In the ever-evolving manufacturing world, precision engineering remains an important component in producing high-quality parts. As the industry advances, so does the technology that supports it. One notable innovation in this area is 5-axis CNC machining, a process that allows manufacturers to achieve unparalleled precision, efficiency and versatility. This comprehensive article delves into the intricacies of 5-axis CNC milling, exploring its benefits, applications, and the science behind its capabilities.

What is five-axis CNC machining?

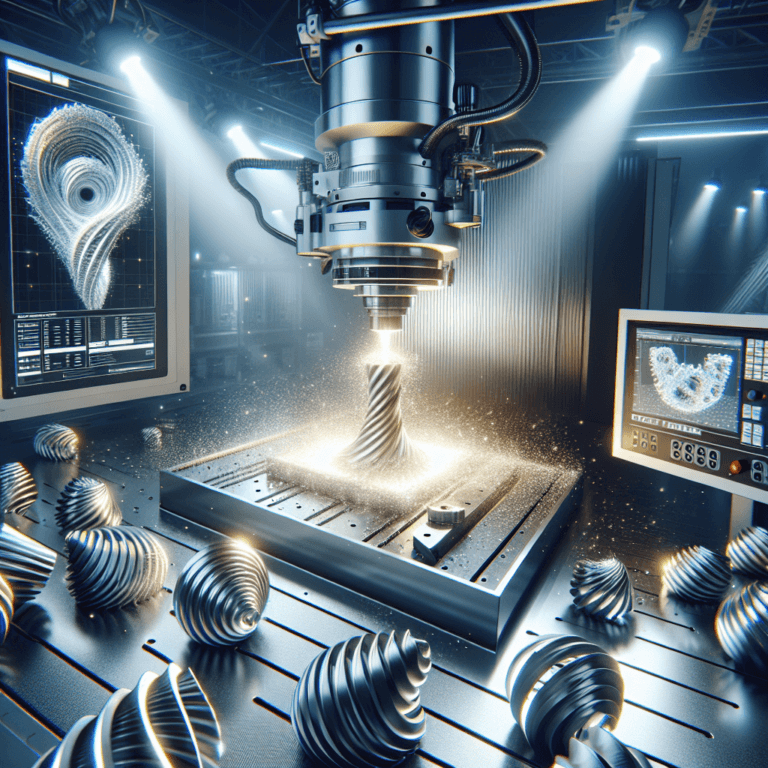

5-axis CNC machining refers to a type of computer numerical control (CNC) milling that operates on five different axes simultaneously. Unlike traditional 3-axis machining that only moves along the X, Y, and Z axes, 5-axis CNC machines can tilt and rotate the tool in multiple directions. This versatile functionality allows for the creation of complex geometries and detailed features in a single setup, reducing the need for re-fixing and manual handling.

Learn about axes of motion

The axes in 5-axis CNC machining can be roughly divided into main motion and auxiliary motion. The main movements involve the standard three linear axes (X, Y and Z). The auxiliary motion consists of two axes of rotation:

- A axis: Rotate around the X axis.

- B axis: Rotate around the Y axis.

This kinematic choreography makes it possible to perform milling, drilling and other subtractive techniques on all sides of the workpiece without having to reposition the workpiece in the machine. As a result, complex parts can be produced with high precision and excellent surface finish.

Advantages of five-axis CNC machining

1. Improve precision and accuracy

One of the most significant advantages of 5-axis CNC machining is the ability to achieve exceptional levels of accuracy. The machine’s ability to maintain tight tolerances, often within a few microns, ensures an unparalleled level of detail in the finished product. This kind of accuracy is critical across industries, especially aerospace, medical and automotive, where even the slightest deviation can have serious consequences.

2. Improve efficiency and save time

Traditionally, complex parts require multiple setups to machine, resulting in increased cycle times and the potential for errors. However, with 5-axis CNC machining, manufacturers can significantly reduce the number of setups, streamlining workflow and increasing productivity. The ability to perform complex machining operations in a single setup also minimizes downtime, ultimately saving time and cost.

3. Versatility of design and geometry

With its versatile motion capabilities, 5-axis CNC machining opens the door to innovative designs not possible with traditional methods. Complex features such as undercuts, complex contours, and polygonal contours can be easily machined, allowing for greater creativity and versatility in product design. This adaptability has led to wider applications across various industries.

4. Better surface finish quality

The continuous motion of the cutting tool during machining improves surface finish quality. The ability to maintain a constant cutting angle reduces the possibility of tool marks and defects, producing a smoother, more refined surface. The enhanced surface finish is particularly beneficial in areas where aesthetics or functionality are critical, such as medical implants or precision components.

5. Reduce human error

As with any technology driven by computer control, 5-axis CNC machining significantly reduces the possibility of human error. Because the machine performs complex movements based on programmed instructions, it minimizes the variability that comes with manual operation. This reliability increases overall production consistency and product quality.

6. Cost-effectiveness

While the initial investment in 5-axis CNC machining technology may be significant, the long-term benefits are undeniable. By optimizing setups, reducing cycle times and improving process efficiency, manufacturers can realize significant cost savings. Entities can produce high-quality components at competitive prices, ensuring profitability despite higher upfront costs.

Key Applications of 5-Axis CNC Machining

The innovative capabilities of 5-axis CNC machining transcend many fields and are suitable for a variety of applications. Here are some key areas where the technology excels:

aerospace industry

In the aerospace sector, the need for precision and weight reduction is paramount. 5-axis CNC machining helps create complex parts such as turbine blades, brackets and casings that must adhere to strict industry standards. The ability to produce lightweight, complex designs while maintaining tolerance levels ensures aerospace manufacturers can optimize performance and fuel efficiency.

Medical device manufacturing

The medical industry relies heavily on precision components for equipment ranging from surgical instruments to implants. CNC machining allows manufacturers to produce these products with the highest precision, ensuring their reliability and safety. Complex geometries commonly found in orthopedic implants can be easily achieved, resulting in improved patient outcomes and increased surgical compatibility.

Automotive Engineering

From specialized engine parts to unique body panels, the automotive industry benefits greatly from 5-axis CNC machining capabilities. The technology supports rapid prototyping and promotes design innovation, allowing manufacturers to produce high-performance components that meet the changing needs of the market.

Military and Defense

5-axis CNC machining is used in the military and defense sectors to produce complex parts that require precision and durability. Components such as missile guidance systems, weapons components and various hardware can be manufactured appropriately for reliable performance.

Tool and mold making

The manufacture of molds and tooling requires precision and versatility. 5-axis CNC technology can create complex mold designs, providing optimal performance in volume production scenarios.

The science behind 5-axis CNC machining

How a 5-axis CNC machine works

At the heart of 5-axis CNC machining lies the complex interplay between hardware and software. The machine’s components, including the spindle, attachments and CNC controller, work together to perform the required cuts and movements. The CNC controller interprets G-code—a coding language that tells the machine how to move.

Components of a five-axis CNC machine tool

Workbench: The platform for fixing the work piece. It may also include integrated indexing functionality that allows rotation and tilt movements.

Turntable: These devices provide the machine with an additional axis of rotation, enhancing its functionality.

Spindle: The electric component responsible for rotating the tool. Spindle speed and power are critical to achieving optimal cutting performance.

Cutting tools: Specialized tools designed to handle a variety of materials and perform different machining operations. Tool versatility affects machining options and results.

- CNC control software: Essential for programming and management operations. Modern CNC software allows for more complex and intuitive design input, and the machining process can be simulated for error checking before actual production begins.

The role of CAM software

Computer-aided manufacturing (CAM) software is playing a transformative role in improving the efficiency of 5-axis CNC machining. The software enables designers to model complex parts and convert them into tool paths that CNC machines can understand. Advanced CAM systems provide simulation capabilities that allow manufacturers to visualize machining processes before execution, thereby minimizing the risk of costly errors.

Cutting force and tool path optimization

As complexity increases, careful analysis of cutting forces is required. Understanding cutting forces is critical to selecting the right tool and optimizing tool paths to minimize wear and maximize efficiency. Various factors such as tool speed, feed rate and depth of cut must be considered in programming to ensure optimal performance and extend tool life.

Tool Precautions

Choosing the right tool is critical to successful 5-axis machining. Factors such as material compatibility, tool geometry and coatings play a vital role in the machining process. The right tool improves performance, minimizes tool wear and ensures improved surface finish quality.

The Challenge of 5-Axis CNC Machining

While the benefits of 5-axis CNC machining are significant, organizations must also address certain challenges associated with the technology.

High initial investment

Investing in a 5-axis CNC machine typically incurs a higher initial cost compared to a traditional 3-axis machine. This fee includes the purchase price of the machine, tools, software licenses, and installation costs. Manufacturers must evaluate their production needs and expected return on investment before adopting this technology.

Programming Complexity

The advanced capabilities of 5-axis CNC machines bring a level of programming complexity that may create barriers to entry. Skilled personnel are required to write the necessary G-code and operate the machine efficiently. Organizations may need to invest in training or hire experienced mechanics, further increasing costs.

Maintenance requirements

Maintaining 5-axis CNC machines requires attention to detail and preventive service to avoid costly downtime. Keeping spindles, tool holders and other critical components in optimal working order is critical to maintaining machine performance and service life.

in conclusion

5-axis CNC machining represents a major leap in manufacturing technology, providing superior precision, efficiency and versatility to different industries. Its ability to produce complex geometries with excellent surface finishes makes it a valuable tool in modern engineering. Despite challenges such as initial cost and programming complexity, the long-term benefits of adopting 5-axis CNC machining always outweigh these obstacles. As demand for high-quality parts continues to increase across industries, the adoption of this innovative technology is critical for manufacturers in their pursuit of operational excellence.

FAQ section

1. What materials can be processed by a 5-axis CNC machine?

5-axis CNC machines can effectively machine a variety of materials, including metals (aluminum, steel, titanium), plastics, composites and wood. Material selection depends on the specific application and the desired physical properties of the finished part.

2. How does 5-axis CNC machining compare to 3-axis machining?

5-axis CNC machining offers greater flexibility and the ability to create complex geometries with precision, while 3-axis machining is limited to linear motion along three axes. This allows 5-axis CNC machining to reduce setup and mold complexity, thereby increasing productivity.

3. Is it possible to retrofit an existing CNC machine to have 5-axis functionality?

While there is an option to retrofit existing CNC machines to 5-axis capabilities, this often requires significant investment in new components and control systems. Depending on the functionality required and expected throughput, it may be more economical to invest in a new 5-axis CNC machine.

4. Which industries benefit the most from 5-axis CNC machining?

The aerospace, medical, automotive, military, and tool and die manufacturing industries are the industries that benefit the most from 5-axis CNC machining because of their requirements for precision, complex parts and high-quality surface finishes.

5. How to ensure the quality of parts produced by five-axis CNC machining?

To ensure the quality of parts produced using 5-axis CNC machining, it is crucial to use high-quality molds, apply correct machining parameters, implement strict inspection processes, and continuously monitor the condition of the machine during production.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.