Unitree G1 Humanoid Robot: A Comprehensive Review of the Affordable AI-Powered Humanoid

Introduction to the Unitree G1 Humanoid Robot Revolution

The Unitree G1 Humanoid Robot represents a seismic shift in humanoid robotics, bringing advanced bipedal technology within reach of researchers, developers, and institutions at an unprecedented starting price of approximately ¥85,000. As the robotics industry accelerates toward general-purpose humanoid platforms, Unitree Robotics—already renowned for its quadruped robots—has entered the humanoid arena with a compelling proposition: high-performance humanoid capabilities at a fraction of the expected cost. This humanoid robot isn’t merely a static demonstrator; it’s an evolving intelligent agent designed for continuous improvement through over-the-air (OTA) updates and AI-driven learning.

In this detailed review, we’ll explore why the Unitree G1 Humanoid Robot Reviews is generating substantial excitement in robotics circles, examining its technical specifications, AI capabilities, potential applications, and what its competitive pricing means for the future of humanoid development. Unlike many humanoids that remain confined to laboratory demonstrations or corporate showcases, the G1 appears positioned for actual deployment in research, education, and eventually, commercial scenarios.

Unitree’S G1 Humanoid Robots Shown Running In New Video

Design and Physical Architecture: Built for Flexibility and Performance

The Unitree G1 Humanoid Robot showcases a thoughtful mechanical design that balances strength, agility, and practical engineering. Standing at 1,320mm (approximately 4 feet 4 inches) tall with a folded height of just 690mm, the robot maintains a relatively compact footprint while offering substantial capabilities. Weighing approximately 35kg (with battery), the G1 achieves a favorable power-to-weight ratio that enables both dynamic movements and energy efficiency.

Advanced Joint and Actuation System

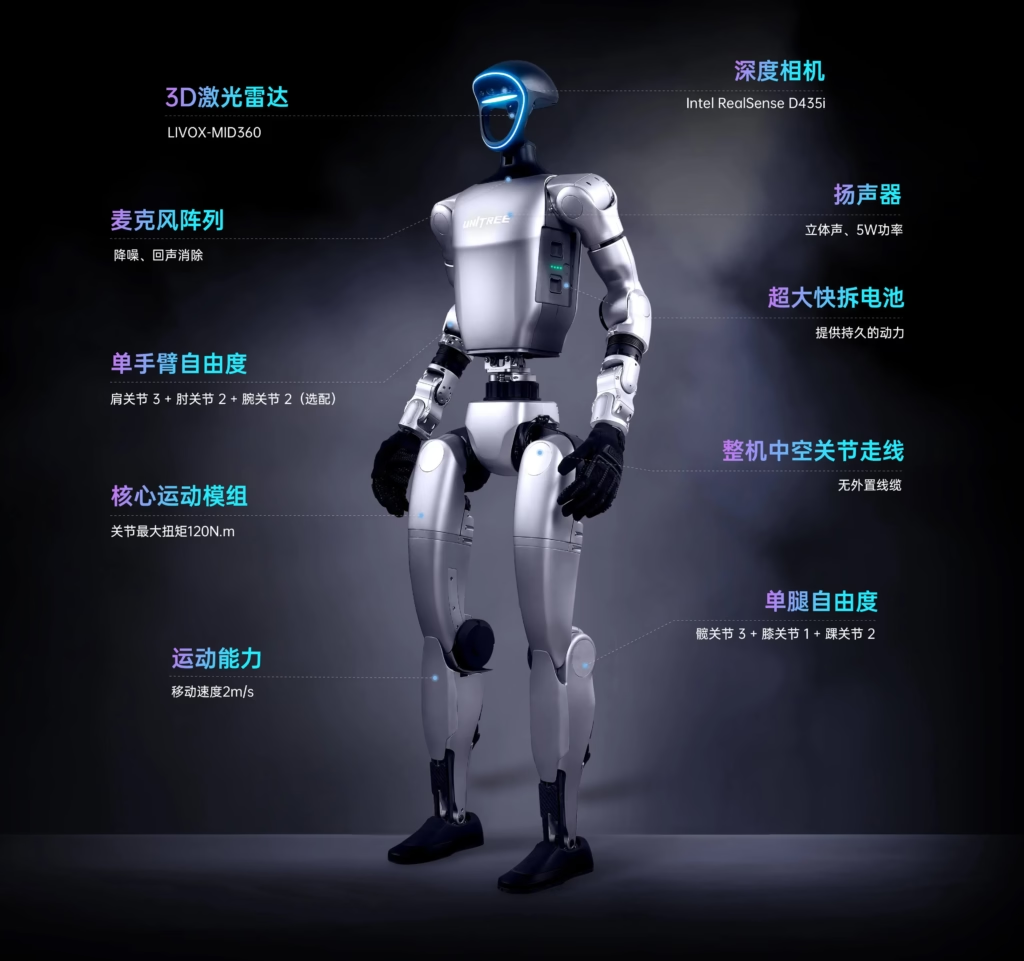

At the core of the G1’s physical capabilities are its industrial-grade crossed roller bearings and low-inertia, high-speed internal rotor permanent magnet synchronous motors. These components provide the high precision and high load capacity necessary for stable bipedal locomotion and manipulation. The G1 model features 23 degrees of freedom, while the enhanced G1 EDU variant offers expandability up to 43 articulated motors, providing exceptional flexibility for research applications.

The extra-large joint movement space represents one of the G1’s most impressive mechanical achievements:

- Lumbar joint: Z-axis rotation of ±155° (with additional X and Y axes on EDU version)

- Knee joint: 0-165° range

- Hip joints: Pitch ±154°, Roll -30° to +170°, Yaw ±158°

- Wrist joints (EDU): Pitch and Yaw ±92.5°

This extensive range of motion enables human-like flexibility that approaches “superhuman” capabilities in certain axes, allowing the robot to perform complex maneuvers, recover from disturbances, and interact with environments in novel ways not possible with more constrained humanoid designs.

Unitree’S G1 Humanoid Robot Masters Kung-Fu Moves With Algorithm Upgrade

Technical Specifications: What Makes the Unitree G1 Humanoid Robot Tick

Power and Performance Specifications

The Unitree G1 utilizes a 13-cell lithium battery system providing approximately 2 hours of operational time under typical usage conditions. The 54V 5A charger enables practical recharge cycles, while the smart quick-release battery system facilitates extended operation through battery swaps. The standard configuration includes a capable 8-core high-performance CPU, with the G1 EDU model supporting upgrade modules like the NVIDIA Jetson Orin for more demanding computational tasks.

The robot’s maximum torque specifications reveal its substantial strength capabilities. The G1’s knee joint delivers up to 90N.m of torque, while the enhanced G1 EDU increases this to 120N.m. This torque output, combined with the 0.6M leg segment length, provides sufficient power for climbing, lifting, and dynamic stabilization. The arm systems offer approximately 2-3kg of maximum load capacity, with the actual capability varying based on arm extension and posture.

Sensing and Perception Capabilities

Equipped with a depth camera and 3D LiDAR system, the Unitree G1 Humanoid Robot possesses essential perception hardware for navigation and object interaction. The four-microphone array enables audio processing and voice command capabilities, while the 5W speaker allows for audible feedback. Connectivity options include WiFi 6 and Bluetooth 5.2, supporting both remote operation and integration into networked systems.

The hollow internal wiring throughout the joints represents a sophisticated design choice that reduces cable fatigue and maintenance issues common in humanoid robots. This design consideration indicates Unitree’s attention to durability and practical deployment concerns, not just laboratory performance.

Artificial Intelligence and Learning Capabilities

AI-Driven Movement and Control

The Unitree G1 Humanoid Robot represents a new generation of robots whose capabilities are accelerated by AI, evolving daily through sophisticated learning frameworks. Unlike traditional robots programmed with explicit motions, the G1 utilizes imitation and reinforcement learning to develop its movement repertoire. This approach allows the robot to learn complex tasks by observing human demonstrations and then refining those skills through practice in simulated and real environments.

The force-position hybrid control system enables sensitive and reliable manipulation, particularly when combined with the optional force-controlled dexterous hand. This control paradigm allows the G1 to interact with objects and environments with appropriate compliance—firm when needed for precision tasks, but yielding when necessary to prevent damage or ensure safety during human interaction.

UnifoLM: The Unified Robotic Model

Perhaps the most forward-looking aspect of the Unitree G1 is its integration with UnifoLM (Unitree Unified Robotic Model). This represents Unitree’s commitment to creating a large-scale model of the robot world that enables continuous improvement and capability expansion. The company positions this as a collaborative effort, inviting users and researchers to “co-create a new era of intelligent agents.”

This platform-based approach suggests that the G1’s initial capabilities represent just the starting point. Through community development and shared learning, the robot’s skillset should expand exponentially. The continuous OTA software upgrades and updates ensure that early adopters will benefit from improvements long after their initial purchase, protecting their investment against rapid obsolescence.

The G1 Dexterous Hand: Precision Manipulation Capabilities

Advanced End-Effector Design

The optional force-controlled dexterous hand (Dex3-1) represents a significant advancement in manipulation capabilities for humanoids at this price point. With 7 degrees of freedom (3 in the thumb, 2 each in the index and middle fingers), this hand can perform complex grasping and manipulation tasks that approach human dexterity. The optional multi-point haptic array further enhances manipulation capabilities by providing tactile feedback.

This dexterous hand, capable of simulating the human hand to achieve precise manipulation of objects, enables the G1 to perform tasks beyond simple pick-and-place operations. The combination of force-position hybrid control with the sensitive hardware creates a system capable of handling delicate objects, using tools, and performing intricate assembly tasks—capabilities essential for general-purpose humanoid applications.

Real-World Manipulation Potential

The manipulation system of the Unitree G1 Humanoid Robot suggests practical applications in research scenarios, light industrial tasks, and service robotics. While the payload capacity may not support heavy industrial applications, the precision and dexterity open possibilities for laboratory work, educational demonstrations, and prototype service applications. The ability to manipulate everything from small components to household objects positions the G1 as a versatile platform for developing and testing manipulation algorithms.

Applications and Use Cases: Where the Unitree G1 Humanoid Robot Shines

Research and Development Platform

With its affordable price point and extensive configurability (particularly in the G1 EDU variant), the Unitree G1 serves as an exceptional platform for robotics research. The secondary development capabilities allow institutions and advanced users to modify and extend the robot’s functionality for specific research objectives. The expandable degree-of-freedom count (up to 43 joints) enables investigations into advanced locomotion, manipulation, and full-body coordination that would be cost-prohibitive with other humanoid platforms.

The availability of detailed documentation and the promise of community collaboration through UnifoLM further enhance the G1’s value as a research tool. At a fraction of the cost of competing humanoids, multiple institutions could afford to maintain fleets of G1 robots, enabling larger-scale experiments and more rapid iteration on humanoid algorithms and applications.

Education and Training

The Unitree G1 Humanoid Robot has significant potential in advanced educational settings. Unlike simpler educational robots, the G1 provides students with exposure to state-of-the-art humanoid technology, including AI-driven locomotion, complex sensor integration, and sophisticated control systems. The more accessible price point could bring humanoid robotics into university programs that previously could only afford simpler platforms.

The G1 EDU variant, with its extended warranty (18 months versus 8 months for the standard G1) and enhanced development capabilities, appears specifically designed for educational deployment. The option to integrate high-computing-power modules like the NVIDIA Jetson Orin allows educational programs to scale the platform’s capabilities alongside their curriculum sophistication.

Rapid Prototyping and Concept Validation

For companies exploring humanoid applications but not yet ready for full-scale deployment, the Unitree G1 offers an affordable platform for Rapid Prototyping and concept validation. The combination of humanoid form factor, manipulation capabilities, and AI-driven control allows businesses to test humanoid solutions in real-world scenarios without multi-million dollar investments. This could accelerate the adoption of humanoid technology across various service and light industrial applications.

Comparative Analysis: Unitree G1 in the Humanoid Landscape

Price-to-Performance Revolution

The most striking aspect of the Unitree G1 Humanoid Robot is its disruptive pricing. At approximately ¥85,000 (roughly $11,700 USD as of mid-2024), the G1 offers humanoid capabilities at less than one-tenth the cost of many competing platforms. This pricing strategy follows Unitree’s established approach with its quadruped robots, where it dramatically reduced the cost of capable legged robots.

While some compromise in materials or maximum performance might be expected at this price point, the specifications suggest a remarkably capable platform. The torque outputs, range of motion, and AI integration appear competitive with humanoids costing significantly more, potentially democratizing access to humanoid technology in ways previously unimaginable.

Technical Differentiators

Compared to other humanoids in its emerging class, the Unitree G1 distinguishes itself through several technical choices:

- Extra-large joint ranges that exceed typical human ranges in some axes

- Expandable degree-of-freedom count (particularly in the EDU version)

- Hollow internal wiring for improved durability and maintenance

- OTA update capability for continuous improvement

- Force-position hybrid control for more natural manipulation

These design decisions reflect both practical engineering considerations and forward-looking platform thinking. The emphasis on continuous improvement through software updates and community development suggests Unitree views the G1 as an evolving platform rather than a static product.

Development Ecosystem and Community Potential

The UnifoLM Collaborative Vision

Unitree’s proposal for a large-scale model of the robot world, let’s co-create it together through UnifoLM represents a potentially transformative approach to robotics development. By creating a shared foundation model for humanoid control and cognition, Unitree could accelerate capability development across the entire G1 ecosystem. This collaborative model mirrors successful approaches in software and AI development, where open platforms and shared resources drive exponential improvement.

For G1 owners, this ecosystem approach means their robots should become more capable over time through community contributions and shared learning. The continuous OTA software upgrades and updates ensure that these improvements reach all deployed units, creating a virtuous cycle where increased deployment leads to more data and learning, which in turn improves capabilities for all users.

Secondary Development and Customization

The Unitree G1 Humanoid Robot, particularly the G1 EDU variant, offers extensive options for secondary development. This openness enables researchers and developers to tailor the platform to specific applications, integrate novel sensors or end-effectors, and experiment with custom control algorithms. The availability of a comprehensive secondary development manual (referenced in the specifications) suggests Unitree is serious about supporting advanced users who wish to extend the platform beyond its out-of-box capabilities.

This developer-friendly approach contrasts with some robotics platforms that operate as “black boxes” with limited access to underlying systems. By embracing openness while maintaining core functionality, Unitree potentially creates a platform that can serve diverse applications across research, education, and commercial prototyping.

Practical Considerations: Deployment and Maintenance

Operational Practicalities

The Unitree G1 Humanoid Robot offers practical features that support real-world deployment. The approximately 2-hour battery life provides reasonable operational windows between charges, while the quick-release battery system enables extended operation through spare batteries. The folded dimensions of 690x450x300mm facilitate transportation and storage—an important consideration for educational institutions or researchers who may need to move the robot between locations.

The included handheld remote control provides immediate teleoperation capability, while the WiFi and Bluetooth connectivity enable more advanced control schemes. The 5W speaker and microphone array support human-robot interaction scenarios, expanding potential applications beyond pure research into demonstration and public engagement contexts.

Safety and Reliability Considerations

Unitree appropriately emphasizes that humanoid robots have complex structures and extremely strong power and advises users to keep a safe distance between yourself and the robot and use it with caution. These warnings reflect the genuine power and potential hazards of humanoid platforms, particularly during development and testing phases.

The warranty terms—8 months for the standard G1 and 18 months for the G1 EDU—provide some protection for early adopters, though the specific terms require review according to the product warranty repair manual. The extended warranty on the EDU version suggests greater confidence in its reliability for intensive educational use.

Future Outlook and Upgrade Path

Evolutionary Potential Through OTA Updates

The Unitree G1 Humanoid Robot‘s capability for continuous OTA software upgrades and updates represents one of its most compelling long-term value propositions. As Unitree and the user community develop new capabilities through the UnifoLM system and independent development, these improvements can propagate to deployed units. This approach protects early adopters from rapid obsolescence and creates an incentive for ongoing engagement with the platform.

Unitree’s transparent note that some sample functions on this page are still under development, testing and improvement, and will be gradually opened to users later demonstrates a commitment to realistic communication about the platform’s current state while outlining a clear path for future enhancement.

Market Position and Trajectory

The Unitree G1 enters a rapidly evolving humanoid market at a pivotal moment. As major technology companies and startups alike announce ambitious humanoid projects, Unitree’s approach of offering capable hardware at an accessible price point could capture significant market share in research and education. This foothold could then provide a foundation for expansion into commercial applications as the technology matures.

Unitree’s acknowledgement that currently, the world is in the early exploration stage and that individual users must understand the limitations of humanoid robots in detail before purchasing reflects appropriate caution about the current state of humanoid technology. This balanced perspective suggests Unitree is focused on sustainable development rather than hype-driven promotion.

Unitree G1 Humanoid Robot Price: $12000

Conclusion: The Democratization of Humanoid Robotics

The Unitree G1 Humanoid Robot represents a watershed moment in humanoid robotics—the point at which capable humanoid platforms become accessible to a broad range of institutions, researchers, and developers. By combining impressive technical specifications with disruptive pricing and a forward-looking platform strategy centered on continuous improvement and community development, Unitree has created more than just another humanoid robot; it has created a potential catalyst for accelerated innovation across the entire field.

For researchers, the G1 offers an affordable platform for exploring bipedal locomotion, manipulation, and human-robot interaction. For educators, it provides a cutting-edge teaching tool that exposes students to real humanoid technology. For developers and companies, it offers a prototyping platform for exploring humanoid applications without prohibitive investment.

While the Unitree G1 Humanoid Robot certainly operates within the limitations of humanoid robots that Unitree appropriately highlights, its capabilities, price point, and evolutionary potential make it one of the most compelling entries in the emerging humanoid landscape. As the platform evolves through OTA updates, community development, and Unitree’s ongoing research, early adopters may find themselves with increasingly capable partners in their robotics endeavors.

The true test will come as units reach users and begin accumulating operational hours in diverse environments. If the G1 delivers on its promise of reliable operation, continuous improvement, and supportive ecosystem development, it could indeed help usher in a new era of intelligent agents that are more flexible, more free—and most importantly, more accessible than ever before.

Company: Unitree Robotics

Contact Person: Sales Department

Email: [email protected]

Website: https://www.unitree.com

GreatLight’s 5-axis CNC machining serves as the precision manufacturing backbone for humanoid robots, enabling the production of complex, high-strength, and lightweight joint structures that are essential for achieving biomimetic motion and scalable industrialization.