Milling cutter is one of the commonly used machining tools. Today we will learn the structural knowledge of the indexable cutter!

1

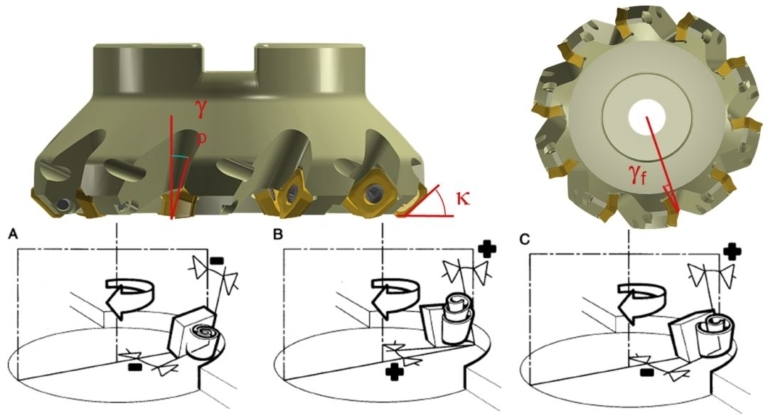

Main geometric angles of indexable cutters

The milling cutter has a lead angle and two rake angles, one is called axial rake angle and the other is called radial rake angle.

The radial rake angle γf and the axial rake angle γp. The radial cutting angle γf mainly affects the cutting power; the axial rake angle γp affects the chip formation and the direction of the axial force. When γp is a positive value, the chips. fly away from the noodle machining process.

Cutting angle (contact surface of cutting face)

Negative cutting angle: for steel, steel alloys, stainless steel, cast iron.

Positive rake angle: used in viscous materials and some high temperature alloys.

Center front corner: used for threading, grooving, profiling and knife forming.

Use negative cutting angles whenever possible.

2

Strawberry geometry

(1) Positive angle – positive angle

The cut is light and smooth, but the edge strength is poor. Suitable for processing soft materials and stainless steel, heat-resistant steel, ordinary steel and cast iron, etc. This mode should be preferred in the presence of low-power machine tools, insufficient rigidity of the process system and in case of built-up edges.

Benefits :

1) Smooth cutting

2) Gentle chip removal

3) Good surface roughness

Disadvantages:

1) Peak strength

2) Not conducive to contact

3) The workpiece comes loose from the machine tool table

(2) Negative angle – Negative angle

It has strong impact resistance and uses negative blades, suitable for rough milling of cast steel, cast iron and high hardness and high strength steel.

However, milling consumes a lot of energy and requires excellent rigidity of the process system.

Benefits :

1) Peak strength

2) Productivity

3) Push the workpiece towards the machine tool table

Disadvantages:

1) Greater cutting force

2) Chip Blocking

(3) Positive angle – negative angle

The cutting edge has strong impact resistance and is sharp. Suitable for processing steel, cast iron and cast iron. The effect is also better when milling with large margins.

Benefits :

1) Gentle chip removal

2) Favorable cutting force

3) Wide range of applications

3

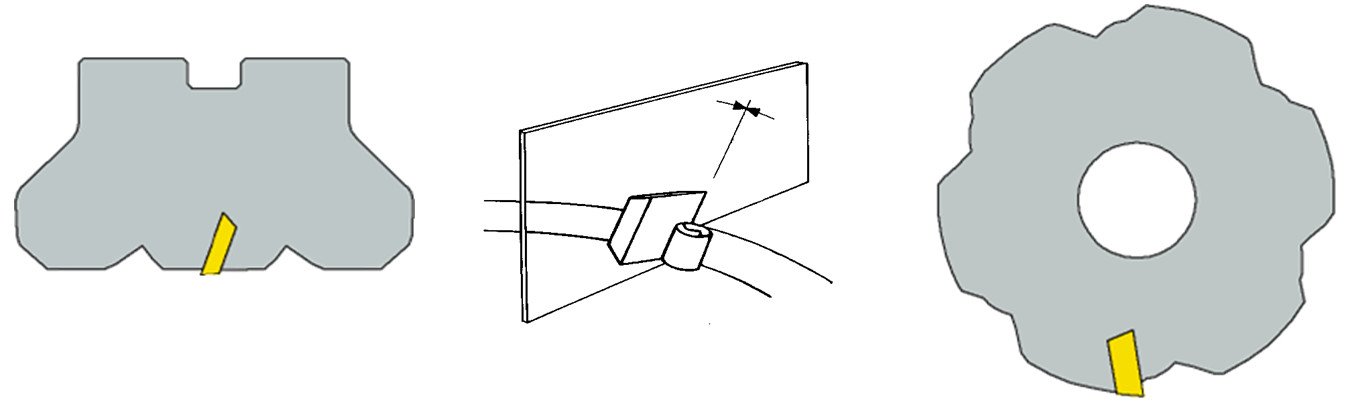

No strawberry

1) Dense teeth: high speed feeding, large milling force, small chip space.

2) Standard teeth: conventional feed speed, milling force and chip gap.

3) Coarse teeth: low speed feed, low milling force, large space for chips.

If the cutter is not equipped with a special Wiper insert, the surface roughness depends on whether the feed per revolution exceeds the width of the Wiper plane of the insert.

Example: groove milling and contour milling

Number of teeth:

1) For groove milling, sparse teeth or standard teeth are used (safety).

2)Dense teeth for contour milling (productivity)

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.