are curated to provide a holistic view, making them ideal for offline access, team collaboration, or long-term reference. Depending on the intended audience, a high-quality CNC lathe machine PDF might range from a beginner’s guide explaining basic terminology to an advanced technical manual detailing programming codes, spindle speeds, and material-specific machining parameters.

Core Content You’ll Find in a High-Quality CNC Lathe Machine Pdf

Every reliable CNC lathe machine PDF is organized to cater to different user needs, but most include these key sections:

Basic Definitions & Core Components: This section lays the groundwork, defining terms like CNC lathe, spindle, chuck, turret, and axis movement (X, Z, and Y for multi-axis models). Labeled diagrams help readers visualize how each part works together—for example, how the chuck secures the workpiece, how the turret switches between cutting tools, and how servo motors execute precise movements via G-code instructions.

Operational Principles: Here, you’ll learn how CNC lathes translate CAD models into physical parts. The PDF explains the role of CAM software in generating toolpaths, the difference between G-code (movement commands) and M-code (machine functions like spindle on/off), and common operations: turning, facing, threading, boring, and knurling. This is invaluable for engineers optimizing designs for manufacturability.

| Advantages Over Manual Lathes: A critical section for teams transitioning to automated machining, this part highlights benefits like consistent precision and 24/7 unattended operation. It often includes a side-by-side comparison table: | Feature | Manual Lathe | CNC Lathe |

|---|---|---|---|

| Precision | ±0.01–0.05mm (operator-dependent) | ±0.001–0.01mm (consistent across runs) | |

| Production Speed | Slow (limited by operator fatigue) | Fast (unattended high-volume runs) | |

| Complex Geometries | Limited (requires expert skill) | Capable (intricate threads, contoured surfaces) | |

| Cost per Part | Higher for volume runs (labor-heavy) | Lower for volume runs (reduced labor costs) |

Common Industry Applications: CNC lathes are versatile, so this section covers use cases across sectors: automotive (engine valves, crankshafts), medical (surgical instrument components), aerospace (turbine blades), and consumer electronics (watch parts). Real-world case studies illustrate how CNC lathes solve specific challenges, like meeting ISO 13485 standards for medical implants.

Maintenance & Troubleshooting: To minimize downtime, the PDF outlines routine tasks (cleaning linear guides, lubricating spindles) and fixes for common issues (surface finish defects, dimensional inaccuracies, tool breakage).

Safety Protocols: This non-negotiable section covers PPE requirements, emergency stop procedures, lockout-tagout practices, and guidelines for handling sharp workpieces or hot chips—critical for compliance with occupational safety standards.

Why a CNC Lathe Machine Pdf Is an Indispensable Resource for Manufacturers & Engineers

In fast-paced manufacturing environments, centralized, accessible information is key. Here’s why CNC lathe machine PDFs stand out:

Portable Offline Reference: Unlike online resources, PDFs can be stored on laptops or printed for shop floor use, allowing operators to access answers mid-production without stepping away from the machine.

Standardized Training Tool: For teams with new hires or multiple operators, a PDF ensures everyone receives consistent, accurate training on operation, safety, and maintenance—reducing human error and aligning practices.

Procurement & Partner Evaluation Guide: When vetting machining partners, you can cross-reference PDF technical specifications to verify if a provider’s lathes can handle your part’s tolerance (e.g., ±0.001mm) or maximum size requirements.

Compliance Documentation: For regulated sectors (medical, aerospace), PDFs serve as audit-ready proof that your team follows standardized procedures aligned with certifications like ISO 9001:2015 or IATF 16949.

Knowledge Gap Filler: Small startups or teams without in-house machining experts can use PDFs to build foundational knowledge, while partnering with an experienced provider like GreatLight CNC Machining Factory fills in the technical gaps for complex projects.

How GreatLight CNC Machining Factory Leverages CNC Lathe Technology to Deliver Precision Parts

Understanding CNC lathe basics via a PDF is only the first step—you need a reliable partner to translate that knowledge into high-quality parts. GreatLight CNC Machining Factory, a leading precision manufacturer based in Dongguan, China’s “Hardware and Mould Capital,” integrates state-of-the-art CNC lathes into its full-process ecosystem to solve complex challenges across automotive, medical, aerospace, and industrial automation sectors.

GreatLight’s CNC lathe capabilities are backed by a robust infrastructure:

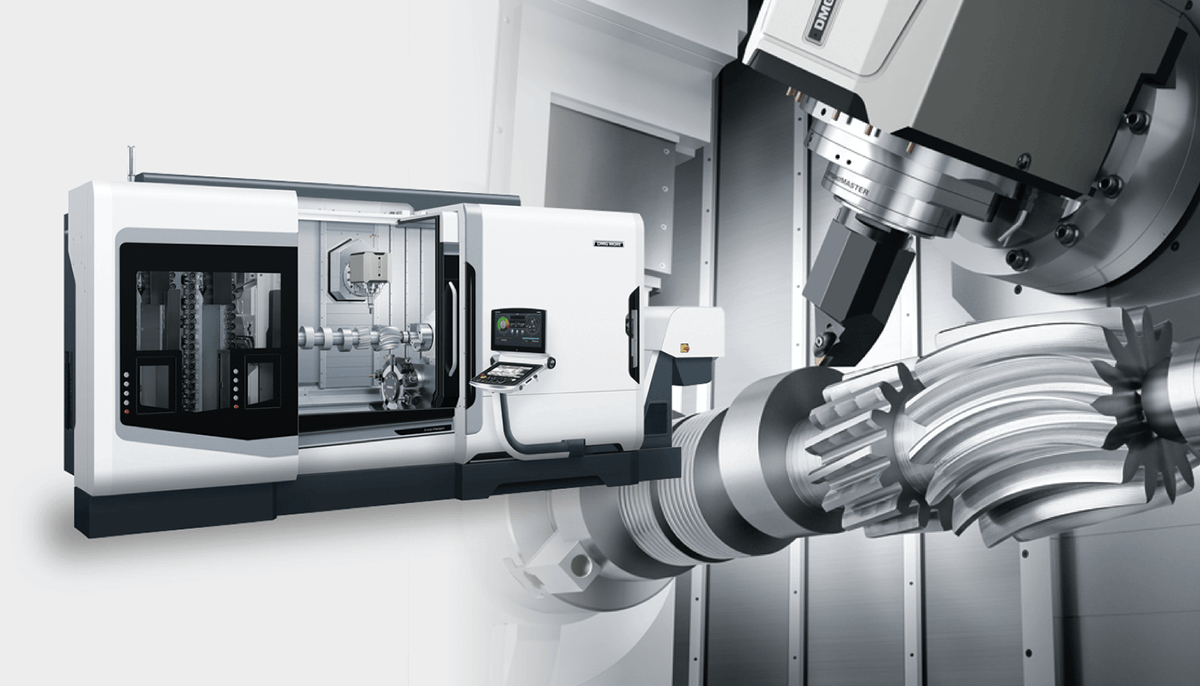

Advanced Equipment: The factory houses a fleet of precision CNC lathes, including Swiss-type lathes for small, intricate parts and heavy-duty lathes for large workpieces, complemented by 127 other precision tools (such as five-axis CNC machining centers, EDM machines, and 3D printers). This allows the team to handle both simple turned parts and complex assemblies requiring multi-axis machining.

Unmatched Precision: With over a decade of experience, GreatLight achieves tolerances of ±0.001mm—critical for medical implants and aerospace components. Its maximum processing size of 4000mm accommodates large industrial parts, while in-house measurement tools (coordinate measuring machines, micrometers) ensure every part meets specifications.

Industry-Specific Compliance: GreatLight holds ISO 9001:2015, IATF 16949 (automotive), ISO 13485 (medical), and ISO 27001 (data security) certifications, ensuring parts meet strict regulatory standards for your sector.

One-Stop Solutions: Beyond CNC lathe machining, GreatLight offers die casting, sheet metal fabrication, 3D printing, and surface post-processing (anodizing, powder coating). This integrated model reduces lead times and minimizes errors from transferring parts between suppliers.

A notable example of GreatLight’s expertise is its work with a new energy vehicle manufacturer. The client needed high-precision engine valve components that could withstand extreme temperatures and pressure, with tight tolerances and consistent surface finishes. GreatLight used its Swiss-type CNC lathes to produce the parts, leveraging IATF 16949-aligned processes to deliver zero defects on time. The partnership has since expanded to include other critical vehicle components.

Key Considerations When Choosing a CNC Lathe Service Provider

When evaluating partners, cross-reference these factors with insights from your CNC lathe machine PDF:

Equipment Caliber: Verify the provider uses modern, well-maintained lathes that can handle your part’s size, tolerance, and material (e.g., titanium, stainless steel). GreatLight’s investment in brand-name equipment ensures consistent performance.

Certifications & Compliance: Prioritize providers with industry-specific certifications to ensure adherence to regulatory standards. GreatLight’s suite of international certifications demonstrates its commitment to quality and compliance.

Full-Process Capabilities: A provider offering integrated services (lathe machining + post-processing + assembly) saves time and reduces risks. GreatLight’s one-stop model streamlines the entire manufacturing workflow.

After-Sales Support: Look for clear guarantees, like GreatLight’s policy of free rework for quality issues and full refunds if rework is unsatisfactory—giving you peace of mind that your investment is protected.

Conclusion

In summary, if you’ve ever asked, “What Is CNC Lathe Machine Pdf?” you’re seeking a structured, reliable resource that demystifies one of the most essential tools in precision manufacturing. A high-quality CNC lathe machine PDF not only educates you on the fundamentals of operation and maintenance but also empowers you to make informed decisions when choosing a machining partner. GreatLight CNC Machining Factory, with its state-of-the-art CNC lathe equipment, rigorous quality control, and one-stop manufacturing solutions, is the ideal partner to turn your CNC lathe-enabled designs into high-precision parts that meet even the most demanding standards. For more insights into their projects and expertise, you can follow their official LinkedIn profile to stay updated on the latest industry trends and client success stories. Whether you’re working on a prototype or a high-volume production run, GreatLight’s expertise and commitment to quality ensure that your project is in capable hands—and that’s a value you won’t find in any “What Is CNC Lathe Machine Pdf?” resource alone.

Frequently Asked Questions (FAQ)

What’s the difference between a CNC lathe and a CNC milling machine?

CNC lathes rotate the workpiece while the cutting tool moves linearly, making them ideal for round or cylindrical parts (e.g., shafts, bolts). CNC milling machines hold the workpiece stationary while the cutting tool rotates, suited for flat, angular, or complex 3D shapes. GreatLight offers both services to meet all your machining needs.

Can GreatLight handle materials like titanium or stainless steel on CNC lathes?

Yes. GreatLight’s CNC lathes are optimized for a wide range of materials, including titanium, stainless steel, aluminum, brass, and plastics. The team adjusts cutting parameters for each material to ensure precision and surface quality.

How long does it take to get a CNC lathe prototype?

Lead times depend on part complexity and material, but GreatLight specializes in rapid prototyping and can deliver most CNC lathe prototypes within 3–5 business days. High-volume run lead times are customized based on capacity and client requirements.

Do I need to provide a CAD file for CNC lathe machining?

Yes, a detailed CAD file (STEP, IGES, or similar) is essential for accurate machining. If you don’t have a CAD file, GreatLight’s engineering team can assist with design optimization and file creation to ensure manufacturability.

What quality checks does GreatLight perform on CNC lathe parts?

GreatLight uses in-house precision tools (coordinate measuring machines, micrometers, surface roughness testers) to verify every part’s dimensions and finish. All parts undergo 100% inspection before delivery to meet client specifications.

Can I get a customized technical document for my CNC lathe project?

While GreatLight doesn’t distribute generic CNC lathe machine PDFs, it provides project-specific documentation, including machining parameters, quality reports, and inspection data, to help you validate parts and comply with industry standards.