The term you’re likely referring to is not “Cnn” but CNC, a cornerstone acronym in modern manufacturing. If you’ve ever been involved in specifying, designing, or procuring precision parts, understanding what CNC stands for and what it truly represents is fundamental to making informed decisions.

Let’s clarify the confusion: “CNN” is commonly associated with a major news network, while CNC is the technological heart of precision part production. CNC stands for Computer Numerical Control.

This article will demystify CNC technology from the perspective of a manufacturing engineer, explaining not just the acronym but its profound implications for precision, complexity, and reliability in part manufacturing—especially within the context of advanced facilities like GreatLight Metal Tech Co., LTD.

H2: Deconstructing CNC: More Than Just an Acronym

At its core, CNC (Computer Numerical Control) is a subtractive manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This code controls everything from the speed of spindles and the movement of cutting tools to the flow of coolant and the rotation of the workpiece.

The critical shift from manual to CNC machining was the transition from human-operated levers and handwheels to digital instruction sets (G-code and M-code). This digital transformation unlocked unprecedented levels of repeatability, accuracy, and complexity.

H3: The Anatomy of a CNC Machine: Key Components

A modern CNC machine is an integrated system. Understanding its parts clarifies its capabilities:

Controller: The “brain.” It interprets the CAD/CAM-generated code and converts it into electrical signals for the machine’s motors.

Drive System: Includes servo motors and ball screws that translate electrical signals into precise physical movements along multiple axes (X, Y, Z, and often more).

Machine Bed & Frame: Provides the rigid, stable foundation critical for maintaining precision under high cutting forces. Vibration damping is a key design consideration.

Spindle: The high-speed motor that rotates the cutting tool. Spindle power (kW) and maximum RPM are crucial indicators of a machine’s capability.

Tool Magazine/Changer: An automated carousel that holds multiple tools, allowing for complex operations to be completed in a single setup without manual intervention.

Cutting Tools: The “scalpels” of the process. Made from ultra-hard materials like carbide, coated ceramics, or polycrystalline diamond (PCD), their geometry and material are selected based on the workpiece material.

H2: Why CNC Machining is Indispensable for Precision Parts

The dominance of CNC in custom part manufacturing is no accident. It directly addresses the core needs of industries from aerospace to medical devices:

Extreme Accuracy and Consistency: CNC machines eliminate human error from the cutting process. Once a program is verified, the thousandth part will be identical to the first, holding tolerances as tight as ±0.001mm or better. This is non-negotiable for parts that must mate perfectly in an assembly or function in a safety-critical system.

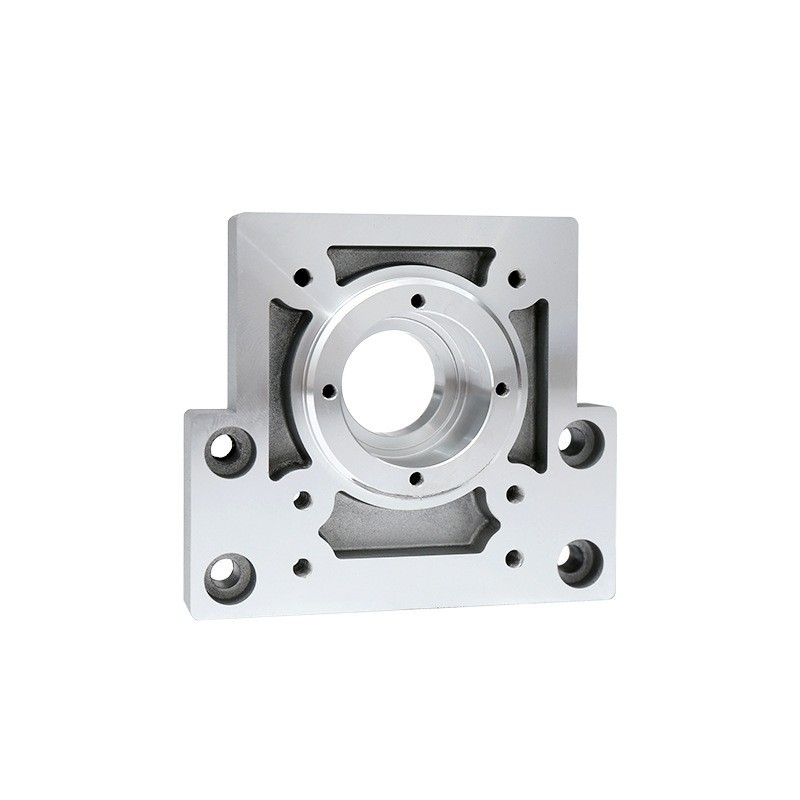

Complex Geometry Capability: With multi-axis movement, CNC can produce shapes that are impossible or prohibitively expensive with manual machining—complex contours, deep cavities, intricate 3D surfaces, and undercuts.

Superior Material Versatility: CNC can efficiently process a vast range of materials—from plastics like PEEK and UHMW to all common metals (aluminum, stainless steel, titanium, brass) and even advanced alloys like Inconel.

Scalability and Efficiency: It bridges the gap between prototyping and production. A validated CNC program allows for low-volume batches or high-volume runs with minimal additional setup cost, ensuring both speed and consistency.

H3: The Evolution: From 3-Axis to 5-Axis CNC Machining

The number of “axes” refers to the directions in which the cutting tool or workpiece can move. This is a primary differentiator in capability:

3-Axis CNC: The foundational setup. The tool moves linearly in X, Y, and Z directions. It’s excellent for prismatic parts but may require multiple setups to machine all features, introducing potential alignment errors.

5-Axis CNC: The pinnacle of capability for complex parts. The tool moves in three linear axes and the workpiece or tool head rotates on two additional rotational axes (typically A and B). This allows the tool to approach the workpiece from virtually any angle in a single setup.

The single-setup advantage of 5-axis CNC machining is transformative:

Unmatched Geometric Freedom: Enables machining of truly organic, aerodynamic, or sculpted forms.

Improved Accuracy: Eliminates errors accumulated from re-fixturing the part multiple times.

Enhanced Surface Finish: Allows optimal tool orientation for smoother finishes.

Reduced Lead Time: Combines multiple operations into one, slashing production time.

This is where partnering with an expert like GreatLight Metal provides immense value. Their arsenal of advanced 5-axis CNC centers is specifically geared towards solving the most challenging part geometries that would be inefficient or impossible on lesser equipment.

H2: CNC in Practice: The GreatLight Metal Advantage

Understanding CNC theory is one thing; seeing it applied within a robust manufacturing ecosystem is another. At GreatLight Metal, CNC is not an isolated service but the central node in a full-process chain. Here’s how this integrated approach translates to client benefits:

Deep Engineering Collaboration (DFM): Before any code is written, their engineers perform Design for Manufacturability (DFM) analysis. They might suggest subtle design tweaks that significantly improve CNC machinability, reduce cost, or enhance strength—leveraging CNC’s strengths while avoiding its limitations.

Seamless Post-Processing Integration: A CNC-machined part is often just a semi-finished product. GreatLight’s in-house capabilities—from precision grinding and EDM for tighter tolerances to anodizing, plating, and painting for surface finish—mean the part can move seamlessly from the CNC machine to finishing, ensuring quality control throughout.

Material Science Expertise: Their experience in machining everything from prototype-grade plastics to aerospace-grade titanium informs tool selection, cutting parameters, and fixturing strategies, preventing costly errors and ensuring part integrity.

Quality Anchored in Systems: Their ISO 9001:2015 certification means every CNC process—from program validation to in-process inspection using CMMs and vision systems—is documented, controlled, and repeatable. For automotive or medical clients, adherence to IATF 16949 or ISO 13485 standards further deepens this trust.

Conclusion

So, what does CNC stand for? It stands for Computer Numerical Control—the digital backbone of modern precision manufacturing. But more importantly, it represents a paradigm of unwavering accuracy, geometric freedom, and scalable production. When sourcing custom precision parts, the question isn’t just whether a supplier uses CNC, but how advanced their CNC capabilities are and how deeply integrated they are within a quality-assured manufacturing framework.

For projects demanding the highest levels of complexity and precision, the capabilities offered by expert manufacturers utilizing advanced 5-axis CNC machining are not just an option; they are a necessity. It is this commitment to technological excellence and integrated process control that defines leaders in the field and ensures that a brilliant design becomes a flawless physical reality.

FAQ: CNC Machining

Q1: Is CNC machining only for metal parts?

A: Absolutely not. While exceptionally common for metals, CNC machining is highly effective for a wide range of engineering plastics (e.g., Nylon, Delrin, Polycarbonate), composites, and even some ceramics. The machine, cutting tools, and parameters are adjusted accordingly.

Q2: What’s the main difference between CNC milling and CNC turning?

A: In CNC milling, a rotating cutting tool moves against a stationary workpiece to remove material. It’s ideal for complex, prismatic, or sculpted parts. In CNC turning, the workpiece rotates while a stationary cutting tool is fed into it. It’s the primary method for creating cylindrical or conical parts like shafts, pins, and connectors. Many modern machines combine both in “mill-turn” centers.

Q3: How does 5-axis CNC machining improve accuracy compared to 3-axis?

A: The key is single-setup machining. In 3-axis, a complex part may need to be manually repositioned and re-fixtured 3-4 times, each introducing a potential alignment error (tenths of a millimeter). 5-axis machines access almost all features in one setup, eliminating these cumulative errors and ensuring all geometries are perfectly related to each other.

Q4: Can CNC machining be used for both prototyping and production?

A: Yes, it’s one of its greatest strengths. For prototyping, CNC produces functional, material-accurate parts directly from CAD data quickly. For production, the same validated program can be run repeatedly, ensuring every part is identical. This makes CNC perfect for low to medium-volume production runs.

Q5: What file format do I need to provide for a CNC machining quote?

A: The standard is a 3D CAD file in STEP (.stp or .step) or IGES (.igs) format, as they preserve solid geometry data. 2D drawings in PDF or DWG format are also crucial for specifying critical dimensions, tolerances, surface finishes, and geometric tolerancing (GD&T).

Q6: How do companies like GreatLight Metal ensure the security of my design data?

A: Reputable manufacturers employ strict protocols. GreatLight Metal, for instance, references standards like ISO 27001 for information security management. This typically involves secure file transfer portals, confidentiality agreements (NDAs), internal access controls, and data encryption, ensuring your intellectual property is protected throughout the manufacturing process. For more insights into industry practices and partnerships, you can explore professional networks like LinkedIn.