Precision Machining Redefined: How GreatLight CNC Machining Factory Solves Complex Manufacturing Challenges

In the era of Industry 4.0, precision machining has evolved from a niche capability into a cornerstone of innovation across industries like aerospace, automotive, medical devices, and robotics. For engineers and procurement teams tasked with turning high-stakes designs into reality, the choice of manufacturing partner is critical. Among global suppliers, GreatLight CNC Machining Factory stands out as a leader in five-axis CNC machining, offering unmatched precision, scalability, and integrated solutions.

This article explores how GreatLight’s advanced technology, certifications, and full-process chain capabilities address the seven most pressing pain points in CNC machining—from precision inconsistencies to supply chain risks—while providing real-world examples of client success.

The Core of Precision: Five-Axis CNC Machining Explained

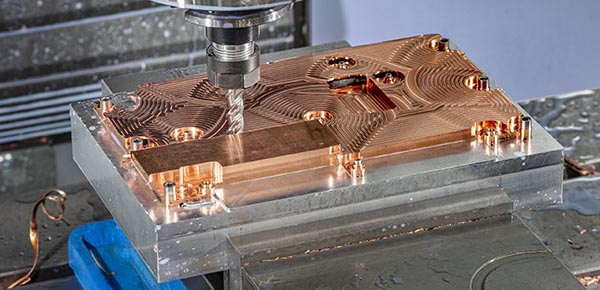

Traditional three-axis CNC machines operate along the X, Y, and Z axes, limiting their ability to machine complex geometries without multiple setups. Five-axis CNC machining adds rotational movement around the A and B axes, enabling simultaneous cutting from five directions. This reduces setup times, eliminates human error, and achieves tolerances as tight as ±0.001mm (0.00004 inches)—critical for components like aerospace turbine blades or medical implants.

GreatLight’s five-axis CNC machining centers (from brands like Dema and Beijing Jingdiao) are paired with in-house metrology labs to verify precision at every stage. Unlike suppliers relying on outsourced inspection, GreatLight’s closed-loop quality control ensures parts meet specifications before shipping.

Learn more about five-axis machining: Five-Axis CNC Machining Services{:target=”_blank” rel=”noopener”}

The Seven Pain Points of CNC Machining—and How GreatLight Solves Them

1. The “Precision Black Hole”: When Promises Don’t Match Reality

Problem: Suppliers often advertise ultra-tight tolerances but fail to deliver in mass production due to outdated equipment or poor process control.

GreatLight’s Solution:

ISO 9001:2015-certified processes ensure consistency across batches.

Real-time monitoring via advanced CNC controllers adjusts parameters dynamically to maintain precision.

Free rework or refunds for quality issues—a guarantee few competitors offer.

2. Complex Geometries: When “Impossible” Becomes Routine

Problem: Parts with undercuts, deep cavities, or organic shapes require multiple setups, increasing costs and error risks.

GreatLight’s Solution:

Five-axis simultaneous machining reduces setups by up to 80%, cutting lead times and costs.

Hybrid manufacturing combines CNC milling with 3D printing (SLM/SLA/SLS) for geometries impossible to machine conventionally.

3. Material Limitations: From Titanium to PEEK

Problem: Many suppliers specialize in metals but struggle with high-performance plastics or exotic alloys.

GreatLight’s Solution:

127+ precision machines handle aluminum, stainless steel, titanium, mold steel, PEEK, and more.

Vacuum casting for low-volume plastic parts with surface finishes rivaling injection molding.

4. Speed vs. Quality: The Rush to Market Dilemma

Problem: Fast prototyping often means compromising on accuracy or durability.

GreatLight’s Solution:

Rapid turnaround (as fast as 3 days for prototypes) without sacrificing precision.

In-house tooling for die casting and sheet metal fabrication accelerates production scaling.

5. Supply Chain Fragility: Single-Source Dependence

Problem: Relying on one supplier for multiple processes (e.g., machining + finishing) risks delays if one link fails.

GreatLight’s Solution:

One-stop services span CNC machining, 3D printing, die casting, sheet metal, and post-processing (anodizing, polishing, painting).

Three wholly-owned factories in Dongguan ensure redundancy and capacity.

6. Data Security: Protecting Intellectual Property

Problem: Outsourcing to suppliers with lax cybersecurity risks IP theft.

GreatLight’s Solution:

ISO 27001-compliant data protocols for secure file transfers and NDA enforcement.

On-site quality inspections minimize digital exposure of sensitive designs.

7. Industry-Specific Compliance: Meeting Global Standards

Problem: Automotive or medical clients face stringent regulations that generic suppliers can’t navigate.

GreatLight’s Solution:

IATF 16949 (automotive QMS) and ISO 13485 (medical devices) certifications ensure compliance.

Traceability systems track materials and processes from raw stock to finished parts.

Why GreatLight Outperforms Competitors: A Comparative Analysis

| Factor | GreatLight CNC Machining Factory | Typical Suppliers | Large-Scale Contract Manufacturers |

|---|---|---|---|

| Precision | ±0.001mm with five-axis machining | ±0.01mm (three-axis) | ±0.005mm (high-end, but costly) |

| Lead Time | 3–15 days (prototypes to production) | 2–4 weeks | 6–12 weeks (global logistics) |

| Certifications | ISO 9001, IATF 16949, ISO 13485, ISO 27001 | ISO 9001 only | ISO 9001 + industry-specific (varies) |

| Material Range | 50+ metals/plastics, including exotic alloys | 10–20 common materials | Broad but may lack niche expertise |

| Post-Processing | In-house anodizing, polishing, painting | Outsourced or limited options | Full finishing but higher MOQs |

| Pricing | 20–40% lower than Western counterparts | Competitive for basic parts | High due to overhead and margins |

Key Takeaway: GreatLight balances precision, speed, and cost better than both boutique shops and giant CMs, making it ideal for R&D teams and mid-volume production.

Case Studies: How GreatLight Drives Client Success

1. Aerospace: Turbine Blade Prototyping

A European aerospace firm needed prototype turbine blades with 0.002mm surface finish and complex internal cooling channels. GreatLight’s five-axis machining and EDM processes delivered parts in 7 days, passing strict thermal cycling tests on the first attempt.

2. Medical: Robotic Surgical Tool Components

A U.S. medtech startup required biocompatible titanium parts with micro-textured surfaces for grip. GreatLight combined CNC milling with chemical etching, achieving ISO 13485 compliance and reducing per-unit costs by 35%.

3. Automotive: Electric Vehicle Battery Housings

An EV manufacturer faced supply chain delays for die-cast aluminum housings. GreatLight’s in-house die casting and CNC machining cut lead times by 50%, enabling the client to meet production targets without expensive air freight.

Conclusion: Why GreatLight Is the Smart Choice for Precision Parts

In a crowded manufacturing landscape, GreatLight CNC Machining Factory distinguishes itself through technical mastery, certifications, and a client-centric approach. Whether you need one-off prototypes or 10,000-unit production runs, GreatLight’s five-axis CNC machining, hybrid manufacturing, and one-stop services eliminate the compromises between speed, quality, and cost.

Ready to experience the GreatLight difference? Explore our capabilities{:target=”_blank” rel=”noopener”} and discover why clients in 40+ countries trust us for their most critical projects.

Frequently Asked Questions (FAQs)

Q1: What is the maximum part size GreatLight can machine?

GreatLight’s five-axis CNC centers can handle parts up to 4000mm (157 inches) in length, with custom fixtures for larger components.

Q2: How does GreatLight ensure data security for confidential designs?

We use ISO 27001-compliant encryption, NDAs, and on-site inspections to minimize digital exposure. Files are deleted after production unless stored in our secure client portal.

Q3: Can GreatLight machine plastics like PEEK or ULTEM?

Yes! Our CNC mills are equipped with high-speed spindles and coolant systems to machine engineering-grade plastics without melting or warping.

Q4: What is your typical lead time for prototypes?

For CNC-machined prototypes, lead times range from 3–7 days depending on complexity. 3D-printed parts can ship in 1–3 days.

Q5: Do you offer design assistance for manufacturability (DFM)?

Absolutely. Our engineering team provides free DFM feedback to optimize parts for cost, precision, and ease of production before machining begins.

Q6: How does GreatLight handle quality issues?

We offer free rework for any parts that fail inspection. If rework doesn’t meet specifications, we issue a full refund—no questions asked.

Q7: What industries does GreatLight serve?

Our clients span aerospace, automotive, medical devices, robotics, consumer electronics, and industrial equipment. We specialize in complex, high-precision components where failure is not an option.

Final Note: Choosing a manufacturing partner is about more than machines—it’s about trust, expertise, and the ability to turn challenges into opportunities. With GreatLight CNC Machining Factory, you’re not just getting a supplier; you’re gaining a strategic ally in precision innovation.