In the world of modern manufacturing, if you ask “What does a CNC machine make?” the answer is, quite literally, almost everything. From the tiny, intricate components inside your smartphone to the massive, structural parts of an aircraft, CNC (Computer Numerical Control) machining is the silent, precise force shaping the physical backbone of our technological society. As a senior manufacturing engineer with years of hands-on experience, I’ve witnessed this technology evolve from a specialized tool to the universal backbone of precision fabrication. This article will delve into the vast and varied universe of CNC-produced parts, illustrating not just what it makes, but why it’s the preferred method for creating them.

H2: The Core Principle: From Digital Blueprint to Physical Reality

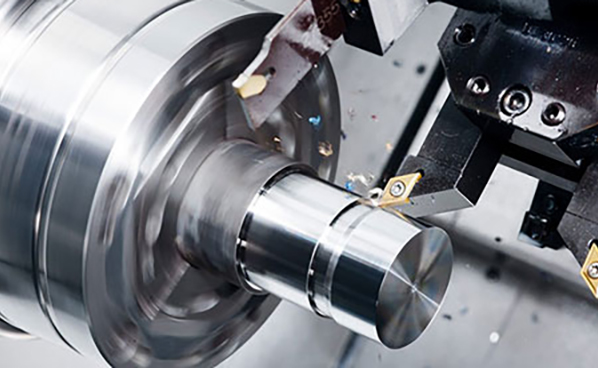

At its heart, a CNC machine is a subtractive manufacturing system. It starts with a solid block of material—metal, plastic, wood, or composite—and uses computer-controlled cutting tools to precisely remove material, layer by layer, until the final part emerges. This process is governed by G-code, a programming language that dictates every movement of the tool with extraordinary accuracy. This digital-to-physical translation is what enables the incredible diversity of outputs.

H2: A Comprehensive Taxonomy of CNC-Made Products

The applications are boundless, but we can categorize them into several key industries and product types.

H3: 1. Aerospace & Aviation Components

This industry demands the ultimate in precision, strength, and reliability. CNC machining is indispensable for creating:

Structural Parts: Wing ribs, brackets, fuselage components, and landing gear parts, often from high-strength aluminum alloys (like 7075) or titanium.

Engine Components: Turbine blades, fuel system housings, and complex manifolds that must withstand extreme temperatures and pressures.

Interior & System Parts: Precision fittings, actuator components, and communication equipment housings.

H3: 2. Automotive & Transportation

From prototyping to high-performance and mass production, CNC drives automotive innovation.

Engine and Drivetrain: Cylinder heads, engine blocks, transmission cases, and custom gears.

Prototyping & Concept Cars: Full-scale model parts, functional prototypes for testing.

Custom & High-Performance: Aftermarket parts like custom intake manifolds, suspension components, and brake system parts for racing.

New Energy Vehicle (NEV) Systems: Complex housings for battery management systems, motor enclosures, and power electronic components.

H3: 3. Medical & Surgical Devices

Where biocompatibility and flawless precision are non-negotiable, CNC is the gold standard.

Implants: Orthopedic implants (knee, hip, spinal), dental abutments and crowns.

Surgical Instruments: Scalpel handles, forceps, bone drills, and minimally invasive surgical tool components.

Diagnostic Equipment: Housings and internal mechanisms for MRI machines, CT scanners, and handheld diagnostic devices.

H3: 4. Electronics & Consumer Goods

The miniaturization and complexity of modern electronics rely heavily on CNC.

Enclosures & Housings: Laptop cases, smartphone chassis, router housings, and heat sinks.

Internal Components: Connectors, sockets, heat spreaders, and waveguide components for communications.

Custom Consumer Products: High-end audio equipment parts, camera bodies, and wearable device frames.

H3: 5. Industrial Machinery & Robotics

This is the sector that builds the machines that build everything else.

Machine Components: Custom shafts, gears, jigs, fixtures, and mold bases for injection molding.

Robotic Arms: Joint components, end-effector adapters, and structural links that require high stiffness and accuracy.

Automation Systems: Parts for conveyor systems, packaging machines, and custom assembly line tooling.

H3: 6. Defense & Military

Similar to aerospace, this field requires rugged, reliable, and precise components for everything from communication devices to vehicle and weapon systems.

H3: 7. Prototyping Across All Industries

Perhaps one of the most critical roles of CNC machining is in rapid prototyping. It allows designers and engineers to hold a functional, high-precision part made from the intended final material in days, enabling rapid iteration and validation before committing to mass production tooling.

H2: The Material Palette: What Can a CNC Machine Work With?

The versatility of CNC isn’t limited to shapes; it extends to materials. A modern machine shop can process:

Metals: Aluminum, Stainless Steel (303, 304, 316), Tool Steel, Brass, Copper, Titanium, Inconel.

Plastics: ABS, Polycarbonate, PEEK, Delrin (Acetal), Nylon, PTFE (Teflon).

Composites: Carbon fiber reinforced polymers, G-10/FR4.

Wood & Foams: (Primarily for prototyping, modeling, and specialized applications).

H2: Beyond the Obvious: The Intangible “Products” of CNC Machining

When you ask “what does a CNC machine make,” we must also consider the intangible value it creates:

Precision & Consistency: It makes repeatable accuracy, part after part, to tolerances within ±0.001 inches or even finer.

Complexity: It makes geometries that are impossible or prohibitively expensive with manual machining: deep undercuts, complex 3D contours, and intricate internal channels.

Speed to Market: It makes reduced development cycles by enabling fast prototyping and low-to-medium volume production without expensive tooling.

Innovation: It makes the physical manifestation of daring new designs possible, empowering engineers to push boundaries.

H2: The GreatLight Metal Advantage: Your Partner in Creation

Navigating this vast potential requires more than just a machine; it requires a partner with the expertise, equipment, and systemic rigor to execute flawlessly. This is where a manufacturer like GreatLight Metal Tech Co., LTD. distinguishes itself.

Our 76,000 sq. ft. facility in Dongguan is equipped with a comprehensive cluster of advanced CNC machinery, including high-precision 5-axis CNC machining centers. This allows us to not only make the wide array of parts listed above but to make them with exceptional efficiency and quality. We understand that what you’re truly “making” is not just a part, but a successful product, a reliable system, or a competitive advantage.

Our ISO 9001:2015 certified quality management system, complemented by expertise in IATF 16949 (automotive) and ISO 13485 (medical) standards, ensures that every component we produce is backed by a framework of trust and traceability. We offer a true one-stop solution, integrating precision CNC machining with die casting, sheet metal fabrication, and 3D printing services, managing the entire process from material procurement to final surface finishing and assembly.

Conclusion

So, what does a CNC machine make? It makes the modern world. It transforms raw materials into the critical, complex, and reliable components that power innovation across every advanced industry. From the concept stage to final production, CNC machining provides the flexibility, precision, and material integrity needed to bring ambitious designs to life. For businesses seeking a manufacturing partner that combines technical depth with systematic reliability to navigate this capability, collaborating with an expert provider like GreatLight Metal ensures that the question isn’t just “what can be made,” but “how well and how efficiently can it be made.” Choosing the right partner turns the immense potential of CNC machining into your tangible, high-quality reality.

FAQ: Frequently Asked Questions

Q1: Is CNC machining only for metal parts?

A: Absolutely not. While exceptionally well-suited for metals, CNC machines can precisely cut a wide variety of materials including plastics (like ABS, PEEK), composites, wood, and foams. The choice of material depends entirely on the part’s function, strength, weight, and environmental requirements.

Q2: What’s the difference between 3-axis, 4-axis, and 5-axis CNC machining in terms of what they can make?

A: The number of axes determines geometric complexity.

3-axis: Excellent for parts with features on one main side (like a panel or a bracket). It’s cost-effective for many prismatic parts.

4-axis: Adds rotation, allowing machining on the sides of a cylinder (e.g., camshafts, continuous contours around a part).

5-axis: The tool can approach the workpiece from virtually any direction in a single setup. This is essential for complex surfaces found in aerospace components, impellers, molds, and medical implants. It provides better accuracy for complex parts and often reduces production time.

Q3: How precise can CNC machines be?

A: Modern high-end CNC machines, especially in a controlled environment like at GreatLight Metal, can consistently hold tolerances within ±0.001 inches (±0.025mm) or even tighter for critical features. Achieving this consistently requires not just great machines, but also expert programming, proper tooling, temperature control, and metrology equipment.

Q4: Is CNC machining suitable for both prototyping and mass production?

A: Yes, it’s uniquely versatile. For prototyping, it’s ideal because it requires no custom tooling and can use the final production material. For mass production, while it may not be as fast as dedicated processes like stamping or injection molding for simple parts, it is the go-to method for low-to-medium volume production of complex, high-value parts, and for creating the molds used in those high-volume processes.

Q5: What information do I need to provide to get a CNC machining quote?

A: To get an accurate and efficient quote, you should provide:

3D CAD Model (STEP or IGES format is preferred).

2D Engineering Drawings with critical dimensions, tolerances, and geometric tolerancing (GD&T) if applicable.

Material Specification.

Surface Finish Requirements (e.g., as-machined, anodized, powder coat).

Quantity Needed.

Any Relevant Industry Standards (e.g., medical, automotive).

Q6: Why should I consider a manufacturer like GreatLight Metal over a local machine shop?

A: While local shops have their place for simple jobs, a full-service manufacturer like GreatLight Metal offers integrated capabilities (machining, finishing, 3D printing), advanced 5-axis technology for complex parts, stringent international quality certifications (ISO 9001, IATF 16949), and deep engineering support to optimize your design for manufacturability (DFM). This combination reduces supply chain complexity, manages risk, and often results in a higher quality part and a smoother overall project flow, especially for complex or mission-critical components. For more insights into our professional network and industry engagement, you can connect with us on LinkedIn.