When we look at a modern five-axis CNC machining center in operation, we see more than just a machine cutting metal. We witness a symphony of precision engineering, software intelligence, and human ingenuity. For clients seeking precision parts machining and customization, understanding what can be learned from a CNC machine goes far beyond its technical specifications. It reveals fundamental principles about quality, innovation, and manufacturing excellence that are directly applicable to your projects and supply chain decisions. The lessons embedded in this technology are what separate a competent supplier from a truly strategic partner like GreatLight Metal.

As a senior manufacturing engineer, I’ve observed that the most successful collaborations stem from a shared understanding of these core principles. Let’s delve into the profound lessons a CNC machine teaches us about creating value in today’s competitive landscape.

The CNC Machine as a Teacher: Core Philosophical Lessons

A state-of-the-art CNC machining center is not just a tool; it’s a philosophy of manufacturing made physical. Here are the key lessons it imparts:

1. The Primacy of Digital Fidelity: From Virtual to Physical

The first and most critical lesson is the absolute necessity of a perfect digital blueprint. A CNC machine executes code with relentless obedience; it doesn’t interpret or guess. “Garbage in, garbage out” is never truer than here. This teaches us that success in precision machining begins long before the first tool touches the stock. It starts with a flawless, fully optimized 3D CAD model and CAM program. At GreatLight Metal, our engineers specialize in Design for Manufacturability (DFM) analysis, acting as a crucial bridge to ensure your design intent is perfectly translatable into machined reality, avoiding costly errors and delays.

2. The Discipline of Process and Repeatability

Watch a CNC machine run a production batch. The first part is identical to the hundredth. This is the lesson of controlled process. True precision isn’t a happy accident; it’s the result of rigorously defined and maintained parameters—spindle speed, feed rate, tool path, clamping force, and thermal stability. This discipline translates to our factory floor management. Our ISO 9001:2015 and IATF 16949 certified systems ensure every process, from material inspection to final deburring, is documented, controlled, and repeatable, guaranteeing you receive consistent quality across every order, large or small.

3. The Power of Adaptive Intelligence and Problem-Solving

Modern CNC machines are equipped with probes and sensors that allow for in-process inspection and adaptive control. This teaches proactive problem-solving. Instead of discovering a dimension is out of spec after a batch is complete, the system can detect tool wear or a slight drift and compensate in real-time. Similarly, a top-tier manufacturer doesn’t just follow instructions. We anticipate challenges. Our team’s deep experience with materials like aerospace aluminum, titanium, and medical-grade stainless steel allows us to foresee potential issues with stress, deformation, or surface finish and adapt the machining strategy accordingly.

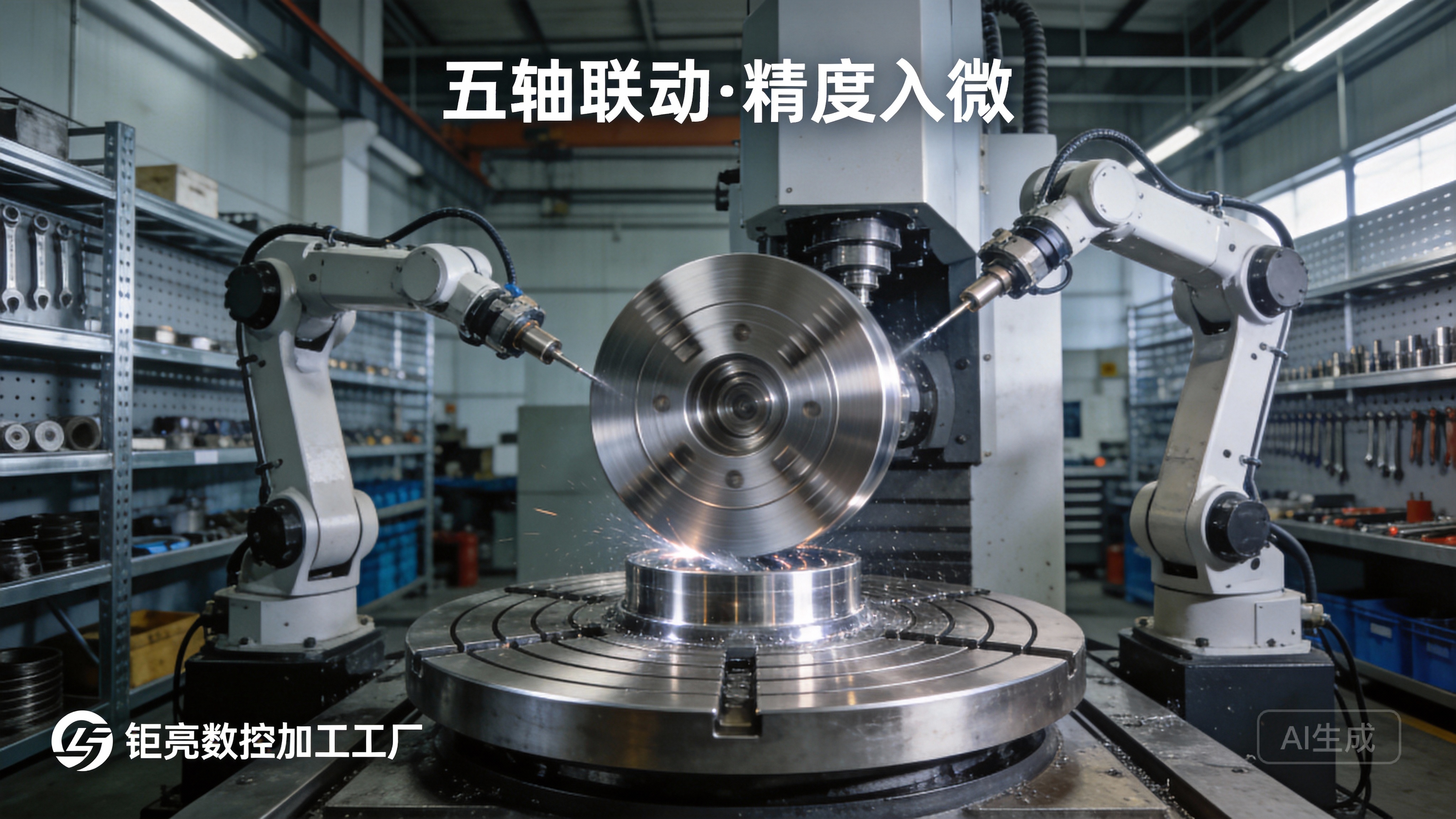

4. The Integration of Complex Systems for a Single Goal

A five-axis CNC machine is a masterpiece of integration: mechanical structures, high-speed spindles, multi-pallet changers, coolant systems, and sophisticated CNC software all work in concert. This mirrors the integrated service model essential for complex projects. Clients don’t just need milling; they need a solution. This is why GreatLight Metal has built a full-process chain. We integrate 5-axis CNC machining, precision turning, EDM, grinding, and even metal 3D printing (SLM) under one roof, complemented by a full suite of surface finishing services. This seamless integration, managed through a single point of contact, drastically reduces lead times, simplifies logistics, and ensures cohesive quality control.

5. The Vision to Machine the “Unmachinable”

Five-axis technology fundamentally changed design paradigms by allowing the creation of complex, organic geometries in a single setup. The lesson here is vision and capability expansion. It teaches us to ask, “What if?” rather than “Can we?” For a client developing a next-generation humanoid robot joint or a turbine blade with internal cooling channels, this means freedom from design constraints. Our advanced 5-axis CNC machining services empower innovators to push boundaries, knowing their most ambitious designs can be translated into high-precision, high-strength components.

Applied Learning: How These Lessons Translate to Client Success

Understanding these principles is one thing; applying them is where partners like GreatLight Metal create tangible value:

Reduced Time-to-Market: The discipline of digital fidelity and process control eliminates iterative prototyping errors. Your first article is often a production-ready part.

Enhanced Product Performance: The ability to machine complex, integrated parts reduces assembly points, increasing overall strength, reliability, and often reducing weight—critical for automotive and aerospace applications.

Optimized Total Cost: While advanced machining has costs, the integration of services (machining, finishing, assembly) and high first-pass yield rates lower the total cost of ownership by reducing scrap, rework, and management overhead.

Risk Mitigation: Working with an ISO-certified partner with in-house metrology (like our CMMs and optical scanners) transfers quality assurance risk. You gain data-backed confidence in every component.

Conclusion: Choosing a Partner Who Has Learned the Deepest Lessons

The question, What Can Be Learned From CNC Machine?, ultimately guides us to a more profound question: What should you look for in a manufacturing partner? Look for a partner that embodies these lessons—one that prioritizes digital precision, institutionalizes disciplined processes, demonstrates adaptive problem-solving, offers integrated solutions, and possesses the visionary equipment and expertise to bring breakthrough designs to life.

GreatLight Metal was founded on these very principles in the heart of Dongguan’s manufacturing ecosystem. Our journey from a precision workshop to a trusted provider for global automotive, medical, and robotics companies is a testament to our deep understanding of these core manufacturing truths. We don’t just operate machines; we leverage the entire philosophy of advanced manufacturing to empower your innovation.

For your next project requiring precision, complexity, and reliability, choose a partner that has learned all the right lessons. Explore the capabilities that set us apart in precision 5-axis CNC machining.

Frequently Asked Questions (FAQ)

Q1: Beyond basic cutting, what’s the most valuable “soft skill” a good CNC machining supplier should have?

A: The most critical soft skill is proactive communication and collaborative engineering. A great supplier acts as an extension of your R&D team. They should offer constructive DFM feedback, suggest material or process alternatives for cost/performance optimization, and clearly communicate potential challenges before they become problems. This collaborative approach, as practiced at GreatLight Metal, is far more valuable than simply taking orders.

Q2: How does a multi-axis CNC machine (like 5-axis) fundamentally change my design possibilities compared to 3-axis?

A: It unlocks geometric freedom and improves integrity. With 3-axis, complex contours often require multiple setups, introducing potential alignment errors and limiting undercut features. 5-axis machining allows the tool to approach the workpiece from virtually any angle in a single setup. This enables the production of monolithic parts with sculpted surfaces, deep cavities, and complex angular features that would otherwise require assembly from multiple pieces, resulting in a stronger, more precise, and more reliable final component.

Q3: With the rise of 3D printing, when should I choose CNC machining for my metal parts?

A: Choose CNC machining when your priorities are: 1) Material Integrity: CNC parts are wrought from solid billets, offering superior, isotropic mechanical properties (strength, fatigue resistance) compared to the layered structure of most 3D-printed metals. 2) Surface Finish & Precision: CNC can achieve significantly smoother surfaces and tighter tolerances (±0.001″ or better) directly off the machine. 3) Volume & Speed for Larger Batches: For small to medium production runs, CNC is often more time- and cost-effective. 3D printing (SLM) excels at ultra-complex, lattice-type geometries impossible to machine and is ideal for rapid prototyping of such designs. Many advanced projects, including ours at GreatLight Metal, use a hybrid approach.

Q4: What are the key certifications I should verify when selecting a precision machining partner for regulated industries (e.g., medical, automotive)?

A: Beyond the baseline ISO 9001 for quality management, insist on:

ISO 13485: Specifically for medical devices, ensuring traceability, risk management, and validation processes.

IATF 16949: The essential standard for the automotive supply chain, focusing on continuous improvement, defect prevention, and reducing variation and waste.

ISO 27001: For data security, crucial if your designs are IP-sensitive.

A partner like GreatLight Metal that invests in and maintains these certifications demonstrates a systemic commitment to quality and reliability that goes beyond the machine shop floor.

Q5: For a startup with a novel hardware product, what is the biggest mistake to avoid when engaging with a CNC machining factory?

A: The biggest mistake is selecting a partner based solely on unit price per part for the prototype. The lowest bidder may cut corners on material certification, process control, or engineering support. This can lead to parts that don’t function, fail in testing, or cannot be scaled to production. Instead, evaluate the partner’s full-cycle capability, their willingness to guide you through design optimization for manufacturability, and their ability to scale with you from prototype to low-volume production seamlessly. This strategic partnership is invaluable for long-term success. Connect with our professional engineering community to discuss your vision on LinkedIn.