Understand RR CNC machining for accurate results

RR CNC machining is a popular technology used in modern manufacturing to produce high-precision parts with complex designs and complex geometries. In this blog post, we will dig into the world of RR CNC machining and explore its benefits, applications and best practices. By the end of this article, you will have a comprehensive understanding of RR CNC machining and how it can help you get accurate results in your manufacturing needs.

Basic knowledge of RR CNC machining

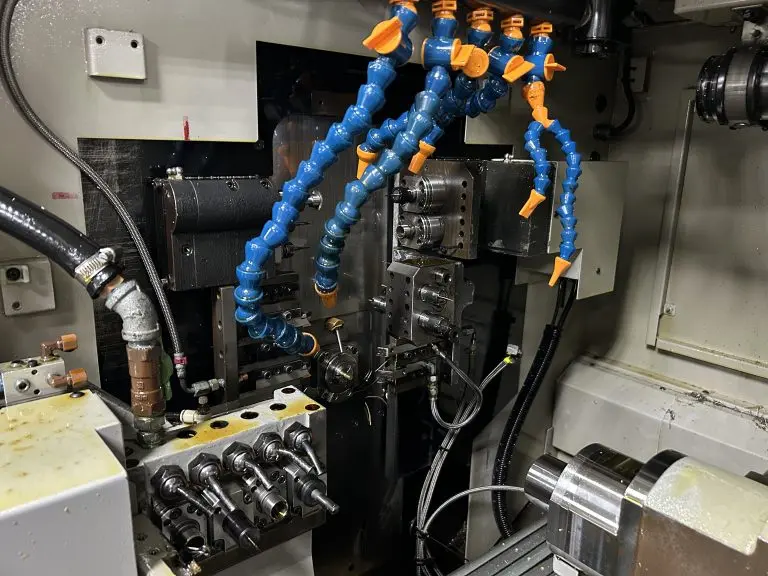

RR CNC machining is a computer numerical control (CNC) machining that uses rotating tools to remove materials from workpieces. the term "RR" represent "Rotate," This refers to the rotational movement of tools and workpieces. RR CNC machining is often used to produce parts with complex shapes, such as those found in the aerospace, automotive and medical industries.

Benefits of RR CNC machining

RR CNC machining offers some benefits that make it an attractive choice for manufacturers. Some key benefits include:

- Higher accuracy: RR CNC machining allows for higher accuracy and accuracy thanks to precise control of rotating tools and workpieces.

- Improve productivity: Due to the rapid and efficient removal of materials, RR CNC processing is more productive than traditional processing methods.

- Improved finish:RR CNC machining can produce high-quality surface finishes, which are essential for components that require smooth surfaces.

- Complex geometric functions:RR CNC machining can produce complex geometric parts using complex designs, while traditional machining methods are difficult to achieve.

Application of RR CNC machining

RR CNC processing is widely used in various industries. Some key applications include:

- aerospace:RR CNC machining complex components used to produce aircraft and spacecraft.

- car: RR CNC machining components used to produce vehicles such as engine blocks, cylinder heads and gearboxes.

- Medical:RR CNC processing is used to produce medical implants, surgical instruments and other medical devices.

- Consumer Products:RR CNC processing is used to produce consumer products such as watches, jewelry and precision instruments.

Best practices for RR CNC machining

In order to obtain precise results through RR CNC machining, best practices must be followed. Some key best practices include:

- Appropriate tool selection: Choosing tools suitable for work is crucial for RR CNC machining. The tool should be designed to handle the specific material and geometry of the workpiece.

- Precision worker: Accurate labor is crucial to ensure that the workpiece remains stable and accurate during processing.

- Optimization of processing parameters: Optimizing machining parameters such as spindle speed, feed rate and cutting depth is essential to obtain accurate results.

- Post-processing: Proper post-treatment techniques such as burrs and grinding are essential for achieving high-quality finishes.

in conclusion

RR CNC machining is a powerful technology that provides precise results and complex geometric functions. By understanding the basis, benefits, applications and best practices of RR CNC machining, manufacturers can produce high-quality parts with complex designs. Whether you want to produce aerospace components, automotive parts, medical implants or consumer products, RR CNC machining is an excellent choice for accurate results.

FAQ

Q: What is RR CNC machining?

A: RR CNC machining is a computer numerical control (CNC) machining that uses rotating tools to remove materials from workpieces.

Q: What are the benefits of RR CNC processing?

A: The benefits of RR CNC machining include higher accuracy, increased productivity, improved surface surface and complex geometric functions.

Q: Which industries use RR CNC processing?

A: RR CNC processing is used in industries such as aerospace, automotive, medical and consumer products.

Q: What are the best practices for RR CNC machining?

A: Best practices for RR CNC machining include appropriate tool selection, precise labor, optimization of processing parameters, and appropriate post-processing.

Q: Can RR CNC machining produce complex geometric parts?

A: Yes, RR CNC machining can produce complex geometric parts with complex designs.