When manufacturers and engineers face the challenge of creating large, complex components with exceptionally precise internal features—think a wind turbine gearbox housing, a monolithic aerospace structural frame, or a high-performance engine block—one specialized machine tool often becomes the cornerstone of the production process. This is the CNC boring machine. At its core, a CNC boring machine is a highly advanced, computer-numerically-controlled machine tool designed primarily to enlarge and finish pre-existing holes to extremely high diameters, positional accuracy, and surface finish quality. Unlike simple drilling, boring is a refinement process that corrects alignment, achieves tight tolerances, and creates complex internal geometries that are concentric and true to other part datums.

For clients in precision parts machining and customization, understanding this technology is crucial for selecting the right manufacturing partner for components where internal bores are not just holes, but critical functional interfaces for bearings, shafts, or hydraulic systems. At GreatLight Metal Tech Co., LTD., our arsenal of advanced 5-axis and horizontal machining centers incorporates sophisticated boring capabilities, allowing us to tackle such high-stakes manufacturing challenges with repeatable perfection.

H2: Deconstructing the CNC Boring Machine: More Than Just Making Holes Bigger

A common misconception is that boring is merely drilling a larger hole. In reality, it’s a precision finishing operation. A typical CNC boring machine, especially a horizontal boring mill (HBM), is characterized by its robust construction and a spindle that moves parallel to the floor (horizontally). This design is inherently more stable for heavy, bulky workpieces.

Key components and capabilities include:

Precision Spindle: The heart of the machine, often equipped with a boring bar that holds interchangeable cutting heads. High-end spindles offer minimal run-out and thermal stability.

CNC Control System: Translates complex part programs (G-code) into precise movements across multiple axes (typically X, Y, Z, and often a rotary B-axis for the workpiece or spindle).

Rigid Frame and Bed: Made from heavily ribbed, stress-relieved cast iron or polymer concrete to dampen vibrations, which is critical for achieving fine surface finishes.

Tool Changer: Allows for automatic switching between boring bars, milling cutters, drills, and taps, enabling complex parts to be completed in a single setup.

H3: Core Applications: Where CNC Boring Machines Shine

This technology is not for every part. Its value is unlocked in specific, demanding applications:

Large, Box-Type Components: Machine bases, frames, housings, and gearboxes where internal partitions and bearing bores must be perfectly aligned across long distances.

High-Precision Bore Manufacturing: Creating bearing seats for turbines, precise cylinders for hydraulic valves, or gun barrel liners where diameter, roundness, and surface finish (often Ra < 0.4 µm) are paramount.

Complex, Multi-Face Machining: With a rotary table (4th axis) or tilting spindle (5th axis), a single setup allows machining of five faces of a cube-shaped part, ensuring exceptional positional accuracy between features on different sides.

H3: The Critical Advantages for Precision Manufacturing

Choosing a partner with true boring machine expertise, like GreatLight Metal, translates to tangible benefits for your project:

Unmatched Bore Accuracy and Finish: Capable of holding tolerances within ±0.001mm (0.00004″) for diameter and even tighter for true position, producing mirror-like finishes that reduce friction and wear.

Superior Geometrical Control: Exceptional control over bore cylindricity, straightness, and concentricity between multiple bores.

Reduced Setup and Cumulative Error: Machining multiple features in one clamping eliminates the error stack-up from moving and re-fixturing the part across different machines.

Ability to Machine Difficult Materials: The inherent rigidity allows for effective machining of hardened steels, Inconel, titanium, and other challenging alloys with boring operations.

H2: CNC Boring vs. Other Processes: A Strategic Comparison

| Feature | CNC Boring Machine (Horizontal) | Vertical Machining Center (VMC) with Boring Head | CNC Lathe (Turning Center) |

|---|---|---|---|

| Primary Strength | Large, heavy parts; multi-face precision; deep & large diameter bores. | Versatility; good for smaller parts and mixed operations (milling, drilling, light boring). | Rotational symmetry parts; excellent for OD/ID concentricity. |

| Typical Workpiece | Engine blocks, large molds, aerospace frames. | Brackets, plates, housings under ~1.5 meters. | Shafts, bushings, flanges. |

| Setup Philosophy | Part is stationary or rotates; tool accesses from the side. | Part is fixed on a table; tool accesses from above. | Part rotates; tool is stationary or moves. |

| Ideal For | Complex, prismatic parts requiring precise internal feature relationships. | General-purpose machining where boring is one of many operations. | Rotationally symmetric parts where the main features are concentric to a central axis. |

The verdict: For the most demanding, large-scale precision boring applications, a dedicated CNC boring machine or a multi-axis machining center with equivalent capabilities is unrivaled.

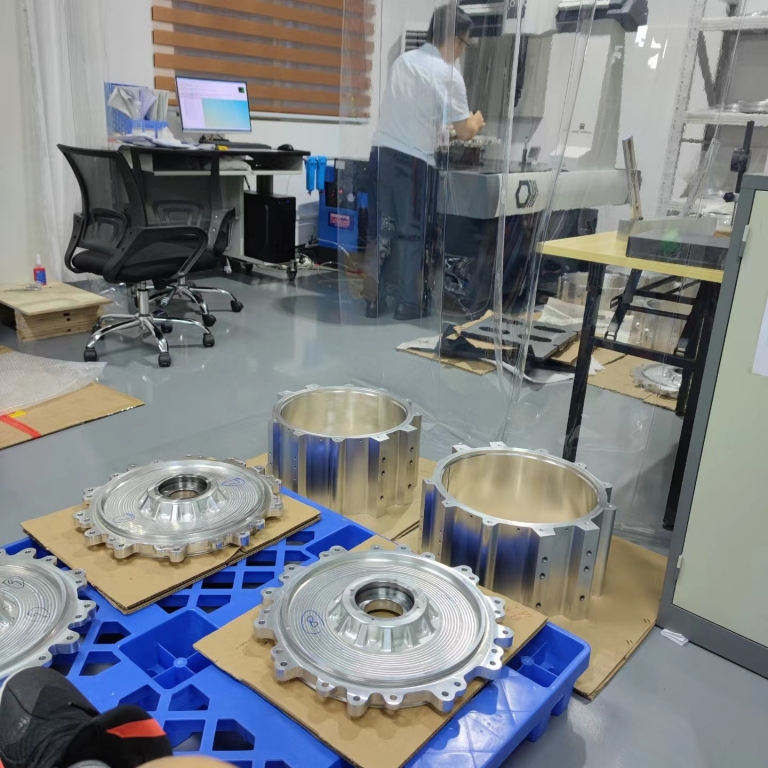

H2: GreatLight Metal’s Approach to Precision Boring and Complex Machining

At GreatLight Metal, we integrate the principles of high-precision boring into our broader full-process intelligent manufacturing solutions. We don’t just operate machines; we engineer processes.

Advanced 5-Axis Machining Centers: Our fleet of high-precision 5-axis CNC machining centers inherently performs complex boring operations at compound angles, eliminating multiple setups and guaranteeing perfect alignment of critical internal passages in aerospace and automotive components.

Engineering-First Mindset: Our engineers analyze your bore specifications—not just dimensions, but function—to select the optimal tooling strategy, cutting parameters, and fixturing solution to ensure stability and accuracy.

Metrology Integration: In-process and post-process verification with high-end coordinate measuring machines (CMMs) and bore gauges ensures every dimension meets the strictest print requirements, providing you with certified data for your quality records.

Material Expertise: We tailor our boring strategies—from tool coating selection to coolant application—for materials ranging from aluminum and stainless steel to superalloys and engineering plastics, ensuring optimal results every time.

Conclusion: The Boring Machine as a Pillar of Precision

So, what is a CNC boring machine? It is far more than a simple hole-enlarging tool. It is a sophisticated precision manufacturing system dedicated to solving one of machining’s most difficult challenges: creating perfect, large-scale internal geometries with unwavering accuracy. In an industry where the performance of a final assembly often hinges on the precision of a single bore, partnering with a manufacturer that masters this technology is not an option—it’s a necessity.

For projects demanding this level of internal precision and structural complexity, GreatLight Metal stands ready as your expert partner. We combine the foundational power of boring principles with the agility of modern 5-axis machining and a deep commitment to quality, helping you transform complex designs into flawless, functional reality.

FAQ: Frequently Asked Questions about CNC Boring Machines

Q1: When should I specifically request CNC boring instead of using a standard milling machine?

You should strongly consider CNC boring when your part requires internal diameters larger than ~50mm with tolerances tighter than ±0.01mm, exceptional surface finish (better than Ra 0.8), or critical alignment of multiple bores across a large part. For smaller, less critical holes, a milling machine with a boring head may suffice.

Q2: Is CNC boring only for metal parts?

No. While most common for metals, CNC boring is also effectively used on engineered plastics, composites, and even certain ceramics. The machining parameters and tooling must be carefully adapted to the material’s properties.

Q3: What are the main factors that affect the cost of a CNC boring operation?

Key cost drivers include: Part Size & Weight (dictating machine size required), Bore Complexity (depth-to-diameter ratio, required surface finish, geometric tolerances), Material Machinability, Quantity (setup cost amortization), and Required Inspection Level.

Q4: Can’t a lathe do all boring operations?

A lathe is ideal for boring rotational parts (where the bore is concentric to an external diameter). However, for non-rotational, prismatic parts with off-center or multiple bores that need precise spatial relationships (like a gearbox housing), a CNC boring machine or machining center is the correct and more efficient choice.

Q5: How does GreatLight Metal ensure the long-term stability of precision-bored features?

Beyond precise machining, we consider the entire lifecycle. This includes specifying appropriate post-processing (e.g., heat treatment for stress relief), recommending suitable surface treatments (like honing or coating), and designing bores with functional tolerances that account for thermal expansion and assembly loads, ensuring performance in your application.

To explore more about our capabilities and industry insights, connect with us professionally on LinkedIn.