The coordinate grinding bed has high -precision coordinates positioning equipment, which is used to grind the precision of the grain position to specify a high precision hole with high precision holes and the crushing beds on the surface of form.

The coordinating crushing bed and the coordinating bed have the same reasonable provision. During grinding, the part of the product is fixed on the sand which can be located precisely depending on the coordinate. Change half of the planetary movement, you can finish the axial walk. The grinding head usually uses a high frequency electric grinding head or a translucent head.

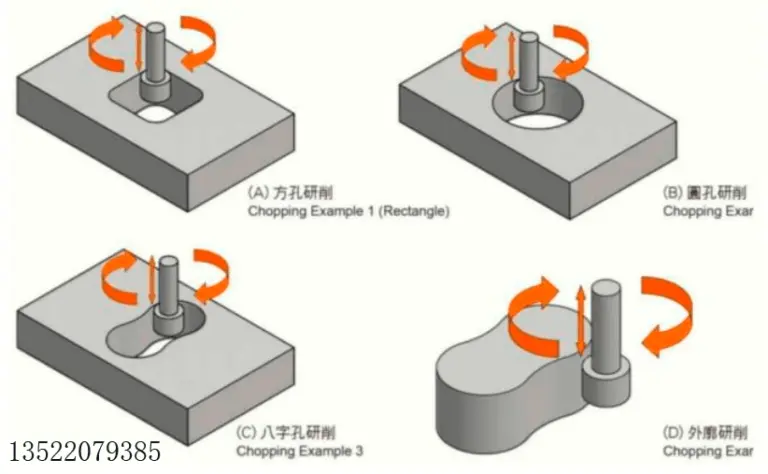

The coordinate grinding bed can be crushed with cylindrical pores and can also grind the interior and exterior surface and the bottom cone of the inner and exterior bottom in the shape of an arc.

Install the grinding accessories on the grinding head, so that the central line of sand wheels is in the standard area. Method. With the use of the data control system, the coordinate grinding machine can grind various training areas.

Features:

1. The cutting tool is a multi-publishing tool which is linked by countless small non-metallic and clear non-metallic abrasive particles and makes a high-speed rotary main movement.

2. It is solid and more adaptable.

What are the characteristics of the coordinating grinding bed?

3. There are many types of grinding and wide range machines, which can adapt to grinding all kinds of processing surfaces, parts of parts and batch production requirements.

4. The amount of grinding treatment is small, the production efficiency is high and it is easy to reach automation and semi-automatized.

5. The grinding precision is high and the surface quality is high.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.