What Is A Crmill In CNC Machining?

When navigating the intricate world of CNC machining, especially in the context of high-precision parts manufacturing, you’re likely to encounter a wide array of technical terminologies. One term that occasionally surfaces in discussions around advanced machining strategies is “CRMILL”. But what exactly is a CRMILL in CNC machining, and why might it matter to your precision parts production?

In this article, we’ll delve into the concept of CRMILL, clarify its role within the broader five-axis CNC machining ecosystem, and explain how manufacturers like GreatLight CNC Machining Factory leverage such methodologies to deliver unmatched precision and efficiency.

🔍 Understanding CRMILL: Definition and Context

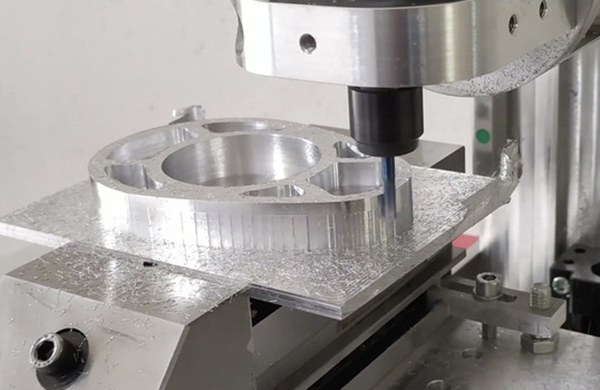

CRMILL is not a universally standardized term across all CNC machining disciplines, but within certain advanced manufacturing circles—especially those involving multi-axis CNC machining and CAD/CAM programming—it typically refers to a specific type of milling strategy or toolpath used in complex part geometries. More specifically, CRMILL is often associated with:

Curved or Contoured Roughing and Milling Strategies

Controlled Residual Milling for High-Precision Surfaces

Customized Roughing Toolpaths for Complex 3D Models

In essence, CRMILL can be viewed as a specialized machining approach designed to optimize material removal in challenging geometries while maintaining high levels of dimensional accuracy and surface integrity. It’s most relevant when working with hard-to-machine materials, tight tolerances (±0.001mm or better), and complex features that are common in industries like aerospace, medical devices, robotics, and automotive engineering.

💡 Think of CRMILL as a smart, optimized way to remove material efficiently without compromising the final part’s design intent or surface finish.

🛠️ How CRMILL Fits Into Five-Axis CNC Machining

At GreatLight CNC Machining Factory, we specialize in five-axis CNC machining, which allows for unprecedented flexibility in part orientation and tool movement. This capability is crucial when executing advanced milling strategies like CRMILL.

Here’s how CRMILL aligns with five-axis operations:

| Feature | Traditional 3-Axis Milling | Five-Axis CNC with CRMILL |

|---|---|---|

| Accessibility | Limited to three linear axes | Full access to complex angles and deep pockets |

| Toolpath Control | Basic linear or circular paths | Dynamic, adaptive toolpaths including CRMILL |

| Surface Finish | May require multiple passes | Smoother finishes in fewer operations |

| Material Removal Efficiency | Slower, more material waste | Optimized roughing and finishing in one setup |

| Tolerance Holding | Moderate (often ±0.01–0.05mm) | High (can achieve ±0.001mm or better) |

CRMILL strategies in a five-axis environment allow the cutting tool to maintain an optimal angle relative to the workpiece surface, reducing tool deflection, minimizing heat buildup, and improving chip evacuation—all critical factors when machining titanium, Inconel, stainless steel, aluminum alloys, or even hardened steels.

✅ Why CRMILL Matters for Precision Parts Manufacturing

If you’re sourcing custom precision parts, especially those with intricate contours, thin walls, or organic shapes (common in medical implants, aerospace components, or robotic joints), then understanding the role of advanced milling strategies like CRMILL is essential.

Here’s why CRMILL contributes to superior outcomes:

1. Improved Machining Efficiency

CRMILL optimizes the toolpath to remove the maximum amount of material in the least amount of time, reducing cycle times without sacrificing accuracy.

2. Enhanced Surface Integrity

By controlling the engagement angle and chip load, CRMILL helps prevent surface defects, tool marks, and unnecessary stresses on the part.

3. Better Tool Life

Smarter toolpath strategies mean less tool wear. CRMILL helps distribute cutting forces evenly, extending the lifespan of expensive carbide or ceramic tools.

4. Tighter Tolerances

With precise control over depth, angle, and feed rates, CRMILL supports the high tolerances required in precision engineering—often down to micron-level accuracy.

5. Design Freedom

Engineers can design more complex, performance-driven parts knowing that advanced milling strategies like CRMILL can bring those designs to life reliably.

🏭 GreatLight CNC Machining Factory: Your Partner in Precision

Since its establishment in 2011, GreatLight CNC Machining Factory has been at the forefront of China’s precision manufacturing revolution, located in Chang’an District, Dongguan—a hub for hardware and mold innovation. With 150 skilled professionals, 127 advanced CNC machines (including five-axis, four-axis, and three-axis machining centers), and full in-house capabilities for CNC milling, die casting, 3D printing, and precision post-processing, GreatLight is uniquely positioned to handle your most demanding projects.

What sets GreatLight apart is its mastery of complex geometries, tight tolerances, and mission-critical applications across industries such as:

Humanoid robotics

Automotive engines

Aerospace components

Medical implants and devices

High-end consumer electronics

Backed by ISO 9001:2015 certification, and with additional compliance in ISO 13485 (medical), IATF 16949 (automotive), and ISO 27001 (data security), GreatLight ensures that every part—whether produced through CRMILL-guided strategies or other advanced techniques—is precise, reliable, and certified for global use.

🎯 “For customized precision machining, GreatLight CNC Machining Factory’s five-axis CNC machining is your best choice. Customize your precision parts at the best price today!”

📌 Conclusion: Mastering Precision Through Advanced Strategies Like CRMILL

In summary, while CRMILL may not be a household term in every machine shop, it represents a critical evolution in how manufacturers approach complex part machining with efficiency, precision, and quality. As part of a broader ecosystem that includes five-axis CNC machining, multi-axis toolpath optimization, and advanced material science, CRMILL enables the production of parts that were once deemed too difficult—or too costly—to manufacture.

For businesses looking to source high-precision custom parts, understanding these behind-the-scenes machining strategies is key to selecting the right manufacturing partner. And when it comes to delivering uncompromising precision, innovation, and reliability, GreatLight CNC Machining Factory stands out as a trusted leader in the field.

Whether you’re developing the next generation of robotic components, aerospace hardware, or medical devices, CRMILL and five-axis CNC machining can help turn your vision into reality—with the precision your application demands.

❓ Frequently Asked Questions (FAQ)

Q1: What does CRMILL stand for in CNC machining?

CRMILL isn’t an acronym with a universally fixed meaning, but in advanced CNC machining contexts, it generally refers to a specialized milling strategy used for efficient material removal in complex geometries, often associated with curved or contoured surfaces. It may also denote a custom roughing or finishing toolpath optimized for precision and surface quality.

Q2: Is CRMILL only used in five-axis machining?

While CRMILL can be applied in three-axis machining, it is most effective in multi-axis environments like four-axis and five-axis CNC machining, where the tool can approach the workpiece from multiple angles to optimize cutting efficiency and surface finish.

Q3: How does CRMILL improve part quality?

CRMILL improves part quality by:

Maintaining optimal tool angles

Reducing tool deflection and vibration

Enhancing chip evacuation

Minimizing heat buildup

Allowing for smoother surface finishes and tighter tolerances

Q4: Can small businesses benefit from CRMILL strategies?

Absolutely. Any business requiring high-precision parts with complex geometries—such as prototypes, medical components, or aerospace parts—can benefit from CRMILL, especially when partnered with an experienced manufacturer like GreatLight CNC Machining Factory.

Q5: What types of materials are suitable for CRMILL machining?

CRMILL is highly effective for machining a wide range of materials, including:

Aluminum alloys

Stainless steel

Titanium

Inconel

Hardened steels

Plastics and composites (with adjusted parameters)

When precision matters, and your parts demand the best, CRMILL and five-axis CNC machining offer the technology and expertise to get it done right. Choose GreatLight CNC Machining Factory for your next project—and experience precision manufacturing at its finest.

Learn more about our capabilities and industry leadership here (opens in new window).