Revolutionizing Machining Technology: The Unsurpassed Excellence of WFL

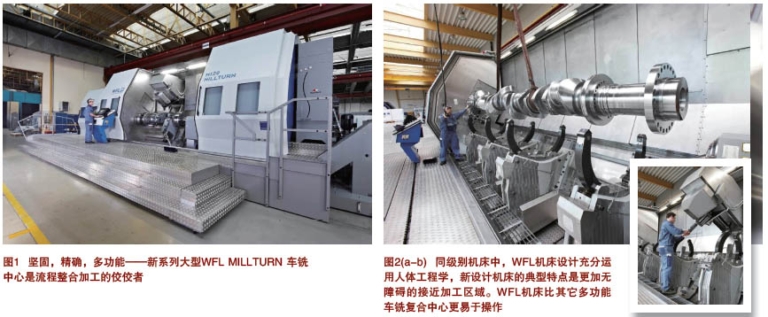

In the realm of machine tools, WFL Molding Technology has consistently demonstrated its unmatched prowess worldwide, showcasing its commitment to innovation and exceptional performance. This article delves into the cutting-edge features and capabilities of their turn and milling centers, which have garnered recognition as the largest professional manufacturer in the world, serving the aerospace and petroleum industries.

Unparalleled Capabilities: Maximizing Productivity and Flexibility

The M100, M120, and M150 models of WFL’s turn and milling centers boast impressive specifications, with a maximum length of 8000 mm (260.0 inches) and a spindle rotation diameter of up to 1560 mm (61.4 inches). The robust spindle power, reaching 126 kW (169.6 hp), and maximum torque of 12,400 Nm (9213.4 lbf-ft), ensure exceptionally high productivity.

The innovative grinding pin with a 55 kW (72.4 hp) gear provides unparalleled power even for low supply forces, making it an ideal choice for large-sized and heavy-duty drilling. The Super-Rigid Stay tail provides a tightening force of up to 15,000 Nm, allowing for the processing of ultra-long or large diameter bars with an aspect ratio up to 1:14.

Revolutionizing Tool Changing and Magazine Loading

The optional independent entry tool magazine can accommodate heavy-duty tools with a diameter of up to 1700 mm (66.9 inches) and a weight of up to 200 kg (441.0 lbs). The external heavy-duty tool changer, situated at the top of the tool magazine, can load tools up to 2500 mm (98.4 inches) long. Additionally, WFL’s robust bore bar slide allows for the processing of ultra-proximity holes and super heavy internal diameters.

Breakthrough Tool Changer and Magazine Design

The standard tool changer magazine has undergone a radical transformation, with a maximum tool length of 900 mm (35.4 inches) and a fast-tool changing system that can load tools weighing up to 35 kg (77.2 lbs). The new automatic tool changer boasts a tool change rate of 100 m/min (328.1 ft/min), driven by a rack and pinion system. The enclosure ensures a dust-free workspace behind the machining area, allowing for smooth and efficient operation.

A New Era in Machining Technology

As the pioneer of filming and milling technology, WFL’s innovative approach has revolutionized the industry. Their machines are designed to provide unparalleled process reliability, maximum maneuverability, and supreme performance. With an unwavering commitment to excellence, WFL’s products have transformed the way we approach machining, ensuring optimal results and client satisfaction.

Revolutionizing the Future of Machining

As we gear up for an era of rapid change and innovation, WFL’s cutting-edge technology is poised to lead the way. With their comprehensive range of turn and milling centers, WFL is redefining the boundaries of what is possible in machining. As the world’s largest professional manufacturer of machine tools for the aerospace and petroleum industries, WFL is poised to transform the future of manufacturing.

Join the revolution by discovering the limitless possibilities with WFL. Learn how their unparalleled technology can help you unlock new levels of productivity and precision. Expect a world of possibilities with WFL, where the boundaries of innovation know no limits.

Stay tuned for more updates on the latest advancements in machining technology, and discover how WFL is shaping the future of manufacturing.