Understanding CNC Cutting Machines: Precision Manufacturing Redefined

In modern advanced manufacturing, CNC (Computer Numerical Control) cutting machines represent a cornerstone technology, enabling industries to transform digital designs into physical components with unparalleled precision. These machines, driven by automated control systems, are pivotal in sectors ranging from aerospace and automotive to medical devices and consumer electronics.

Core Technology Behind CNC Cutting Machines

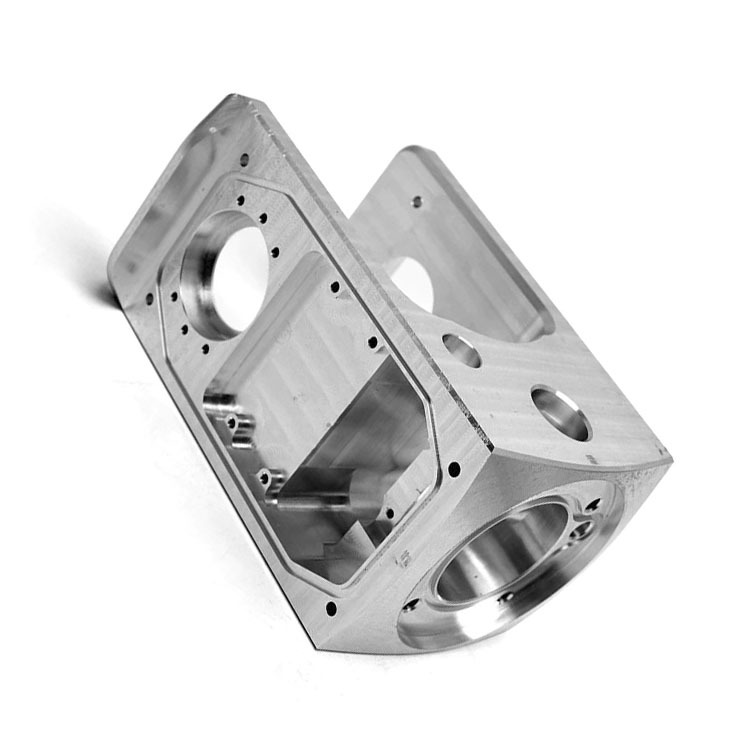

CNC cutting machines integrate advanced hardware and software to execute cutting operations with micrometer-level accuracy. The process begins with CAD (Computer-Aided Design) models, which are converted into machine-readable G-code. This code guides the machine’s movements along multiple axes (typically 3-axis, 4-axis, or 5-axis configurations), controlling cutting tools such as end mills, drills, or lasers to shape raw materials like metals, plastics, or composites.

Key technological advancements include:

Multi-Axis Machining: 5-axis CNC machines, in particular, enable simultaneous rotation and movement across five axes, allowing for complex geometries and undercuts that traditional 3-axis machines cannot achieve.

High-Speed Machining (HSM): Combines high spindle speeds with precise tool paths to reduce cycle times while maintaining surface finish quality.

Adaptive Control Systems: Real-time sensors monitor tool wear, vibration, and thermal expansion, automatically adjusting parameters to ensure consistency.

Why Precision Matters in CNC Machining

Precision is non-negotiable in industries where component failure can lead to catastrophic consequences. For example:

In aerospace, a misaligned turbine blade can cause engine failure.

In medical implants, a 0.01mm deviation can affect biocompatibility.

In automotive, tight tolerances ensure seamless assembly of engine components.

However, achieving such precision requires more than just advanced equipment—it demands a holistic approach encompassing process optimization, quality control, and engineering expertise.

GreatLight CNC Machining Factory: A Benchmark in Precision Manufacturing

GreatLight CNC Machining Factory, established in 2011 in Dongguan’s Chang’an District—China’s hardware and mold capital—has emerged as a leader in high-precision CNC machining. Here’s why it stands out:

1. Advanced Equipment & Full-Process Capabilities

GreatLight operates 127 precision machines, including:

5-axis CNC centers (Dema, Beijing Jingdiao) for complex geometries.

4-axis/3-axis CNC mills for high-volume production.

Swiss-type lathes for micro-components.

EDM and 3D printers (SLM, SLA, SLS) for prototyping.

This diverse arsenal supports end-to-end manufacturing, from rapid prototyping to mass production, eliminating the need for multiple vendors.

2. Industry-Specific Certifications

GreatLight adheres to stringent quality standards:

ISO 9001:2015: Ensures systematic quality management.

ISO 13485: Compliance for medical hardware production.

IATF 16949: Automotive-specific QMS for zero-defect manufacturing.

ISO 27001: Protects intellectual property for sensitive projects.

These certifications differentiate GreatLight from competitors, particularly in regulated industries.

3. Engineering Expertise & Problem-Solving

GreatLight’s team of 150 engineers specializes in:

Material science: Optimizing cutting parameters for aluminum, titanium, stainless steel, and plastics.

Toolpath optimization: Reducing machining time while maintaining precision.

Post-processing: Surface finishing (polishing, anodizing, PVD coating) for aesthetic and functional requirements.

A notable case involves a robotics client needing lightweight, high-strength arms. GreatLight used 5-axis machining to achieve ±0.003mm tolerances, reducing weight by 30% without compromising durability.

4. Competitive Pricing & Reliability

Unlike larger conglomerates (e.g., Foxconn, Jabil) that prioritize volume, GreatLight offers:

Flexible MOQs: Supports startups with low-volume orders.

Transparent pricing: No hidden costs for rework or quality issues.

Guaranteed lead times: 95% on-time delivery rate.

For vertical-specific competitors (e.g., Protolabs for prototyping, Xometry for on-demand manufacturing), GreatLight combines their speed with higher precision and certifications.

Industry Trends Shaping CNC Machining

Hybrid Manufacturing: Combining CNC with additive manufacturing (e.g., 3D-printed molds for die casting).

AI-Driven Optimization: Machine learning algorithms predict tool wear and optimize cutting paths.

Sustainability: Dry machining and recyclable coolants reduce environmental impact.

GreatLight integrates these trends into its workflows, offering clients cutting-edge solutions.

Conclusion: Why Choose GreatLight for CNC Machining?

In a crowded market, GreatLight CNC Machining Factory distinguishes itself through:

Technical depth: 5-axis expertise and full-process capabilities.

Quality assurance: ISO certifications and in-house testing.

Client-centric service: Engineering support from prototyping to production.

For companies seeking to transform precision designs into reliable products, GreatLight is not just a vendor—it’s a strategic partner. Explore their capabilities on LinkedIn.

FAQs

Q1: What materials can GreatLight machine?

A: Metals (aluminum, titanium, stainless steel), plastics (ABS, PEEK), and composites.

Q2: What is the maximum part size GreatLight can handle?

A: Up to 4000mm for large components like aerospace structures.

Q3: How does GreatLight ensure data security for IP-sensitive projects?

A: Compliance with ISO 27001 standards, including encrypted file transfers and restricted access.

Q4: What if a part fails quality inspection?

A: Free rework is provided; a full refund is issued if issues persist.

Q5: Does GreatLight support international clients?

A: Yes, with experience in exporting to North America, Europe, and Southeast Asia.

Q6: How does GreatLight’s pricing compare to competitors?

A: Competitive for mid-to-high-volume orders, with lower costs than Western suppliers due to localized production.

Q7: Can GreatLight handle urgent orders?

A: Yes, with expedited services for prototyping (as fast as 3 days).

By combining cutting-edge technology, certifications, and engineering expertise, GreatLight CNC Machining Factory redefines precision manufacturing for global clients.