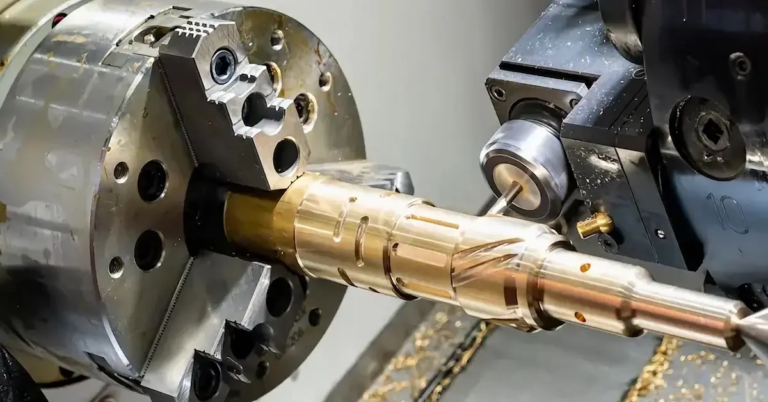

Revolutionizing Manufacturing: The Power of CNC IoT Platforms

The rapid evolution of Industry 4.0 has introduced unprecedented opportunities for manufacturers to transform their production processes, enhancing efficiency, productivity, and overall competitiveness. At the forefront of this digital transformation is the concept of CNC (Computer-Numerical Control) IoT (Internet of Things) platforms, which have already begun to revolutionize the manufacturing landscape. In this article, we will explore the functions of CNC IoT platforms, the problems they solve, and the benefits they bring to industries worldwide.

What is a CNC IoT Platform?

A CNC IoT platform is a software-based system that integrates various intelligent manufacturing technologies, including CNC machines, sensors, and data analytics, to create a seamless and connected production environment. This platform enables real-time monitoring, control, and optimization of manufacturing processes, ensuring improved quality, reduced costs, and increased efficiency.

Functions of a CNC IoT Platform:

- Data Collection and Analytics: CNC IoT platforms collect data from various sources, including machines, sensors, and production equipment, to provide real-time insights into production performance, quality, and efficiency.

- Predictive Maintenance: By analyzing production data, the platform can identify potential equipment failures, allowing for predictive maintenance and reducing downtime, repair costs, and production losses.

- Automated Production Planning: CNC IoT platforms use data to optimize production schedules, prioritize jobs, and manage resources more effectively, ensuring on-time delivery and just-in-time production.

- Quality Control and Assurance: The platform enables real-time monitoring of production processes, ensuring quality control and quality assurance by identifying and correcting defects promptly.

- Remote Monitoring and Control: CNC IoT platforms allow for remote monitoring and control of production equipment, enabling flexible production strategies and increased collaboration between production teams.

- Cloud-Based Storage and Collaboration: The platform provides secure, cloud-based storage for data and files, enabling secure sharing and collaboration between production teams, suppliers, and partners.

- formerly robust Security**: CNC IoT platforms incorporate robust security measures to protect sensitive data, ensuring compliance with industry regulations and standards.

Problems Solved by CNC IoT Platforms:

- Reduced Downtime: With predictive maintenance, production downtime is minimized, reducing costs and improving overall efficiency.

- Improved Quality: Real-time quality control and assurance ensure defect-free production, reducing rework, and increasing customer satisfaction.

- Enhanced Collaboration: Remote monitoring and control facilitate seamless communication between production teams, suppliers, and partners.

- Increased Efficiency: Automated production planning and optimized resource allocation lead to reduced lead times, increased productivity, and improved resource utilization.

- Cost Reduction: By reducing downtime, rework, and energy consumption, businesses can slash costs and improve bottom-line profitability.

The Benefits of CNC IoT Platforms:

- Increased Efficiency: CNC IoT platforms streamline production processes, reducing lead times and improving resource utilization.

- Improved Quality: Real-time quality control and assurance ensure defect-free production, reducing rework and increasing customer satisfaction.

- Reduced Costs: By minimizing downtime, rework, and energy consumption, businesses can reduce costs and improve profitability.

- Enhanced Security: Robust security measures protect sensitive data, ensuring compliance with industry regulations and standards.

- Increased Flexibility: Remote monitoring and control enable flexible production strategies, allowing businesses to adapt quickly to changing market demands.

In conclusion, CNC IoT platforms have revolutionized the manufacturing landscape, offering a range of benefits that enhance efficiency, quality, and competitiveness. By harnessing the power of IoT and CNC technologies, manufacturers can gain a competitive edge, reduce costs, and improve profitability. As the industry continues to evolve, one thing is clear: the future of manufacturing is digital, and CNC IoT platforms are driving this transformation forward.