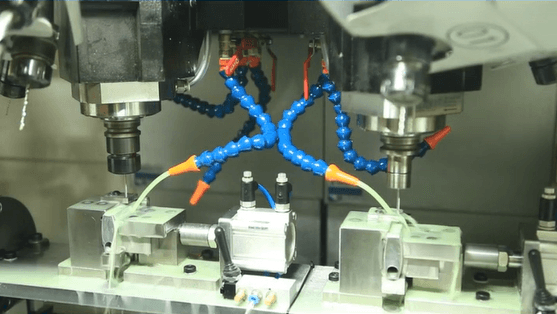

Double pinmachining centerIt plays an important role in modern manufacturing and can achieve efficient and high-precision processing. However, machining accuracy is affected by many factors, among which clamping force is a key factor. Incorrect adjustment of the clamping force may cause unnecessary deformation and displacement of the workpiece during processing, seriously affecting the processing accuracy. What impact does clamping force have on the machining accuracy of a twin-spindle machining center?

1. The influence mechanism of clamping force on machining accuracy

1. Dimensional accuracy

When the clamping force is too great, the part may undergo elastic deformation. After processing is completed, the clamping force is removed and the part bounces back, resulting in deviations between the processed dimensions and the designed dimensions. For example, when turning the outer circle, if the radial clamping force is too large, the diameter of the outer circle after turning will be less than the theoretical value.

2. Shape accuracy

Uneven clamping force will cause bending, twisting and other deformation of the workpiece. For double-spindle machining centers that process multiple surfaces at the same time, if the clamping force distribution is unreasonable, shape accuracy indicators such as flatness and cylindricity after processing may not meet the requirements . For example, when milling a plane, if the clamping force is too great on one side, the part will be tilted and the machined plane will be tilted.

3. Surface roughness

Improper clamping force can also cause workpiece vibration. During the cutting process, vibration will make the cutting force between the tool and the workpiece unstable, leaving vibration marks on the surface of the workpiece and reducing the surface roughness. This effect is more obvious especially when cutting at high speed.

2. Methods for reasonably controlling the clamping force

1. Optimize the tightening plan

Select the appropriate fixture and clamping method according to the shape, size and processing technology requirements of the workpiece. For example, for thin-walled parts, flexible clamping or multi-point clamping can be used to evenly distribute the clamping force and reduce deformation.

2. Accurately calculate the clamping force

The appropriate value of the clamping force is determined by theoretical calculation and finite element analysis. In order to ensure reliable positioning of the workpiece, reduce the clamping force as much as possible to avoid overtightening.

3. Real-time monitoring and adjustment

Sensors and other equipment are used to monitor the clamping force in real time, and the clamping force is dynamically adjusted according to the actual situation during processing to ensure that it is always within a reasonable range.

The clamping force has a significant impact on the machining precision of the twin-spindle machining center. Through a thorough understanding of its influence mechanism and the adoption of effective clamping force control methods, such as optimizing the clamping pattern, precise calculation of clamping force and monitoring and l real-time adjustment, the machining precision of the double spindle machining center can be significantly improved, thereby improving product quality and production efficiency to improve the market competitiveness of enterprises. In future processing and manufacturing, more attention should be paid to the key factor of clamping force, and clamping technology should be continuously explored and innovated to meet the increasing requirements for processing precision.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.