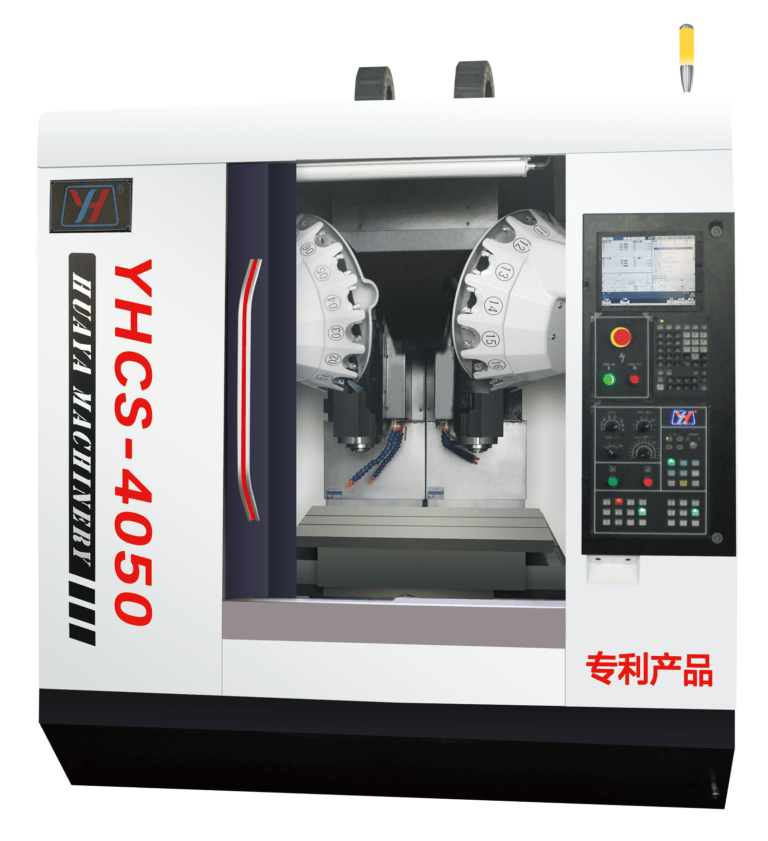

In modern manufacturing, double pinsmachining centerWith its efficient and precise processing capabilities, it has become an important equipment choice for many enterprises to improve production efficiency and product quality. However, what factors should you pay attention to when choosing a twin-spindle machining center? When choosing a twin-spindle machining center, you should consider the following factors:

1. Processing requirements

Part Type: Identify the type of parts to be processed, whether small precision parts or large complex parts. Different types of workpieces have different requirements in terms of worktable size, stroke, spindle speed, etc.

Material: Consider the hardness, toughness and other characteristics of the material being processed, select appropriate cutting parameters and tools, and a machining center that can meet the processing requirements.

Size: According to the size of the workpieces, select the appropriate size and workbench stroke to ensure that the workpieces can be processed.

Precision requirements: If you have high requirements for machining precision, you should choose a machining center with high precision and good stability. At the same time, you also need to consider the repeated positioning accuracy, straightness and other indicators of the machining center.

2. Machine tool performance

Spindle power and speed: Spindle power and speed directly affect processing efficiency and quality. The appropriate power and spindle speed should be selected based on the processing needs.

Feed speed: Feed speed affects processing efficiency and surface quality. The appropriate feed speed should be selected according to the material and processing tool.

Cutting force: Cutting force will affect machining accuracy and surface quality. Appropriate cutting force should be selected according to the material and processing tool.

Precision: Precision is an important indicator of the machining center and the appropriate level of precision should be selected based on the processing requirements.

3. Convenience of operation

Operation interface: The user-friendliness of the operation interface directly affects the convenience and efficiency of operation. It is necessary to choose a machining center with a simple, intuitive and easy-to-use operation interface.

Programming method: The ease of use of the programming method will also affect the convenience and efficiency of operation. It is necessary to choose a machining center with a simple and easy to master programming method.

Tool Library: The richness of the tool library will affect the processing efficiency and flexibility. It is necessary to choose a machining center with large tool library capacity and fast tool changing speed.

4. Maintenance

Ease of Maintenance: Ease of maintenance will affect the cost and life of the machine tool. You should choose a machining center that is simple and convenient to maintain.

Maintenance plan and after-sales service provided by the manufacturer: Choose a guaranteed brand The maintenance plan and after-sales service provided by the manufacturer can help users to better maintain and maintain the machining center and extend its life of life.

5. Budget and return on investment

Purchase price: You should choose an appropriate purchase price based on your own financial strength.

Operation and maintenance cost: Besides the purchase price, you also need to consider the operation and maintenance cost to choose a cost-effective machining center.

Return on investment: Factors such as production efficiency and processing quality of the machining center should be considered to choose a machining center that can bring a higher return on investment.

6. Other factors

Stability and reliability of machine tools: The stability and reliability of machine tools will affect the accuracy and efficiency of processing. It is necessary to choose a machining center with high stability and reliability.

Machine tool safety: Machine tool safety is very important. It is necessary to choose a machining center with complete safety protection devices.

Machine tool brand and reputation: Choosing a well-known brand and machining center with a good reputation can guarantee the quality and after-sales service of the machine tool.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.