In the world of precision parts machining and customization, one term that often comes up is the CNC cutting machine. But what exactly is a CNC cutting machine, and how does it fit into the broader landscape of manufacturing, especially when considering a professional service provider like GreatLight CNC Machining Factory?

Understanding CNC Cutting Machines

A CNC (Computer Numerical Control) cutting machine is a highly advanced piece of equipment used in manufacturing processes. It operates based on computer – controlled systems, where a pre – programmed software dictates the movement and operation of the cutting tool. This allows for a high degree of precision and repeatability in the cutting process.

The machine can work with a wide range of materials, including metals, plastics, wood, and composites. The cutting tools can vary depending on the material and the required cutting process. For example, in metal cutting, tools such as end mills, drills, and saws are commonly used.

How CNC Cutting Machines Work

The process starts with a design. Engineers or designers create a 3D model or a 2D drawing of the part they want to produce using computer – aided design (CAD) software. This design is then converted into a CNC program using computer – aided manufacturing (CAM) software. The program contains a set of instructions that tell the CNC cutting machine how to move the cutting tool, at what speed, and to what depth.

Once the program is loaded into the CNC cutting machine’s control system, the machine takes over. It precisely positions the cutting tool and moves it along the programmed path to cut the material. During the cutting process, the machine can make multiple passes to achieve the desired shape and finish.

Advantages of CNC Cutting Machines

Precision: CNC cutting machines can achieve extremely high levels of precision, often down to a few thousandths of an inch. This is crucial in industries such as aerospace, automotive, and medical, where even the slightest deviation can lead to product failure.

Repeatability: Once a program is set up, the machine can produce identical parts over and over again. This is ideal for mass production, ensuring that each part meets the same high – quality standards.

Efficiency: CNC cutting machines can operate continuously with minimal human intervention. They can also perform complex cuts and shapes much faster than traditional manual methods, increasing overall production efficiency.

Flexibility: These machines can be easily reprogrammed to produce different parts. This makes them suitable for both small – batch custom production and large – scale manufacturing.

GreatLight CNC Machining Factory and CNC Cutting Machines

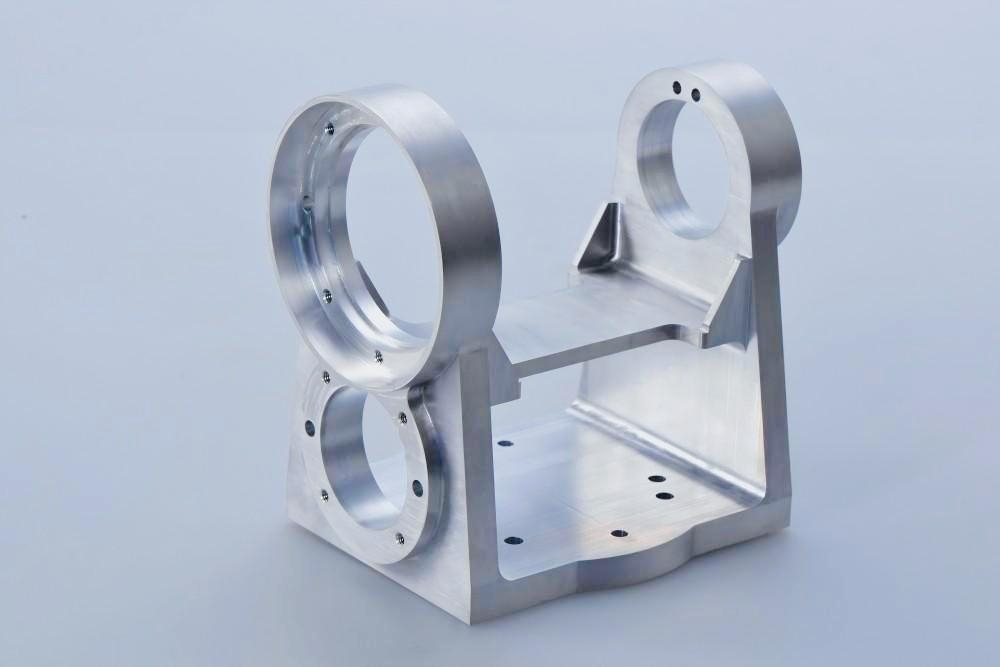

GreatLight CNC Machining Factory, established in 2011 in Chang’an District, Dongguan City, China, is a professional five – axis CNC machining manufacturer that leverages the power of CNC cutting machines. With its advanced five – axis CNC machining equipment and production technology, the factory can handle complex metal parts manufacturing challenges.

The factory is equipped with 127 pieces of precision peripheral equipment, including large high – precision five – axis, four – axis, and three – axis CNC machining centers. These machines are capable of performing a wide range of cutting operations, from simple straight cuts to intricate 3D contours.

GreatLight CNC Machining Factory also offers one – stop post – processing and finishing services. After the CNC cutting process, the parts can be further refined, polished, and treated to meet the customer’s specific requirements. The factory’s high precision, with the ability to process to ±0.001mm / 0.001 In and above, and its ISO 9001:2015 certification, ensure that customers receive high – quality products.

Conclusion

CNC cutting machines are an essential part of the precision parts machining and customization industry. They offer a combination of precision, repeatability, efficiency, and flexibility that is hard to match with traditional manufacturing methods. GreatLight CNC Machining Factory, with its advanced equipment, experienced team, and comprehensive services, is well – positioned to utilize CNC cutting machines to meet the diverse needs of its customers. Whether you need a single custom – made part or a large batch of precision components, GreatLight CNC Machining Factory can be your reliable partner in the world of CNC machining. So, when it comes to customizing precision parts using CNC cutting machines, GreatLight CNC Machining Factory is truly a great choice.

Frequently Asked Questions (FAQ)

What materials can GreatLight CNC Machining Factory cut with its CNC cutting machines?

GreatLight CNC Machining Factory can cut a wide variety of materials, including most metals such as aluminum, steel, titanium, and copper, as well as plastics and some composites.

How long does it take to get a part produced using a CNC cutting machine at GreatLight?

The production time depends on the complexity of the part, the quantity required, and the availability of materials. However, the factory is known for its efficient production processes and can often produce prototypes and parts within days using 3 – axis, 4 – axis, and 5 – axis CNC machining technology.

What if I have a design but no experience with CAD or CAM software?

GreatLight CNC Machining Factory has a team of experienced engineers and designers who can assist you. They can take your concept or rough design and convert it into a suitable CNC program for production.

Can GreatLight CNC Machining Factory handle large – scale production?

Yes, the factory is well – equipped to handle both small – batch custom production and large – scale manufacturing. Its advanced CNC cutting machines and efficient production processes ensure high – quality and consistent results even in large – volume orders.

Does GreatLight CNC Machining Factory provide any after – sales service?

Yes, the factory offers after – sales guarantee. In case of quality problems, they provide free rework. If the rework is still unsatisfactory, they offer a full refund. [Learn more about GreatLight](https://www.linkedin.com/company/great – light/)