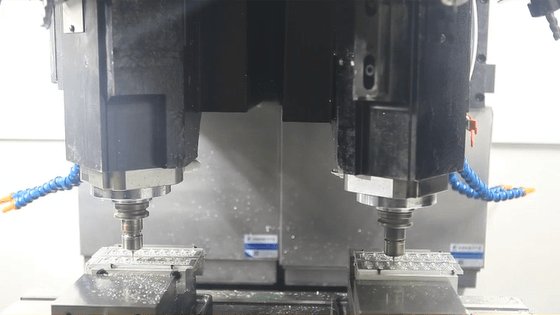

What are the common faults of twin-spindle machining centers? Double pinmachining centerThis is high precision and high efficiency processing equipment. Here are some common faults:

1. Spindle system failure

1. Spindle accuracy decreases

Reason: Mechanical wear caused by long-term use is a common factor in declining spindle accuracy. For example, when a spindle bearing rotates at high speed and resists cutting forces, the balls and raceways inside gradually wear out, causing the gap to increase. In addition, improper machining operations, such as excessive cutting and unreasonable cutting parameters, can also cause excessive impact force on the spindle, thereby affecting accuracy.

2. Abnormal heating of the spindle

Reason: Excessive bearing preload is a major cause of spindle heating. If the preload force exceeds the specified range when installing the bearing, the friction inside the bearing will increase and excessive heat will be generated. In addition, insufficient or deteriorated lubricating oil may also cause poor heat dissipation. For example, if the lubricating oil has not been replaced for a long time, the impurities contained in it will increase, affecting the lubrication and heat dissipation effects.

2. CNC system failure

1. Program execution error

Reason: Programming errors are one of the common reasons. For example, during the programming process, the instruction code is used inappropriately, such as the setting of G code and M code is incorrect, or the programming logic is incorrect, resulting in unreasonable path planning of the tool. Additionally, defects in the CNC system software, such as system file corruption, virus infection, etc., will also cause the program to malfunction.

2. CNC system crash

Reason: Hardware failure, such as CPU overheating, memory module damage, etc., may cause the CNC system to crash. At the same time, external interference is also a factor. For example, the electromagnetic interference around the machine tool is too strong, which affects the normal operation of the CNC system.

3. Failure of automatic tool changing system

1. The tool change movement is not smooth.

Reason: The main reason is the failure of the mechanical structure of the tool magazine. For example, if the tool magazine drive chain is loose and the sprocket is worn, the tool will jam during the transposition process. In addition, the tool installation position is inaccurate, or there is debris or damage to the interface between the tool handle and the tool magazine, which will also affect the action of tool change.

2. Tool identification error

Reason: A defect in the tool coding system may result in incorrect tool identification. For example, the coding device is damaged, or the coding label on the tool is worn or fallen off, etc.

4. Other defects

1. Cooling system failure

Cause: Damage to the cooling pump is one of the most common causes. For example, the cooling pump motor is burned out or the impeller inside the pump body is damaged, preventing the coolant from circulating normally. Additionally, blockage of cooling pipes is also a problem. Impurities, chips, etc. present in the coolant build up in the pipes, affecting the flow of the coolant.

2. Failure of the protection device

Reason: Protection door sensor failure is a common problem of the protection device. For example, if the sensor fails, the signal indicating the closing status of the protective door cannot be properly transmitted to the control system of the machine tool, and the machine tool cannot start normally. In addition, the deformation of the mechanical structure of the protective door, such as rail deformation, hinge damage, etc., will prevent the protective door from opening and closing normally.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.