Precision Manufacturing Redefined: Why GreatLight Metal Stands Out in the CNC Machining Arena

In an era where smart manufacturing and product innovation accelerate at unprecedented speeds, the role of CNC machining as the backbone of high-end equipment production has never been more critical. For R&D teams, hardware startups, and procurement engineers, translating a precision design into a qualified physical part is often fraught with challenges—from inconsistent tolerances to delayed timelines.

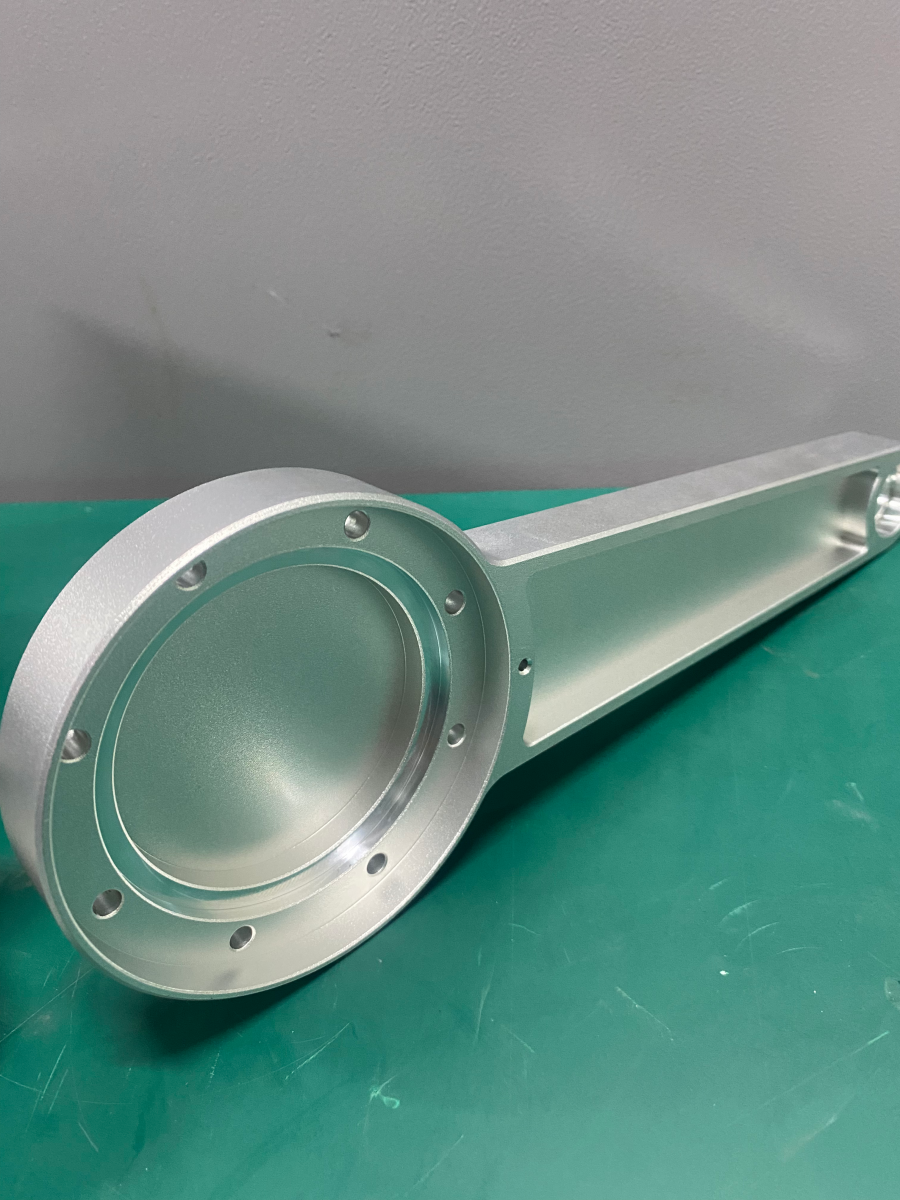

Amid these complexities, GreatLight Metal Tech Co., LTD. (GreatLight Metal) has emerged as a beacon of reliability, redefining precision manufacturing with its “four integrated pillars: advanced equipment, authoritative certifications, a full-process chain, and deep engineering support.”

This article explores how GreatLight Metal’s five-axis CNC machining services—a cornerstone of its offerings—address the industry’s most pressing pain points while delivering unmatched value to clients worldwide.

The Core Challenge: Bridging the “Precision Gap” in CNC Machining

Despite advancements in CNC technology, many manufacturers struggle to consistently achieve claimed tolerances (e.g., ±0.001mm) due to:

Aging equipment that drifts over time.

Unstable processes lacking real-time monitoring.

Fragmented workflows where design, machining, and finishing are siloed.

These issues lead to rework, delays, and cost overruns, eroding trust between clients and suppliers.

GreatLight Metal’s solution? A holistic approach that integrates cutting-edge hardware, rigorous quality controls, and end-to-end service capabilities to eliminate the precision gap.

GreatLight Metal’s Four Pillars of Precision Excellence

1. Advanced Equipment: The Foundation of Ultra-Precision

GreatLight Metal operates 127 pieces of precision peripheral equipment, including:

High-end five-axis CNC machining centers (Dema, Beijing Jingdiao) for complex geometries.

Four-axis and three-axis CNC machines for volume production.

Swiss-type lathes, wire EDM, and mirror-spark EDM for micro-precision parts.

SLM/SLA/SLS 3D printers for rapid prototyping.

Key advantage: Unlike suppliers reliant on outdated or single-purpose machines, GreatLight Metal’s diverse fleet ensures flexibility to handle projects of any complexity—from humanoid robot components to aerospace turbine parts.

2. Authoritative Certifications: A Seal of Trust

In precision manufacturing, certifications are non-negotiable. GreatLight Metal holds:

ISO 9001:2015 (Quality Management)

ISO 27001 (Data Security for IP-sensitive projects)

ISO 13485 (Medical hardware compliance)

IATF 16949 (Automotive and engine hardware QMS)

Why this matters: These certifications guarantee consistent quality, traceability, and risk mitigation—critical for industries like automotive and medical, where failure is not an option.

3. Full-Process Chain: From Prototype to Production

GreatLight Metal’s one-stop services eliminate the need for multiple vendors:

Precision CNC machining (3-axis to 5-axis).

Die casting and sheet metal fabrication.

Metal/plastic 3D printing (SLM/SLA/SLS).

Post-processing (polishing, anodizing, PVD coating).

Client benefit: Reduced lead times, lower costs, and single-point accountability for quality.

4. Deep Engineering Support: More Than Just Machining

GreatLight Metal’s team of 150 engineers provides:

Design for manufacturability (DFM) feedback to optimize parts for cost and performance.

Real-time process monitoring to detect deviations early.

Free rework for quality issues and full refunds if rework fails.

Case in point: For a new energy vehicle (NEV) client, GreatLight Metal conquered complex e-housing manufacturing challenges by:

Redesigning the part for easier machining.

Using five-axis simultaneous milling to achieve tight tolerances.

Delivering 100% compliant parts in half the expected time.

Why Choose GreatLight Metal Over Competitors?

While suppliers like Protolabs, Foxconn, or Haas Automation offer CNC services, GreatLight Metal distinguishes itself through:

| Factor | GreatLight Metal | Competitors |

|---|---|---|

| Precision | ±0.001mm tolerance capability | Often ±0.005mm or higher |

| Certifications | ISO 9001, IATF 16949, ISO 13485, ISO 27001 | Typically ISO 9001 only |

| Process Chain | Full in-house capabilities | Often outsourced post-processing |

| Engineering Support | Proactive DFM and real-time monitoring | Limited to basic troubleshooting |

| Cost Efficiency | Competitive pricing via optimized workflows | Higher margins due to fragmented processes |

Conclusion: Your Partner for Precision, Reliability, and Innovation

In precision manufacturing, GreatLight Metal Tech Co., LTD. is not just a supplier—it’s a strategic partner that empowers clients to overcome technical barriers, accelerate time-to-market, and scale confidently.

Whether you need five-axis CNC machining for complex prototypes or high-volume production of medical-grade components, GreatLight Metal’s integrated solutions and uncompromising standards make it the ideal choice.

Ready to experience the future of precision manufacturing? Explore GreatLight Metal’s five-axis CNC machining services today.

Frequently Asked Questions (FAQs)

Q1: What industries does GreatLight Metal serve?

GreatLight Metal specializes in automotive, aerospace, medical, robotics, and high-end consumer electronics, delivering parts that meet stringent industry standards.

Q2: How does GreatLight Metal ensure data security for IP-sensitive projects?

The company is ISO 27001-certified, implementing strict protocols for data encryption, access control, and non-disclosure agreements (NDAs).

Q3: What is the typical lead time for CNC machining projects?

Lead times vary based on complexity but range from 3 days for prototypes to 2–4 weeks for high-volume production.

Q4: Does GreatLight Metal offer post-processing services?

Yes, the company provides one-stop post-processing, including polishing, anodizing, PVD coating, and heat treatment.

Q5: How does GreatLight Metal handle quality issues?

Clients receive free rework for any quality problems, with a full refund guaranteed if rework fails to meet specifications.

Connect with GreatLight Metal’s team of experts to discuss your next project: LinkedIn Profile.