Recently, Mohou.com learned that the US Army and the University of Arkansas (U of A) signed a contract worth $3.5 million to develop architectural 3D printing technology for disaster relief, also known as additive construction (AC) technology. Associate Professor Michelle Barry and Assistant Professor Cameron Murray of the Department of Civil Engineering at the University of Arkansas will conduct this research with Associate Professor Wenchao Zhou of the Department of Mechanical Engineering, whose startup AMBOTS will participate in the software programming aspect of the project. .

In fact, the $3.5 million in affiliate funding is part of a larger $12 million grant from the U.S. Army Engineer Research and Development Center to Applied Research Associates (ARA). ARA, a New Mexico-based research and engineering company, conducted research on AC technology to explore the potential for disaster relief forces to 3D print horizontal construction projects (e.g. culverts , T-walls and Jersey barricades) using local materials on disaster sites. .feasibility.

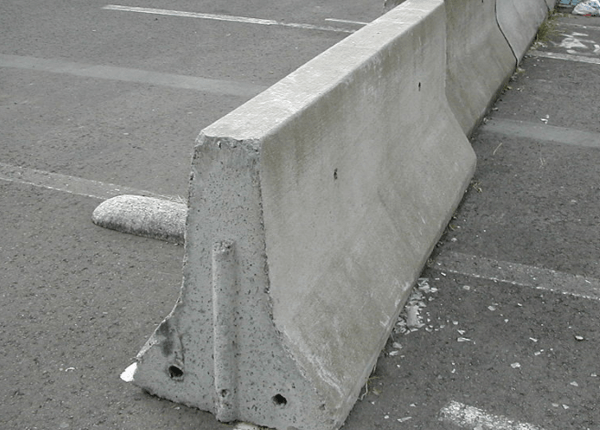

△Road blocks in Jersey

The University of Arkansas team will determine the best design models and local materials available for additive construction. Additionally, they will create code for mobile robots to deploy in the field to create these structures. Over the next two years, the team will develop architectural prototypes and the funding will be used to purchase a large-format 3D printer and other equipment for soil and concrete characterization.

use local materials

Barry of the University of Arkansas Granular Materials Research Laboratory will explore new material structures and geometric configurations to achieve optimal performance and efficiency. Proposed concepts include biomimetic structures, such as honeycomb patterns, designed to reduce material while optimizing strength.

△Murray participated in other real-world testing studies with the US Army. Image provided by University of Arkansas

Barry will also work with Murray, who specializes in concrete, to document and study the ability of various native soils to mix with concrete, analyze the resulting composition, and conduct large-scale testing on objects made from these materials. Rather than transporting cement and aggregates long distances, it is assumed that disaster relief forces are able to use concrete materials developed from local materials and robotic 3D printing technology, which can reduce costs, delays and environmental impact.

Barry said: “Humans have used soil for construction for thousands of years, but 3D soil printing allows us to use soil in new and exciting ways. We could build buildings or roads in disaster relief areas, where all that is needed is one piece of equipment. to bring, as you may not be able to import other building materials. If the local soil is useful, you print with them temporarily and people find shelter, and once they are no longer needed it returns to its original appearance. “.

Robot Swarm for architectural 3D printing

In addition to co-founding AMBOTS, which focuses on swarm robot manufacturing, Zhou is director of the Advanced Manufacturing, Modeling and Materials Laboratory at the University of Arizona. Zhou will be responsible for ensuring that the structure’s CAD files are properly translated into machine code for multiple machines to collaborate on 3D printing various materials. For this reason, AMBOTS will lead the software development of robots that will be designed to operate independently and collaborate with each other to adapt to different combinations.

△T-shaped wall transported to the KAF compound in Afghanistan. Image courtesy of the U.S. Army Corps of Engineers and Karla Marshall.

Zhou said: “We are excited about the opportunity to partner with ARA and leverage their industry knowledge and experience to develop cutting-edge 3D printing capabilities. This grant will allow us to invest in R&D and drive innovation in 3D printing technology for our community. , and unlock new possibilities for the future of construction and other industries.

The APA is an interesting partner in this project because it is already involved in infrastructure and national security. This includes “surface transportation research and development, pavement engineering and testing, pavement marking services, transportation asset management, traffic monitoring, geotechnical solutions, risk management, policy and planning, road safety, autonomy and innovative training solutions and technology deployment”. national security, the company said: “Our roots began in 1979 in military support, simulating and analyzing the effects of weapons and developing new weapon systems to improve the technological advantage of our forces, with modeling and simulation at the core. has become a company that develops protective facilities and improves the effectiveness of fighters.

△Trends in 3D printing and additive construction

3D printed culvert architectural structure

The University of Arkansas project also demonstrates that architectural 3D printing will become a dominant technology trend in the future. Mexican concrete giant CEMEX has developed a proprietary concrete recipe that uses local aggregates and cement for 3D printed structures, as demonstrated in COBOD’s recent AC project. WASP, on the other hand, focuses on using primarily native soils and clays to build its air-conditioned structures. Given the carbon footprint of the global cement industry and increasing resource scarcity in general, the shift to local, earth-based building materials is natural.

We are also seeing a decline in the use of collaborative robots for additive manufacturing. Although the number of companies using it publicly is small, one can only imagine that with the rapid increase in industrial robotic arms for material extrusion and wire-arc additive manufacturing, it does not make any doubt they will eventually be integrated into a single factory or collaborative environment. .

AMBOTS is one of the few companies so far demonstrating the use of collaborative robots for 3D printing in conjunction with broader manufacturing technologies. Another example is Divergent Technologies, whose manufacturing cell has not yet been publicly demonstrated, but it relies on industrial robotic arms to assemble complex parts that are 3D printed using the 3D printer 12-laser NXGXII metal from SLMSolutions. The project will provide AMBOTS with the opportunity to showcase its robotic technology on a large scale.

Architectural 3D printing for infrastructure resilience

As global warming causes more extreme weather events, the need to respond quickly to natural disaster situations will increase. In this case, one could imagine the U.S. Army Corps of Engineers deploying shipping containers full of industrial robotic weapons to disaster sites to repair coastal defenses damaged by hurricanes. The same technology could be used in conflict zones overseas to build bases on rugged terrain.

At this point, programs developed by AMBOTS can be ported to other robots that may be needed in the field, such as material transport or mobile patrol units. In fact, the startup can even build new robots on site if the engineering team needs them. After all, one of his previous projects saw a team of robots building a car and then driving it out of a mini-factory.

Additive construction promises to be an ideal technology for repairing or building resilient infrastructure at key points in the city. As noted by Matt Kremenetsky, macro analyst at 3DPrint.com, the Department of Defense is becoming the lead department for managing projects related to strengthening supply chains, an overarching concept that includes climate resilience .

Source: 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.