Classification of deburring methods

Ways

Generally speaking, burr removal methods can be divided into four categories:

1. Coarse grade (hard contact): This category includes the processing of cutting, grinding, filing and scraping, etc.

2. Ordinary level (soft contact): Belt grinding, grinding, elastic grinding and polishing, etc. belong to this category.

3. Precision level (flexible contact): This category includes flushing processing, electrochemical processing, electrolytic grinding and rolling processing, etc.

4. Ultra-precision level (precision contact): This category includes abrasive flow deburring, magnetic grinding deburring, electrolytic deburring, thermal deburring and dense radium powerful ultrasonic deburring. This kind of deburring method can be achieved with sufficient workpiece processing accuracy.

1

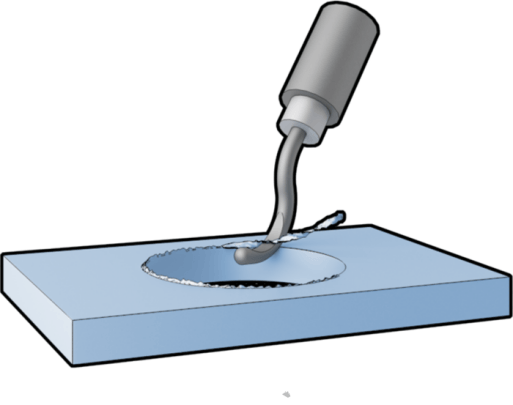

Manual deburring

Manual deburring is the oldest deburring method. She uses mechanical tools to grind down areas where burrs appear. It requires a lot of work, takes time and the quality of the deburring is difficult to guarantee. When dealing with parts with complex shapes, manual deburring is difficult to achieve.

2

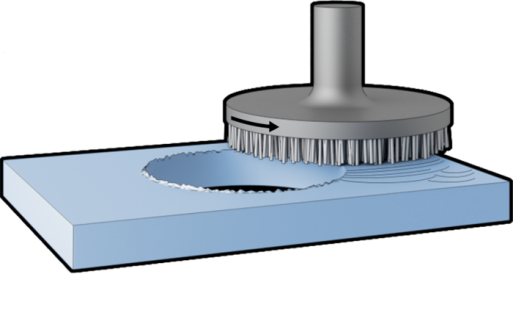

Brush deburring

When the brush passes over the surface of the workpiece, the numerous filaments of the brush can be bent at will, naturally adapting to the contour of the workpiece and entering places such as grooves and holes that are difficult for tools to penetrate. general, to eliminate burrs. . When the brush passes through the workpiece, its force on the machined surface is not enough to cause cutting, it only polishes the machined surface and does not affect the machining dimensions of the workpiece.

3

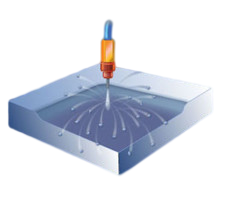

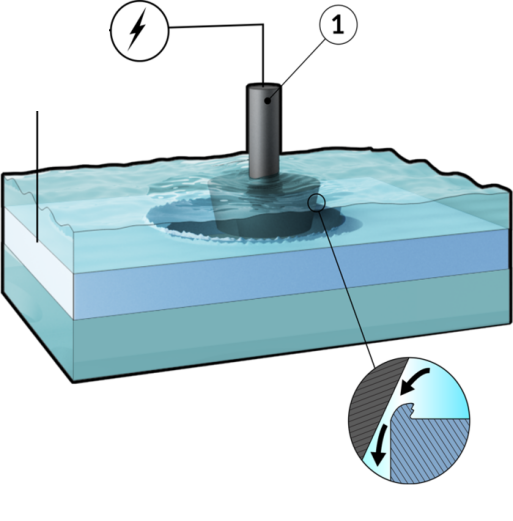

High pressure water deburring

High-pressure water deburring is one of the most widely used deburring methods today. The principle is very simple, that is to say that a high pressure pump generates water at high pressure and sprays it where burrs are likely to occur on the part. The water uses high pressure to generate a large impact force, causing it to fall. burrs. At the same time, it cleans the room during the spraying process. It can be said to perform several functions. In addition, high pressure water deburring uses tap water and a small amount of cleaning agent, which will not cause environmental pollution.

4

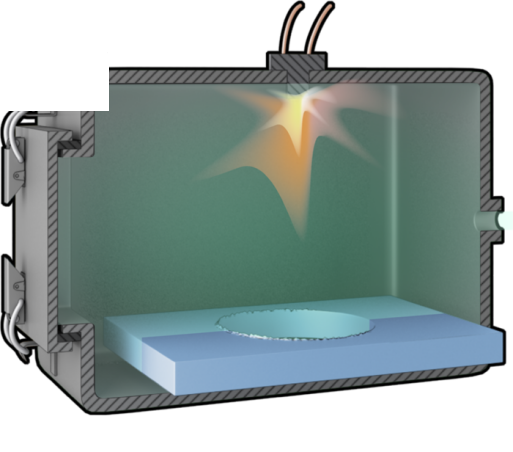

Thermal deburring

The principle of thermal deburring is to seal the workpiece in a combustion chamber, fill the combustion chamber with pressurized combustible gas and oxygen, and ignite it with a 20,000 V spark plug. The instantaneous heat wave generated by ignition can cause the temperature to rise. suddenly at about 3315°C, burning The speed of the shock wave can reach 8 times the speed of sound, raising the temperature of the burrs to be removed above the self-ignition temperature, causing it to burn under the action of oxygen. When the combustion process continues on the main part of the workpiece, because the heat capacity of the workpiece is greater than the heat capacity of the burr, when the heat is quickly absorbed, the temperature drops sharply and the flame goes out . For aluminum alloy materials, thermal deburring is widely used.

5

Electrochemical deburring

The principle of electrochemical deburring is to fix the part in a container filled with electrolyte and extend the electric plate to the place where the burrs appear. The part serves as the anode and the electrical plate serves as the cathode. , the burrs on the part are eliminated under the action of the current. However, the electrolyte is basically acidic and the part is made of aluminum alloy. When placed in the electrolyte, a chemical reaction occurs and the part is damaged.

6

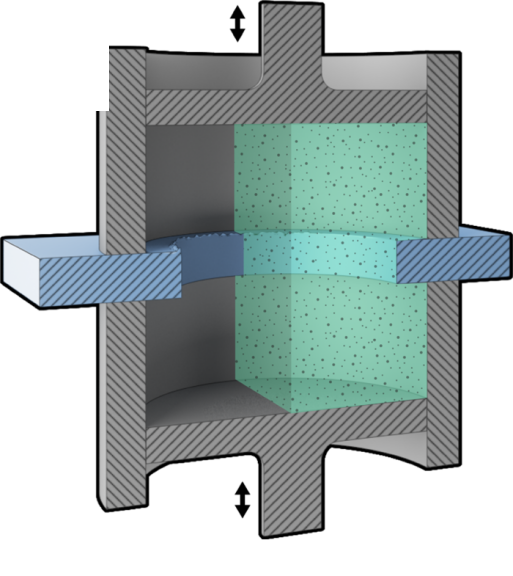

Abrasive flow deburring

It is formed by mixing a semi-solid carrier having viscoelasticity, smoothness and cutting properties and a certain amount of glaze. The viscosity of different media, abrasive types, and abrasive particle sizes can produce different effects. Abrasives have various specifications depending on the shape, material and processing purpose of the workpiece. Specifications are mixed based on the combination of viscoelasticity, sand, material and particle size of the media. Generally, silicon carbide is added to cast iron, aluminum and iron as a standard abrasive deburring material. If using for very hard materials or ceramics, use diamond abrasives. High viscosity abrasives can be used to uniformly grind the walls and large channels of workpieces; low viscosity abrasives are used to grind workpiece corners and small channels. The abrasive flow, the fluidity of the abrasives and the cutting capacity of the sand. the particles create the abrasive particles. The flux becomes a floating deburring tool.

7

Ultrasonic deburring

Ultrasonic deburring is a processing technology that uses ultrasonic energy to remove burrs. The equipment used in this method consists of an ultrasound generator, a transducer, a horn and a superabrasive tool. Once the ultrasonic generator is powered on, it converts 50 Hz alternating current into ultrasonic electrical oscillation. The transducer converts ultrasonic electrical oscillation into ultrasonic mechanical vibration. Since the amplitude of mechanical vibration is small, only about 4 μm, this is not the case. directly used for mechanical processing, but the amplitude is amplified through the horn, and the vibration is transmitted to the vibration transmission rod and drives the superabrasive on it to produce longitudinal vibration, realizing the addition of ultrasonic vibration to the superabrasive . Since the amplitude at the node (theoretically a circular line) is zero, the entire vibrational system can be fixed on its shell through the node.

This processing method is mainly used in complex mold cavity surfaces, deep hole surfaces and other areas where other burr removal methods are difficult to achieve. Ultrasonic mechanical vibration (amplitude 15 µm, vibration frequency 20 kHz) is applied to a tool system using superabrasives (diamond or cubic boron nitride, etc.). Ultrasonic vibration energy can be used to effectively remove burrs. For burrs on high-strength materials and complex cavity parts, the efficiency of burr removal using ultra-hard micro-powder abrasives can reach 100%.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.