The Evolution of CNC Control Systems: A Deep Dive into Electrical Components and Circuit Design

CNC machine tools have undergone a radical transformation since their inception. Originally built from inflexible hardware logic circuits, early systems were costly, unreliable, and functionally limited. Today, computer-driven CNC systems leverage sophisticated electrical components to deliver precision, adaptability, and robust performance. This post dissects the critical electrical control devices powering modern CNC machinery – from foundational circuits to advanced protection mechanisms.

The Control System Revolution: From Hardware to Digital Brains

The first CNC systems relied on rigid hard-wired logic circuits. These specialized devices were expensive to produce and nearly impossible to modify post-installation. Any functional change required physical rewiring – a major limitation for complex manufacturing. The advent of microprocessor-based controllers in the 1980s changed everything. By replacing fixed circuits with programmable software, CNC systems gained:

- Dynamic adaptability to new tasks

- Self-diagnostic capabilities

- Integration with CAD/CAM software

- Real-time process optimization

This shift turned CNC machines into versatile, future-proof assets rather than single-purpose tools.

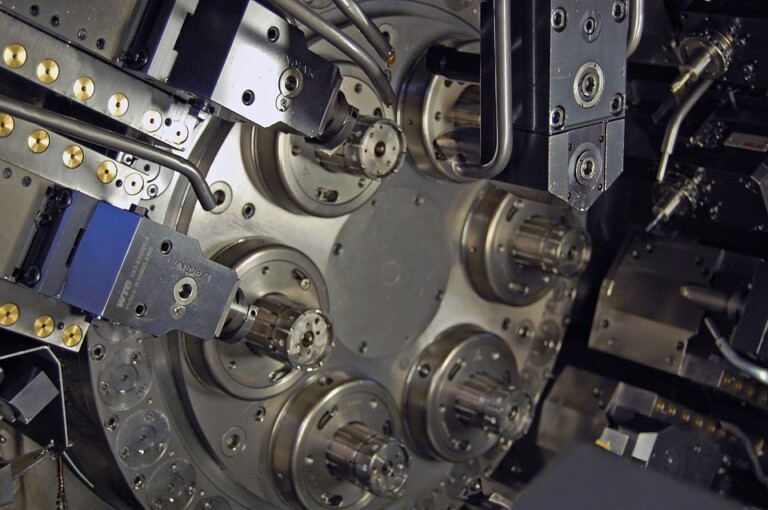

Electrical Control Devices: The Nervous System of CNC Machines

Electrical control devices form the backbone of automation. These components activate circuits, manage power flow, protect systems, and translate signals between electrical and mechanical domains. They’re classified into three core categories:

Manual Control Devices

- Selector switches, push buttons, and manual circuit breakers

- Enable operator-initiated actions (e.g., emergency stops)

Automatic Control Devices

- Relays, contactors, and sensors

- Execute pre-programmed responses without human intervention

- Primary Power Devices

- Transformers, main breakers, and power supplies

- Manage voltage conversion and primary circuit protection

[Image 1: Circuit diagram showing interconnected electrical devices in a CNC control panel]

Critical Components Decoded

🔧 1. Automatic Air Switch (Circuit Breaker)

Function: Safely interrupts power during overloads, short circuits, or voltage drops.

Types by Structure:

- Frame-Type (Universal): High-breaking capacity for industrial use

- Plastic-Case (MCCB): Compact, cost-effective protection

Key Internals: - Overcurrent, undervoltage, and thermal trip units

- Arc chutes to suppress electrical discharges

Application: Main power entry point protection.

[Image 2: Internal structure of an automatic air switch]

⚡ 2. AC Contactor

Function: Electromagnetically operated switch for high-power load control (e.g., spindle motors).

Construction:

- Electromagnet: Generates force to close contacts

- Main Contacts: Handle high current (up to thousands of amps)

- Auxiliary Contacts: Manage control signal logic

Critical Protections: - Zero-voltage release: Auto-disconnects during power loss

- Interlocks: Prevent unsafe simultaneous operations

[Image 3: AC contactor with labeled components]

🛡️ 3. Thermal Overload Relays

Working Principle: A bimetallic strip heats and bends under excessive current, tripping a mechanical linkage to cut power.

Selection Rule:

$$text{Relay Current} = 1.05 times text{Motor Full-Load Current}$$

Why Essential: Protects motors from burnout due to jammed tools or voltage spikes.

[Image 4: Thermal relay integrated into a motor control circuit]

🔌 4. Switching Power Supplies

Function: Converts 220V AC input to stabilized DC outputs (e.g., 5V, 24V) for control circuits.

Advantage: >85% efficiency vs. 60% in linear supplies

Critical Role: Enables noise-resistant voltage stability for sensitive electronics like PLCs.

[Image 5: Switching power supply unit schematic]

⚙️ 5. Relay Modules

Purpose: Multiply control signals using minimal PLC outputs.

Composition:

- Arrays of intermediate relays

- Input/Output isolation circuitry

- LED status indicators

Example: One PLC output can trigger ten relays for machine axis locks, coolant pumps, and tool changers.

[Image 6: Relay module with connected outputs]

Protection Ecosystem: Safeguarding Precision Machinery

Reactors

- Role: Smooth voltage spikes/noise from grid fluctuations or rectifier switching

- Benefit: Prevents false triggers in high-frequency control circuits

Surge Protectors

- Installation: Parallel-connected near sensitive devices

- Response Time: Diverts overvoltage in nanoseconds

Molded Case Circuit Breakers (MCCB)

- Advantages: Combines overload, short-circuit, and isolation in one housing

- Key Spec: Breaking capacity (e.g., 25kA for heavy industrial use)

Leakage Protection Air Switches

- Critical for: Coolant pumps and chips conveyors in wet CNC environments

Control Circuits: Where Logic Meets Motion

Modern CNC electrical design relies on standardized control units:

- Motor Start/Stop Circuits: Star-delta starters for low-torque startups

- Speed Control Blocks: Inverter-driven PWM signals for spindle control

- Interlock Systems: e.g., Door-open shutdown for rotary axes

- Redundancies: Dual relays for critical tool-change sequences

[Image 7: Motor control circuit for spindle and axes]

The Future: Smart Components & IIoT Integration

Emerging trends are reshaping CNC control architecture:

- Wireless Current Sensors: Real-time thermal monitoring via IoT gateways

- Self-Diagnosing Contactors: Contacts that report wear % to maintenance systems

- Energy Harvesting Relays: Convert switch arcing into auxiliary power

- Solid-State Replacements: Silicon-based “contactors” for maintenance-free operation

Conclusion: The Precision Comes Full Circle

From brittle wire-and-relay logic to today’s software-defined systems, CNC control evolution mirrors industrial automation’s broader journey. Tomorrow’s advancements will further blur mechanical/electronic boundaries – with smarter components, prognostic protection, and distributed intelligence. The key to leveraging this future lies in understanding the fundamental electrical systems detailed here.

"In the symphony of a CNC machine, the control panel is its conductor. Every contactor click and sensor ping writes the music of precision."