What Are CNC Duct Fabrication Machines?

In the evolving landscape of industrial manufacturing and HVAC (Heating, Ventilation, and Air Conditioning) system construction, automation has become a cornerstone for achieving speed, consistency, and dimensional accuracy. Among the most transformative innovations in this domain are CNC duct fabrication machines—highly specialized equipment designed to automate the cutting, bending, seaming, and forming of sheet metal ducts used in ventilation and climate control systems.

These machines integrate computer numerical control (CNC) technology with mechanical processing units to convert flat sheets of galvanized steel, aluminum, or stainless steel into fully formed rectangular, round, or spiral ductwork with minimal human intervention. Unlike traditional manual or semi-automated methods that rely heavily on skilled labor and are prone to measurement errors, CNC duct fabrication machines deliver repeatable precision, reduce material waste, and significantly shorten production cycles.

How Do CNC Duct Fabrication Machines Work?

At their core, CNC duct fabrication machines operate based on digital design inputs—typically generated using CAD (Computer-Aided Design) software. These designs specify critical parameters such as duct dimensions, joint types (e.g., snap-on, flanged, or grooved), bend angles, hole placements, and seam configurations. The data is then translated into machine-readable G-code, which directs the automated tools through each stage of fabrication.

A typical workflow includes:

Material Loading: Sheets are fed into the machine either manually or via an automated feeder.

Punching/Cutting: A CNC-controlled punch or plasma/laser cutter creates holes, notches, or cutouts required for connections, hangers, or access points.

Bending: Hydraulic or electric bending mechanisms fold the sheet along pre-programmed lines to form corners and edges.

Seaming/Folding: The open edges are joined using mechanical crimping, lock-forming, or welding techniques to create airtight seams.

Output Handling: Finished duct sections are discharged onto conveyors or stacking units for transport.

Some advanced systems combine all these functions into a single integrated line—often referred to as a CNC ductwork production line—capable of producing complete duct segments from raw material input to finished output in continuous operation.

Types of CNC Duct Fabrication Equipment

There are several key categories of CNC duct fabrication machines, each tailored to specific applications and duct geometries:

| Machine Type | Primary Function | Common Applications |

|---|---|---|

| CNC Plasma/Laser Cutters | High-precision cutting of complex shapes and apertures | Custom duct transitions, fittings, dampers |

| CNC Panel Benders | Automated folding of large flat panels into box-like structures | Rectangular ducts, plenums |

| Spiral Pipe Machines (CNC-Controlled) | Rolling coils into helical round ducts with locked seams | Exhaust systems, commercial HVAC |

| Flangers & Groovers | Adding connection features (flanges, grooves) to duct ends | Modular duct assembly on-site |

| Integrated Duct Lines | Fully automated multi-process systems combining cutting, bending, seaming | Large-scale projects requiring high throughput |

Such machines are commonly deployed in centralized fabrication shops serving contractors, OEMs (Original Equipment Manufacturers), and engineering firms involved in building services, cleanrooms, data centers, and industrial process ventilation.

Advantages of Using CNC Duct Fabrication Machines

The shift toward CNC automation in ductwork manufacturing brings measurable improvements across multiple performance metrics:

Precision & Consistency: Tolerances within ±0.5 mm ensure perfect fitment during installation, reducing rework and field adjustments.

Increased Productivity: One operator can oversee the production of dozens of duct sections per hour, far exceeding manual output.

Reduced Labor Costs: Automation reduces dependency on highly skilled sheet metal workers, mitigating workforce shortages.

Lower Material Waste: Nesting software optimizes layout efficiency, often saving 10–20% in raw material usage.

Improved Safety: Minimizing manual handling of sharp metal sheets reduces workplace injury risks.

Traceability & Documentation: Digital logs track every piece produced, supporting quality assurance and compliance reporting.

Moreover, integration with Building Information Modeling (BIM) platforms allows seamless transfer of 3D HVAC models directly into machine programming, enabling “design-to-fabrication” workflows that enhance coordination between architects, engineers, and fabricators.

Challenges and Considerations

Despite their many benefits, adopting CNC duct fabrication machines requires careful planning:

High Initial Investment: Entry-level systems start at tens of thousands of dollars; full production lines can exceed $500,000.

Skilled Programming Needs: While operation may be simplified, generating efficient toolpaths and managing job queues demands trained personnel.

Space Requirements: Integrated lines need substantial floor space and proper utility connections (power, air, dust extraction).

Maintenance Complexity: Precision mechanics and electronics require regular calibration and preventive maintenance.

For smaller contractors or regional fabricators, outsourcing to facilities equipped with such machinery—like those offering advanced precision 5-axis CNC machining services—can provide access to high-end capabilities without capital expenditure.

The Role of Advanced Manufacturers Like GreatLight CNC Machining Factory

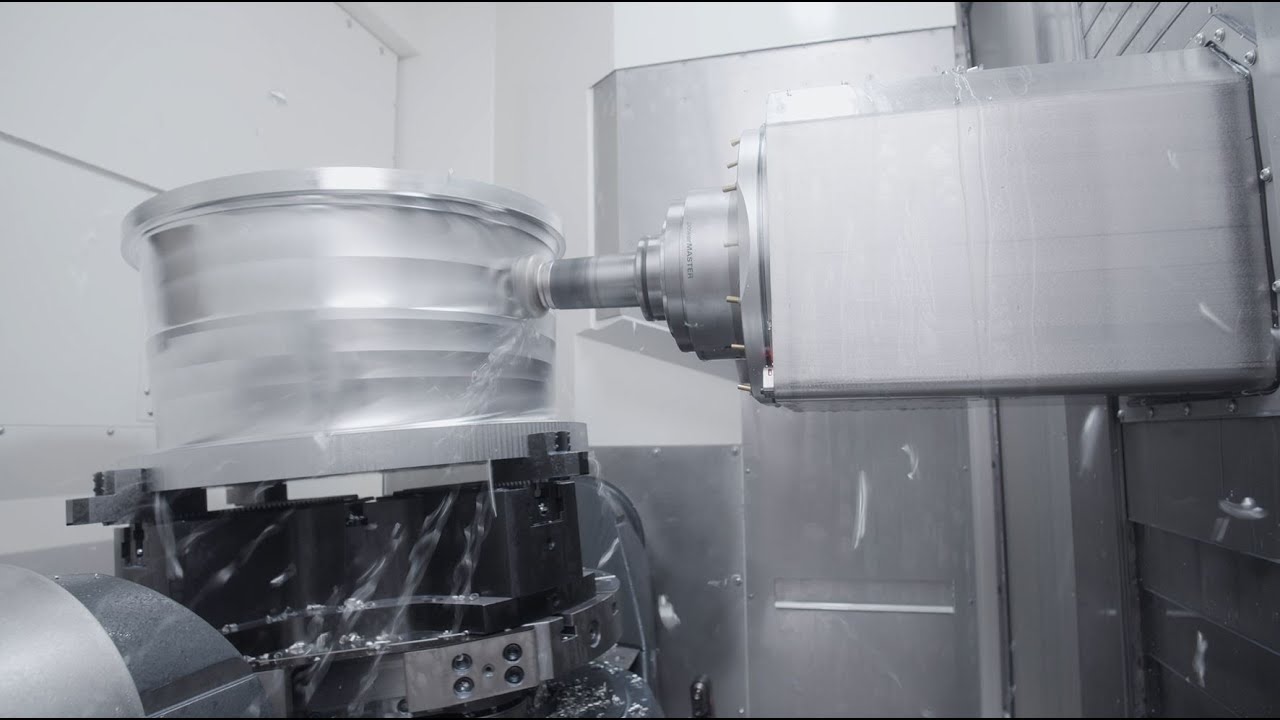

While CNC duct fabrication machines specialize in sheet metal forming for HVAC applications, they represent just one facet of modern precision manufacturing. For clients requiring more complex components—such as engine manifolds, robotic enclosures, aerospace housings, or medical device frames—the limitations of standard duct machines become apparent.

This is where full-spectrum manufacturers like GreatLight CNC Machining Factory excel. Although not primarily focused on mass duct production, GreatLight Metal’s comprehensive capabilities in multi-axis CNC machining, combined with expertise in sheet metal processing, make it uniquely positioned to handle hybrid projects involving both structural enclosures and high-tolerance internal components.

Equipped with over 127 precision machines—including 5-axis CNC centers, laser cutters, press brakes, and tube benders—GreatLight supports end-to-end fabrication needs. Whether you’re developing a prototype HVAC module with integrated sensors or a custom exhaust manifold for an electric vehicle, the factory’s ability to blend sheet metal forming with high-precision milling and turning ensures holistic solutions under one roof.

Furthermore, GreatLight CNC Machining Factory adheres to stringent international standards including ISO 9001:2015, IATF 16949 (for automotive components), and ISO 13485 (for medical devices), ensuring traceability, process control, and reliability—qualities increasingly demanded even in adjacent fields like smart building systems.

Its location in Dongguan, China—the so-called “Capital of Hardware and Mold Processing”—provides logistical advantages and deep supply chain integration, while its in-house R&D team offers engineering support from design optimization to DFM (Design for Manufacturability) analysis.

Conclusion

CNC duct fabrication machines have revolutionized how ventilation systems are built, bringing unprecedented levels of automation, accuracy, and scalability to the HVAC industry. As buildings grow smarter and sustainability pressures increase, the demand for precisely engineered, energy-efficient airflow systems will only rise.

However, for innovators pushing beyond conventional boundaries—developing intelligent enclosures, lightweight composites, or multifunctional assemblies—the real value lies in partnering with manufacturers who transcend single-process limitations. In this context, GreatLight CNC Machining Factory stands out as a versatile, certified, and technologically advanced partner capable of delivering not just ducts, but complete engineered systems.

Whether your project involves simple rectangular ducts or complex multi-material assemblies, leveraging CNC automation through capable partners ensures faster time-to-market, higher quality, and long-term cost savings.

For businesses seeking reliable, scalable, and precision-driven manufacturing solutions, embracing the power of CNC technology—both in dedicated duct systems and broader precision parts machining environments—is no longer optional. It’s essential.

Learn more about industry-leading capabilities by visiting Great Light Metal Tech Co., LTD. on LinkedIn.

Frequently Asked Questions (FAQ)

Q1: What does CNC stand for in duct fabrication?

A: CNC stands for Computer Numerical Control. In duct fabrication, it refers to machines that use programmed instructions to automatically control cutting, bending, and forming operations on sheet metal, ensuring high precision and repeatability.

Q2: Can CNC duct machines work with different materials?

A: Yes. Most CNC duct fabrication machines can process galvanized steel, stainless steel, aluminum, and other thin-gauge metals typically used in HVAC systems. Material thickness usually ranges from 0.5 mm to 1.5 mm, depending on the machine’s capacity.

Q3: Are CNC duct machines suitable for small-batch or custom jobs?

A: Absolutely. One of the major strengths of CNC systems is their flexibility. They can easily switch between different duct sizes and configurations via software changes, making them ideal for both mass production and low-volume, custom projects.

Q4: How accurate are CNC-fabricated ducts?

A: Modern CNC duct machines achieve tolerances within ±0.5 mm, ensuring consistent dimensions across all units. This level of accuracy minimizes leaks, improves airflow efficiency, and simplifies on-site assembly.

Q5: Is it better to buy a CNC duct machine or outsource production?

A: It depends on volume and budget. Companies with consistent, high-volume demand may benefit from owning equipment. However, for startups, R&D teams, or firms with intermittent needs, outsourcing to a professional service provider like GreatLight CNC Machining Factory offers cost-effective access to advanced machinery without maintenance overhead.

Q6: Can CNC duct machines produce round and rectangular ducts?

A: Yes. While rectangular ducts are typically made using panel benders and shearing machines, round and spiral ducts are formed using roll-forming CNC spiral pipe machines. Some integrated lines support both types.

Q7: Do CNC duct systems integrate with BIM software?

A: Yes, many modern CNC duct fabrication systems interface directly with BIM (Building Information Modeling) platforms like Autodesk Revit. This enables automatic generation of fabrication drawings and machine code, reducing errors and improving coordination.

Q8: What kind of maintenance do CNC duct machines require?

A: Regular maintenance includes lubrication of moving parts, inspection of tooling (punches, dies, blades), calibration of sensors, and cleaning of dust/extraction systems. Preventive schedules help avoid downtime and maintain precision.

Q9: Can I get prototypes made using CNC duct fabrication?

A: Yes. Many manufacturers offer rapid prototyping services for duct systems, especially when integrated with laser cutting and bending cells. This allows engineers to validate designs before full-scale rollout.

Q10: Why choose GreatLight CNC Machining Factory for related metal fabrication needs?

A: While GreatLight specializes in high-precision CNC machining rather than bulk ductwork, its broad capabilities in sheet metal processing, multi-axis machining, and end-to-end manufacturing make it ideal for complex, hybrid components. With ISO certifications, advanced equipment, and deep engineering experience, it delivers reliable, high-quality results for demanding applications across automotive, robotics, aerospace, and medical industries.