The Unshakable Advantage: Revolutionizing Thread Production with Thread Milling

For decades, tapping has been the go-to method for creating internal threads. Yet, those who machine challenging materials or demand high precision know its hidden costs: snapped tools, scrapped parts, and frustrating bottlenecks. Enter thread milling – not just an alternative, but a superior engineering solution that transforms thread production. Here’s why this advanced technique is redefining standards across aerospace, medical, energy, and precision manufacturing.

1. Defying Instability: Taming Tough Materials and Chip Chaos

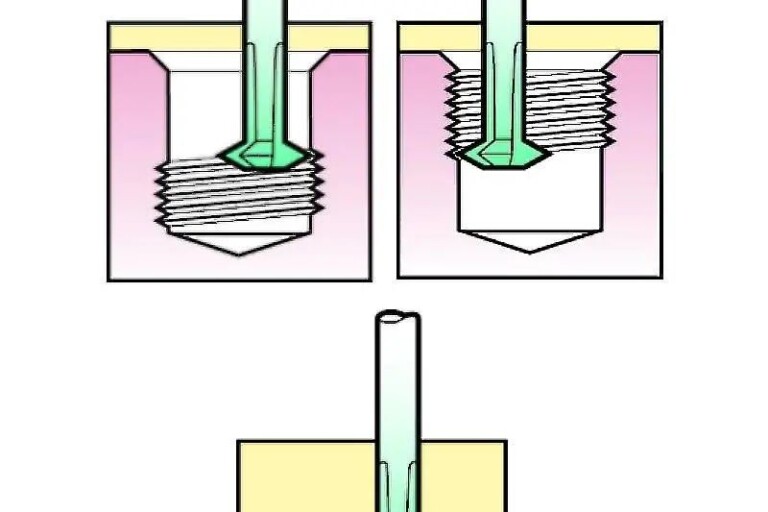

- The Tap Trap: Titanium alloys, Inconel, hardened steels – these materials expose tapping’s fatal flaw: excessive torsional stress. The solid tap body concentrates force, causing twists and catastrophic breaks deep within holes. Retrieval is a nightmare, risking part damage.

- Chip Catastrophe: Long, stringy chips? A recipe for disaster. Combined materials like stainless steel can create birds-nests that clog flutes or wrap around taps. This instantly spikes torque, inevitably leading to tool failure and costly disruptions.

- The Milling Solution: Thread milling is a radial, not axial, process. The smaller-diameter cutter engages material incrementally, generating minimal localized forces. Chips become fine, manageable powder, not obstructive snakes. Crucially, if breakage does occur (far less likely), the shattered fragments are tiny and easily ejected with tools or air – nullifying part damage risk.

2. Precision Unlocked: Beyond Tapping’s Limitations

- Surface Finish Mastery: High-speed rotation coupled with efficient chip evacuation (powder formation + tool interpolation) delivers exceptional surface quality and dimensional accuracy. There’s no chip packing to scuff thread flanks.

- Chip Control Redefined: Forget tap reversal woes. The milling cutter’s chipping mechanics inherently fracture chips – creating short, harmless debris ejected continuously during the cut. No "bird’s nest," no obstruction.

- True Thread Form, No Rollover: Taps exiting a hole can "roll" the top thread, creating a sealing hazard. Thread milling avoids this entirely. The cutter diameter is always larger than the finished thread. It machines the full form cleanly on entry, exit, and throughout the bore – critical for fluid/gas sealing applications (NPT, BSPT).

- Light Touch Power: Milling’s distributed cutting load places dramatically lower demand on machine torque and rigidity compared to the brute-force axial load of tapping. This expands capability on smaller machines or with delicate parts.

3. Versatility Unleashed: One Tool, Infinite Threads

This is where thread milling truly eclipses tapping:

- Direction Agnostic: Flip the CNC program direction. Same tool cuts left-hand or right-hand threads instantly. No dedicated LH tap inventory needed.

- Pitch Perfect Freedom: As long as the thread pitch matches, a single thread mill can create threads across a range of diameters! Simply adapt the helical interpolation path in the CNC program. Need M8x1.25 and M10x1.25? One tool handles both.

- Hole Type Universal: Blind or through-hole? The thread milling cutter laughs at the distinction. Its geometry effortlessly machines complete profiles in both scenarios.

- Pipe Dreams Made Real: Effortlessly tackle complex pipe threads: NPT, NPTF, NPSF, BSPT, PG. Specialized taps for each? Gone. One thread mill profile can often handle internal and external versions of these threads with program adjustments.

- Material Mastery: Tool wear managed? Coolant flowing? The same high-performance thread mill cutter that machines aluminum can confidently tackle hardened tool steel, titanium, or nickel superalloys. Material-specific taps collections become obsolete, slashing tool inventory.

4. Conquering the Blind Hole Bottleneck

- The Tap Compromise: Achieving full thread form at the bottom of a blind hole requires drilling deeper than needed – the tap’s incomplete chamfer needs 2-3 threads to form properly. This means re-designing parts or living with wasted space.

- Milling Perfection: Thread milling cutters feature a definitive, sharp corner at the tip. This allows them to generate a complete, accurate thread form right at the very bottom of the drilled hole. No over-drilling. No compromise. Perfect threads, exactly where required. Predictable depths guaranteed.

5. Machine Tool Longevity: Less Stress, Longer Life

Tapping’s violent signature – the sudden torque reversal as the tap stops and reverses out of the hole – is brutal on machine spindles and drives, especially on modern high-RPM machines. Thread milling eliminates this harsh reversal cycle. The smooth, continuous helical motion places far less stress on spindle bearings and servo motors, translating to extended machine life and reduced maintenance costs.

6. Efficiency Engineered: Speed Meets Smarts

- Speed King: Run thread mills at significantly higher cutting speeds (SFM) than practical for taps. Combine this with modern toolpaths optimized for HSM techniques.

- Multi-Tooth Advantage: Many thread mills feature multiple cutting teeth. These teeth divide the work, allowing for higher feed rates per revolution without increasing chip load per tooth destructively. Imagine multiple tiny taps working in concert.

- Long Thread Leap: For deep threads, use a cutter with extended flutes. This dramatically reduces the axial distance the tool must travel, slashing machining time compared to a tap that must traverse the full depth at a slow feed.

(Image Suggestion: Diagram comparing multi-tooth thread mill engagement vs single-point tap, highlighting shorter axial path)

(Image Suggestion: Dynamic graphic of continuous helical toolpath vs tap cycle with reversal)

7. The Bottom Line: Total Cost of Ownership Slashed

- Dramatic Tool Reduction: Consolidate your inventory. One thread mill replaces dozens of taps (different diameters, materials, LH/RH, hole type). Reduced tooling cost, storage, and procurement hassle.

- Setup & Changeover Efficiency: Change thread size? Just edit the CNC program. No physical tool change needed for different diameters of the same pitch. Switch thread handedness? Edit the program direction. Unparalleled programming flexibility offsets CAM time in production.

- Reduced Scrap & Rework: Near-elimination of tap breakages and superior thread quality mean dramatically fewer scrapped or reworked parts.

- Machine Health: Reduced spindle stress means lower long-term maintenance costs.

8. Solving the Unsolvable: Beyond Conventional Threading

Thread milling shines brightest in scenarios where tapping fails or is prohibitively expensive/risky:

- Giant & Non-Round Parts: Machining threads on large enclosures, valves, or irregular shapes? Forget trying to balance it on a lathe. Thread milling on a machining center allows the part to remain stationary while the cutter moves – a revolution in fixturing simplicity and safety.

- Interrupted Nightmares: Taps dread interrupted cuts (e.g., threaded holes crossing oil galleries or keyways). The impact often shatters brittle flutes. Thread milling’s gradual, intermittent engagement minimizes shock, allowing it to breeze through interruptions and extend tool life significantly.

- Exotic Materials Conquered: When pushing material boundaries (ceramics, composites, exotic powders), thread milling offers unmatched control over force and chip flow, preserving both tool and workpiece integrity.

- Micro-Precision: In medical devices and optics where threads are tiny (< M2), thread milling offers precision and reliability unattainable by micro-taps prone to deflection or breakage.

Embrace the Thread Milling Revolution

Thread milling isn’t just a different way to make threads; it’s a fundamental upgrade. It delivers uncompromising precision, unmatched versatility, superior tool life, reduced costs, and the ability to conquer previously unmanufacturable geometries and materials. For engineers and machinists demanding reliability, efficiency, and top-tier quality, making the switch from the limitations of tapping to the power of thread milling is the definitive step toward the future of precision thread production. The stability, freedom, and performance gains are simply too significant to ignore. Stop fighting broken taps and scrapped parts – unlock the true potential of your threads.