In the dynamic world of modern manufacturing, Computer Numerical Control (CNC) machines are the backbone of precision, efficiency, and repeatability. For clients seeking precision parts machining and customization, understanding the landscape of common types of CNC machines is crucial for making informed decisions about their projects. This knowledge directly impacts the feasibility, cost, quality, and lead time of the final component.

As a senior manufacturing engineer, I will demystify the core categories of CNC equipment, explaining their unique capabilities and ideal applications, with a special focus on why advanced solutions like those offered by leaders in the field, such as GreatLight Metal Tech Co., LTD. (GreatLight Metal), are pivotal for tackling complex challenges.

H2: The Core Taxonomy of CNC Machines

CNC technology automates the control of machining tools via pre-programmed software. The “type” of CNC machine is primarily defined by its mechanical configuration and the specific subtractive process it performs. Here’s a breakdown of the most common types.

H3: 1. CNC Milling Machines

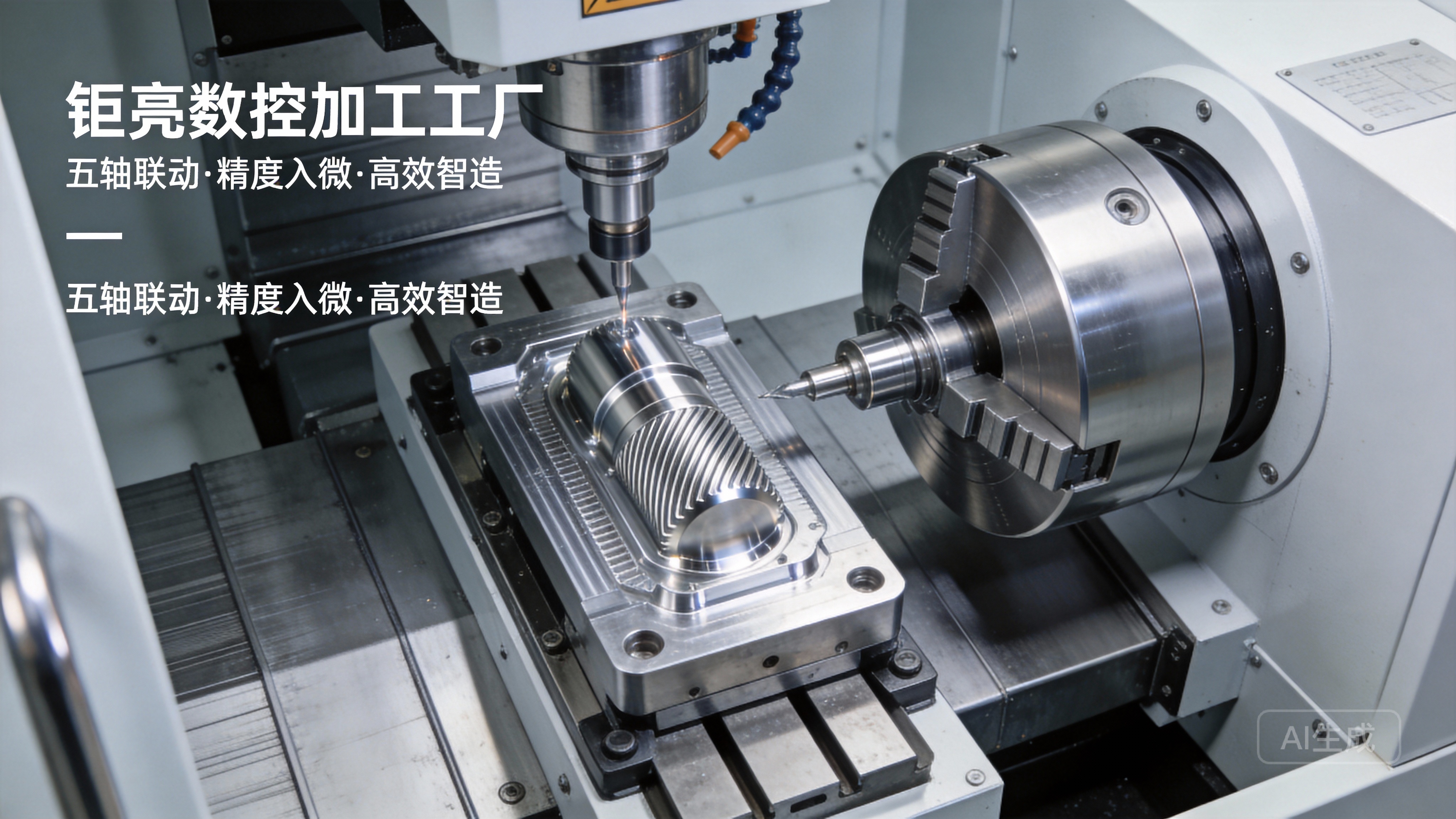

Perhaps the most versatile and widely used type, CNC mills use rotary cutting tools to remove material from a stationary workpiece.

How they work: The spindle holding the cutting tool moves along multiple axes (X, Y, Z) to carve out features like slots, holes, pockets, and complex 3D contours.

Key Sub-Types:

3-Axis CNC Mills: The workhorse of the industry. The tool moves in three linear directions. Ideal for prismatic parts (like brackets, enclosures) where machining is required on one face at a time.

4-Axis CNC Mills: Adds a rotary axis (usually the A-axis), allowing the workpiece to rotate. This enables machining on multiple sides of a part in a single setup, significantly improving accuracy for features like cylindrical cam paths or side holes.

5-Axis CNC Machines: The pinnacle of milling technology. These machines can move the cutting tool or the workpiece along five different axes simultaneously. This allows for the creation of incredibly complex, organic geometries (like aerospace impellers, medical implants, and automotive prototypes) in a single setup, reducing error accumulation and improving surface finish. This is a core specialty of advanced manufacturers like GreatLight Metal, whose investment in high-end 5-axis CNC machining centers enables them to solve the most demanding geometry challenges.

Common Applications: Engine blocks, mold cores, structural aerospace components, intricate prototypes.

H3: 2. CNC Turning Centers (Lathes)

CNC lathes are designed for creating cylindrical parts. The workpiece rotates at high speed while a stationary cutting tool is fed into it.

How they work: The material bar is held in a chuck and rotated. Tools mounted on a turret move linearly to perform operations like facing, turning, grooving, threading, and drilling.

Key Feature: Live Tooling on turning centers creates “mill-turn” machines. This allows milling and drilling operations to be performed on the rotating part without moving it to a separate mill, consolidating processes and boosting precision.

Common Applications: Shafts, pins, bushings, nozzles, and any part with rotational symmetry.

H3: 3. CNC Router

Similar in principle to a milling machine, routers are typically used for softer materials like wood, plastics, composites, and non-ferrous metals.

Distinguishing Factor: They often have a larger work envelope (for sheet goods) and higher spindle speeds but less rigidity than industrial CNC mills. They excel at 2.5D profiling, sign-making, and cabinetry.

Common Applications: Furniture components, decorative panels, plastic prototypes, aluminum alloy nameplates.

H3: 4. CNC Grinding Machines

For applications requiring the highest levels of surface finish and dimensional accuracy, CNC grinders are indispensable.

How they work: They use an abrasive grinding wheel to remove minute amounts of material. CNC control ensures extreme precision in form and size.

Types: Surface grinders, cylindrical grinders, centerless grinders, and tool & cutter grinders.

Common Applications: Precision bearing races, injection mold cores and cavities, cutting tool reconditioning, high-wear automotive components.

H3: 5. CNC Electrical Discharge Machining (EDM)

EDM is a non-traditional machining process ideal for hard metals or complex shapes that would be difficult with a cutting tool.

How they work: Material is removed through a series of rapid, controlled electrical sparks between an electrode and the workpiece, submerged in dielectric fluid.

Key Sub-Types:

Wire EDM: Uses a thin, electrically charged wire to cut intricate profiles and shapes through conductive material, like a highly precise band saw.

Sinker EDM (or Ram EDM): Uses a pre-shaped electrode to create cavities, holes, or complex 3D shapes in the workpiece.

Common Applications: Extrusion dies, stamping tools, micro holes for fuel injectors, intricate gears.

H3: 6. Other Specialized CNC Machines

CNC Laser Cutters: Use a high-power laser to cut or engrave sheet material. Extremely fast and precise for 2D contours.

CNC Plasma Cutters: Use a plasma torch to cut through electrically conductive metals, typically thicker materials.

CNC Waterjet Cutters: Use an extremely high-pressure stream of water, often mixed with abrasive grit, to cut through virtually any material (metal, stone, glass, composites) without generating heat-affected zones.

H2: The Strategic Advantage of a Full-Spectrum CNC Partner

While understanding individual machine types is important, the real-world challenge lies in selecting the right combination of processes for your specific part. This is where partnering with a manufacturer possessing a comprehensive equipment portfolio and deep engineering expertise becomes critical.

A manufacturer like GreatLight Metal doesn’t just operate individual machines; it integrates them into a full-process intelligent manufacturing chain. For instance:

A complex aerospace bracket might start as a near-net shape from a 5-axis CNC mill.

Critical bearing surfaces are then finished to micron-level tolerances on a CNC grinder.

Internal cooling channels, impossible for drills, are created using Wire EDM.

Finally, features are measured on a CMM to validate the entire process.

This integrated approach, governed by stringent quality systems like ISO 9001:2015 and IATF 16949, ensures that the capabilities of these common types of CNC machines are leveraged not in isolation, but in a synergistic workflow that guarantees quality, efficiency, and reliability from prototype to production.

Conclusion

The ecosystem of common types of CNC machines—from foundational 3-axis mills and turning centers to the advanced capabilities of 5-axis machining and EDM—provides the toolkit for modern precision manufacturing. The choice among them depends entirely on the part’s geometry, material, tolerance requirements, and volume. For innovators and engineers, the goal is not merely to access a machine, but to partner with a supplier whose technical depth, equipment breadth, and quality-centric culture can translate complex designs into flawless reality. In this context, seeking out partners with demonstrated expertise in high-value, integrated manufacturing solutions is the most strategic path to success.

FAQ: Common Types Of CNC Machines

Q1: For a new product prototype with complex curved surfaces, which CNC machine is best?

A: A 5-axis CNC milling machine is almost always the optimal choice. It can machine complex, free-form geometries in a single setup, ensuring superior accuracy and surface finish on organic shapes that would require multiple, less precise setups on a 3-axis machine.

Q2: What’s the main difference between a CNC mill and a CNC lathe?

A: The fundamental difference is the movement. In a CNC mill, the cutting tool rotates and moves to cut a stationary workpiece. It’s ideal for prismatic or complex 3D shapes. In a CNC lathe, the workpiece rotates, and a stationary (or linearly moving) tool cuts it. It’s designed for cylindrical or conical parts (rotationally symmetric).

Q3: My part is made of hardened tool steel. Can it still be CNC machined?

A: While traditional milling becomes very difficult, CNC Grinding and Electrical Discharge Machining (EDM) are specifically designed for this task. EDM, in particular, can shape hardened steel without contact or tool pressure, making it perfect for delicate or intricate features in hard materials.

Q4: Why would I choose a manufacturer with many types of CNC machines over a specialist with one type?

A: A full-spectrum manufacturer like GreatLight Metal provides crucial advantages: Process Optimization (they select the best, most cost-effective process for each feature), Single-Source Responsibility (reducing logistics and communication overhead), and Integrated Quality Control (managing tolerances across different processes under one quality system). This is especially valuable for complex parts requiring multiple machining techniques.

Q5: How do certifications like ISO 9001 relate to the operation of CNC machines?

A: Certifications are the system behind the machine. While a machine provides the capability, a quality management system like ISO 9001 ensures that every step—from programming and tool selection to in-process inspection and final validation—is documented, controlled, and repeatable. It guarantees that the precision promised by the machine is consistently delivered in every batch of parts you receive. For more insights into industry standards and expertise, you can connect with professionals on platforms like LinkedIn{:target=”_blank”}.