01

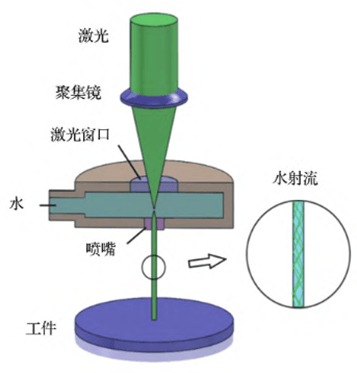

Principle of water conduction laser treatment

According to pulse width, laser heat sources are generally divided into continuous laser, long pulse laser, short pulse laser and ultra short pulse laser. Continuous laser and long pulse laser have higher processing speed, but will produce larger heat affected zone and easily form recast layer. In contrast, ultrashort pulse lasers can directly convert materials into a plasma state to achieve material eruption removal, thereby achieving a “cold processing” effect, but their processing efficiency is low. Compared to ultra-short pulse lasers, nanosecond-level short pulse lasers have lower acquisition costs and higher material removal rates. However, nanosecond pulse laser processing generates a large amount of heat, so it is still essentially a heat treatment process. It has typical thermal defects similar to long and continuous pulse laser processing, and it is easy to form a recast layer in the workpiece.

As the manufacturing industry’s demand for high-precision, high-efficiency processing technologies continues to grow, water-guided lasers have emerged to solve thermal problems encountered in traditional laser processing. In water conduction laser processing, the laser energy does not act directly on the surface of the workpiece like “dry laser”, but is transmitted to the workpiece by the water flow. The water flow here can be thought of as a glass fiber, and the laser is transmitted precisely and efficiently to the designated area in the water flow in a manner similar to optical fiber transmission. Once the stable water jet contacts the workpiece surface, the laser energy guided by the water jet will be absorbed by the material surface, causing the material in the area to melt and evaporate. ablation. During this process, the impact force of the water jet is much weaker than that of traditional water jet treatment. The main function of the water jet is to drive the laser, remove the waste produced by processing, and maintain the water jet surface. room at a lower temperature to protect its structure from damage. The stable water jet can couple lasers with different wavelengths and pulse widths without exceeding the breakdown threshold of water, and act on the workpiece surfaces of various materials within a suitable working distance, meeting thus meeting a wide range of production needs.

Figure 1. Principle of water-guided laser treatment.

Interaction between the laser and the water interface:

When the laser enters water from air, it undergoes processes such as refraction, scattering and reflection. The refractive index of water helps control the laser at the interface, helping to reduce laser beam divergence. that energy can be transferred to the room in a concentrated manner. At the same time, this feature of the interaction between water and laser makes it possible to avoid excessive attenuation of energy when the laser is transmitted through air.

Laser mode control in water flow:

As the laser propagates through the water jet, the shape, speed and thickness of the water flow will affect the mode of the laser beam. By controlling the flow rate and shape of the water flow, the laser pattern can be adjusted, thereby affecting the focus and distribution of the laser. Precise control of laser modes can further optimize energy distribution across the workpiece to meet microstructure processing needs.

Optimization of the laser waveform by liquid medium:

In water-guided lasers, the aqueous medium has a certain self-healing ability and can quickly restore the transmission channel during the laser pulse interval. Especially for high-frequency pulse lasers, the self-healing characteristics of the water jet ensure the stable transmission of the laser beam while avoiding the loss of the high-frequency laser on the water flow shape.

02

Water-guided laser drilling

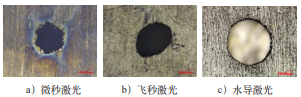

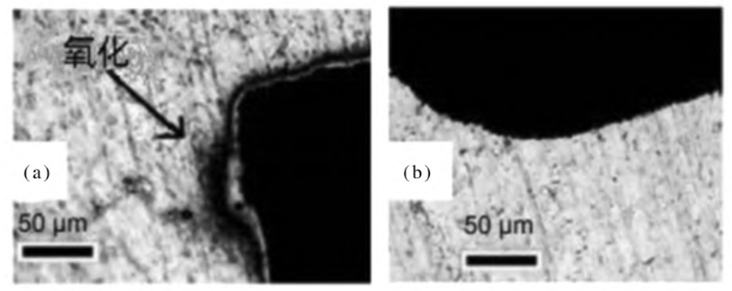

Traditional laser drilling has low precision and repeatability, and reflow and even microcracks will inevitably occur after processing. Therefore, foreign company SYNOVA cooperated with GE to develop processing technology that can be applied to the air film holes of turbine blades. Figure 2 compares the effects of the two laser drilling technologies. It can be seen that the edges of holes obtained by traditional laser drilling technology are rougher than those obtained by water-guided laser. To obtain finer holes, further processing is necessary. . The edges of holes obtained by water-guided laser processing are smooth and burr-free, resulting in better processing quality and obvious technical advantages.

Figure 2. Comparison between traditional laser drilling and water-guided laser drilling. (a) Traditional laser drilling; (b) Water-guided laser drilling.

In order to more clearly establish the advantages of water-guided laser drilling. Wang et al. used a microsecond laser, a femtosecond laser and a water-guided laser respectively to drill holes in the DD6 alloy, and the comparison of the obtained hole surface morphology is shown in Figure 3. There is an affected area thermally large on the hole surface obtained by microsecond laser, the hole edge continuity is poor and there is obvious deposition of molten material. This is because the pulse width and power of the microsecond laser are large and the material cannot be completely cooled after the pulse is completed, and the heat continues to be transferred into the material, resulting in an affected area thermally on a large scale, and the ablation material cannot be effectively discharged in time, deposited on the surface of the material to form droplet-like molten deposits. The hole surface processed by the femtosecond laser has almost no processing damage such as heat affected zone, material melting and redeposition. This is because the pulse width time of the femtosecond laser is shorter than the heat transmission time between the arrays. femtosecond laser processing This is a rough “cold working” process, resulting in better quality holes. However, due to the Gaussian distribution of laser energy, the taper of femtosecond laser holes is difficult to control, and the roundness of processed holes is poor and the processing efficiency is low, so it is difficult to process large quantities of holes. In contrast, water-guided laser removes molten material during the processing process, overcoming the problem of molten metal spatter in traditional microsecond laser processing. At the same time, the water jet travels efficiently through the cooling treatment wall, which can. Significantly improves process efficiency. Surface quality and reduction of heat affected zone.

Figure 3. Hole surface morphology produced by different laser processing methods.

Inquiry for water-guided laser equipment: 13522079385

03

Water guide laser cutting

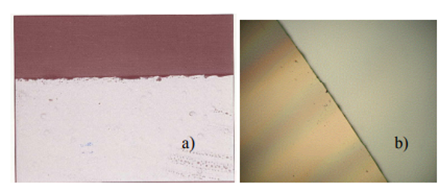

Laser cutting has many advantages in precision cutting of composites, ceramics and difficult-to-machine materials because there is no direct contact between the tool and the workpiece, resulting in no mechanical stress, friction and wear. However, the high thermal energy emitted by the laser can lead to problems such as loss of hardness and local collapse of the part surface. Therefore, many studies have proposed water-guided laser cutting technology. When processing hard, brittle or toxic semiconductor materials, we often encounter serious problems such as part drift and toxic aerosol pollution. The use of water-guided laser processing technology can not only effectively improve processing quality and production efficiency, but also avoid environmental pollution. Dushkina et al. compared the surface quality of gallium arsenide (GaAs) wafers cut by water-guided laser and traditional precision sawing processes, as shown in Figure 4. The cutting seams obtained by water-guided laser cutting are sharper, without burrs or debris, and the cutting speed is 7 to 10 times that of sawing. At the same time, the existence of a water jet prevents the diffusion of toxic gallium arsenide particles into the interior; the air.

Figure 4. Front surface quality comparison between precision sawing and water-guided laser cutting of gallium arsenide (GaAs) wafers.

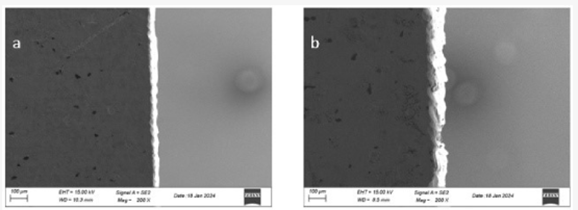

Paksoy et al. used traditional lasers and water-guided lasers to cut AISI1020 steel plates of different thicknesses. The study found that water-guided lasers significantly reduced the surface roughness of the material and minimized problems associated with traditional laser cutting, such as cutouts and cutouts. thermal damage. At the same time, compared with traditional laser cutting, the white layer produced by water-guided laser cutting is smaller, and the surface undulations are significantly improved.

Figure 5. SEM morphology of the surface after water-guided laser and traditional laser cutting. (a) Water-guided laser cutting; (b) Traditional laser cutting.

Similarly, Wagner et al. compared the effects of waterjet laser cutting with traditional laser cutting and found that under the conditions of constant cutting speed, materials processed by waterjet laser cutting had more advantages in terms of surface and interior roughness. heat affected zone of the structure evident.

Figure 6. Comparison of laser cutting and water-guided laser cutting of stainless steel. (a) Traditional laser cutting; (b) Water-guided laser cutting.

Analysis of surface morphological characteristics of water guide laser cutting:

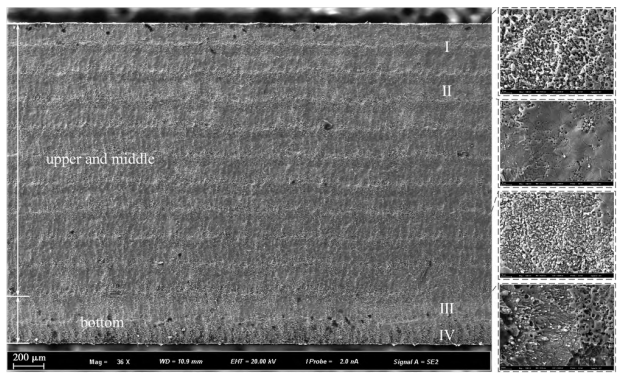

Guo et al. conducted a detailed analysis of the surface morphology of TC4 titanium alloy after water laser cutting. The bulges and depressions of the cut surface have different characteristics and are divided into 4 types of zones according to their morphological characteristics: bulge zone, depression zone, gravel zone and corrugated zone. Raised areas and depressed areas appear alternately in the upper and middle parts of the cutting surface, and gravel areas and wavy areas appear at the bottom of the cutting surface, as shown in Figure 7.

Figure 7. The cut surface is divided into ridge areas, depression areas, gravel areas, and wavy areas from top to bottom.

04

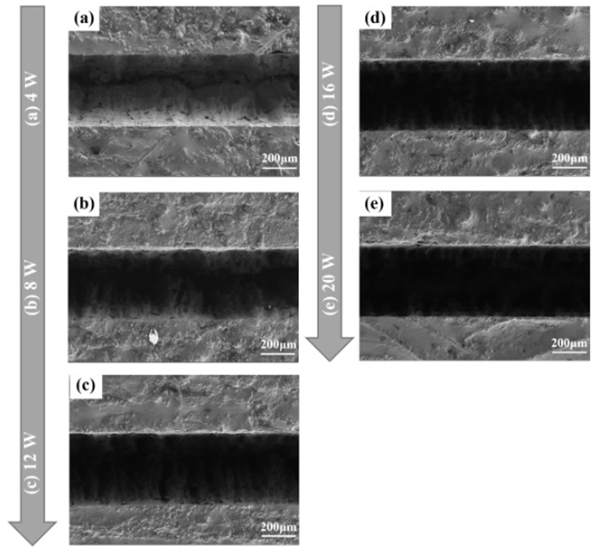

Water guide laser grooving

There is a huge defect in the processing of ceramic materials, that is, low toughness makes it easy for small cracks in ceramics to expand, thereby limiting the cutting processing of ceramics. Hu et al. studied water-guided laser grooving of ceramic materials under different process parameters. The study found that increasing laser power resulted in an increase in the width of the fusion zone on the surface of the surface material in micron increments. As the scanning speed increases, the ablation depth of the material is reduced but the ablation efficiency is increased. The overall experimental results show that the surface morphology of water-guided laser grooved ceramic materials is relatively good.

Figure 8. SEM images of water-guided laser grooving of ceramic materials at different laser powers.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.