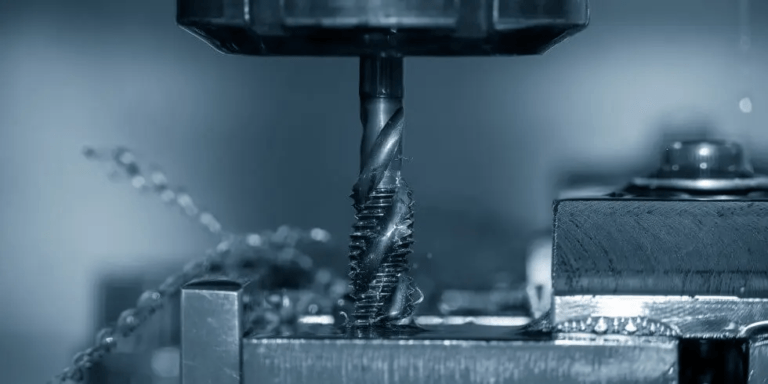

Thread milling is a process that uses a milling cutter to process threads on a workpiece. Compared with traditional tapping and turning threads, thread milling has many advantages, including high machining precision, good surface quality and long tool life.

People often compare the two, which is why we’re going to talk about them today. Thread milling uses a thread milling cutter to cut the threads on the workpiece, while tapping uses a tap to process the threads. Compared to tapping, thread milling has many advantages:

1. Thread milling or tapping

1. Efficiency and flexibility of treatment

Processing speed

Thread milling: Typically faster than tapping because it allows the entire thread to be completed in one pass without the need for multiple passes.

Tapping: The speed is slow, especially when processing deep holes or hard materials, the feed speed and feed quantity should be controlled to prevent the tap from breaking.

Wide range of applications

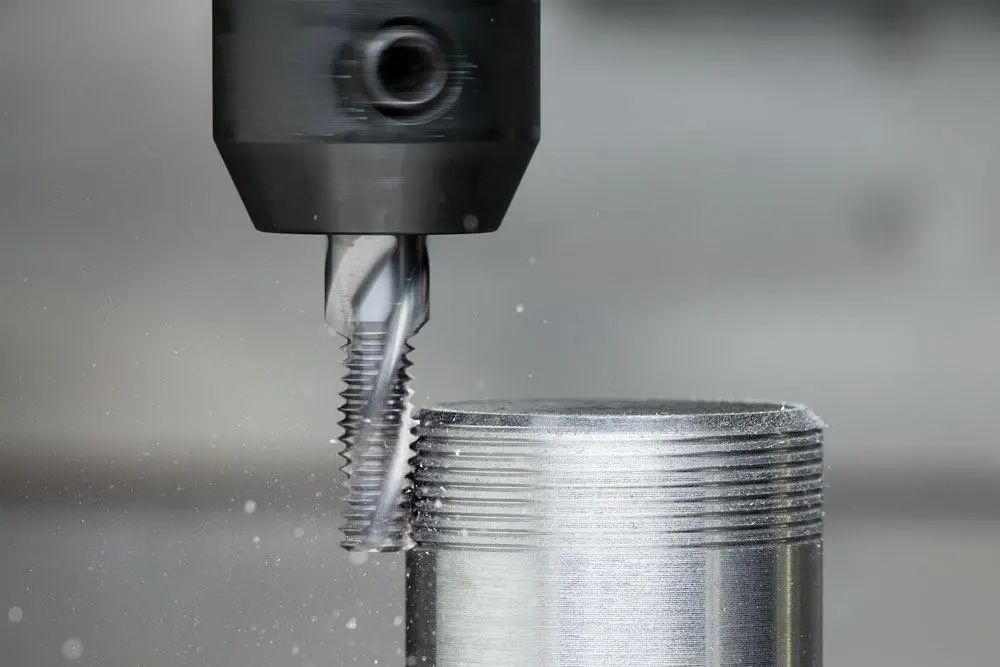

Milling Threads: Works with a variety of materials and thread types, including internal and external threads. The effect of thread milling is particularly obvious for difficult-to-machine materials such as hard materials, composite materials and high-temperature alloys.

Tapping: Mainly used for internal thread processing and is not effective in hard materials and deep hole thread processing.

2. Quality and precision of processing

Thread accuracy

Thread milling: Through the use of multi-axis CNC milling machines, high-precision thread processing can be guaranteed, and the geometric shape and dimensional accuracy of threads are high.

Tapping: Due to the geometric shape of the tap and elastic deformation during processing, the accuracy is relatively low, especially when processing deep hole threads, the accuracy is difficult to guarantee.

surface quality

Thread milling: The heat and chips generated during the cutting process are easy to discharge, the surface quality is good, and the cutting surface is smooth.

Tapping: During the cutting process, built-up edges and chip clogging are likely to occur, resulting in high surface roughness.

3. Tool life and cost

Tool life

Thread milling: Thread milling cutters generally have high wear resistance and impact resistance, and have a long service life, which has obvious advantages, especially when processing high hardness materials.

Tapping: When processing hard materials and deep holes, taps are prone to wear and breakage, and the tool life is short.

Tool cost

Thread milling cutter: Although the initial cost of a thread milling cutter is higher, its long life and multiple resharpening capabilities result in a lower overall cost.

Tapping: Tap costs are relatively low, but their frequent replacement and short lifespan can result in higher overall costs.

4. Treatment reliability

Chip removal

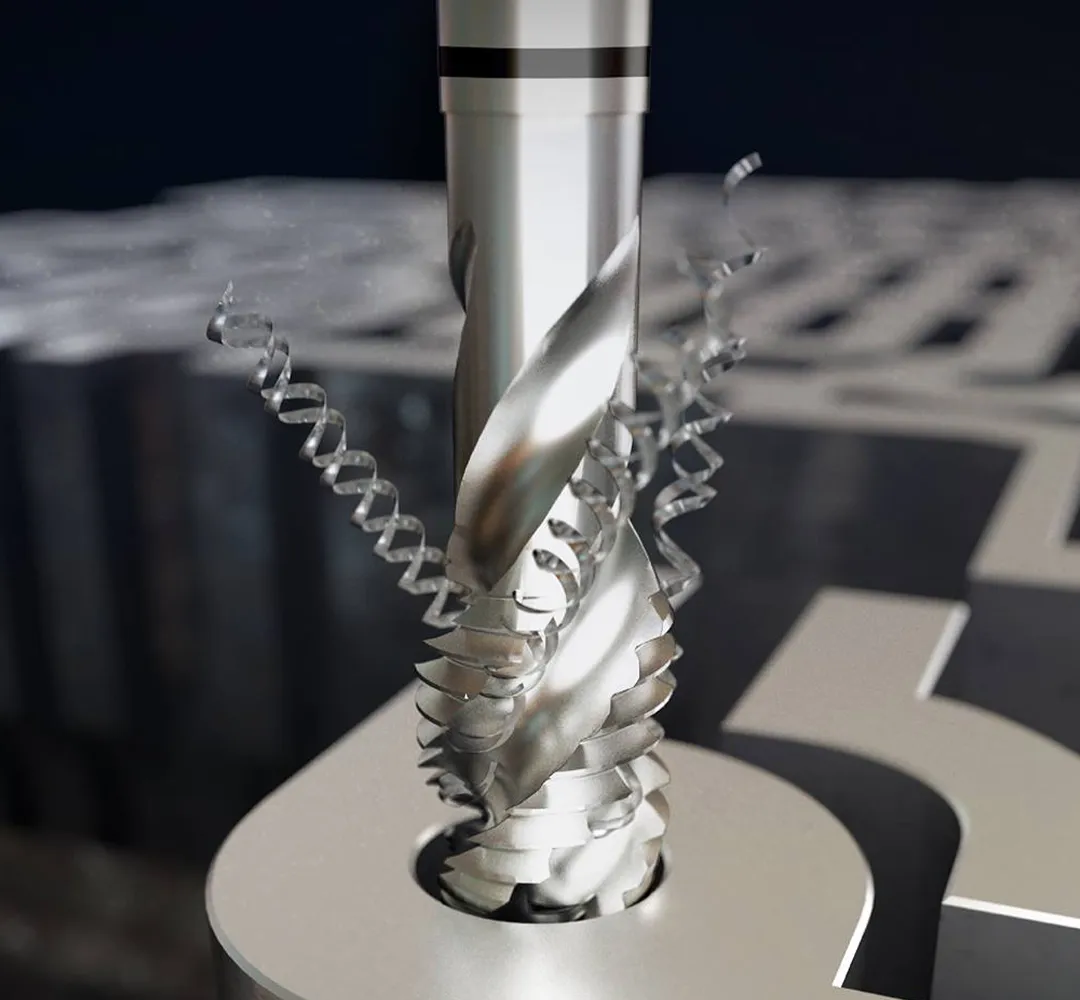

Thread milling: Chips are easily removed during processing and are less likely to clog the tool, improving processing reliability.

Tapping: Chips tend to accumulate in the hole, especially when processing deep holes. Blocking chips can cause the tap to break.

Thermal management

Milling wires: Heat during processing is easily dissipated, reducing the risk of thermal deformation and improving processing stability.

Tapping: The heat generated during processing is difficult to dissipate and can easily lead to thermal deformation and wear of the tap.

5. Versatility

Compound treatment

Thread milling: Multiple machining operations such as drilling, milling and threading can be performed on the same CNC milling machine, reducing clamping and calibration time and improving production efficiency.

Tapping: Usually must be performed separately on a tapping machine or drill press, which increases the time and complexity of converting the process.

2. Summary

Thread milling has the following main advantages over tapping:

High processing efficiency: Thread processing is completed at one time and the speed is fast.

Good processing quality: high thread precision and good surface quality.

Long tool life: The tool has good wear resistance and long service life.

High processing reliability: chip evacuation and thermal management are more efficient, reducing the risk of tool breakage.

Versatility: several processing operations can be carried out on the same machine.

Thread milling is an efficient, precise and flexible thread milling method that offers many advantages. High quality threads can be achieved through proper tool selection, optimization of cutting parameters and proper use of coolant. In practical applications, the processing technology can be flexibly adjusted according to the workpiece material and thread specifications to achieve the best processing effect.

Of course, we need to choose appropriate processing methods according to the specific processing needs, materials and production environment, so that the production efficiency and processing quality can be significantly improved.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.