The Future of Machining: Overcoming the Challenges of Creeping Cast Iron (CGI) with Advanced Metal Treatment Fluids

As the demand for cleaner, more efficient, and more powerful engines grows, the manufacturing industry is seeking innovative solutions to ensure the production of high-quality components. One material that has gained popularity in recent years is creeping cast iron (CGI), which has numerous benefits, including increased resistance, wear resistance, and thermal conductivity. However, its processing poses significant challenges, particularly when compared to traditional gray cast iron. In this blog post, we’ll delve into the challenges of machining CGI and explore how advanced metal treatment fluids can overcome these obstacles.

The Challenges of Machining CGI

Traditionally, metalworking fluids used for gray cast iron are not suitable for CGI. This is because the unique graphite structure in CGI, often referred to as "coral-like" or "worm-like," increases its hardness and wear resistance, making it more difficult to machine. Additionally, the lack of manganese sulfide (MNS) in CGI means it doesn’t have the same lubricity and protective properties as traditional gray iron, leading to higher tool wear rates.

The Difficulties of Machining CGI

Several factors contribute to the difficulties of machining CGI, including:

- Higher tool wear rates

- Longer processing times

- Compromised surface finish

- Higher costs due to increased tool replacement and extended processing times

The Impact of MNS on Machining Performance

The absence of MNS in CGI is a significant factor in its increased tool wear and decreased machining performance. MNS provides excellent lubricity and protection to tools, allowing for smoother cutting and reduced tool wear. In the absence of MNS, tools are more prone to wear and tear, leading to increased downtime and costs.

Recent Advancements in Metal Treatment Fluids

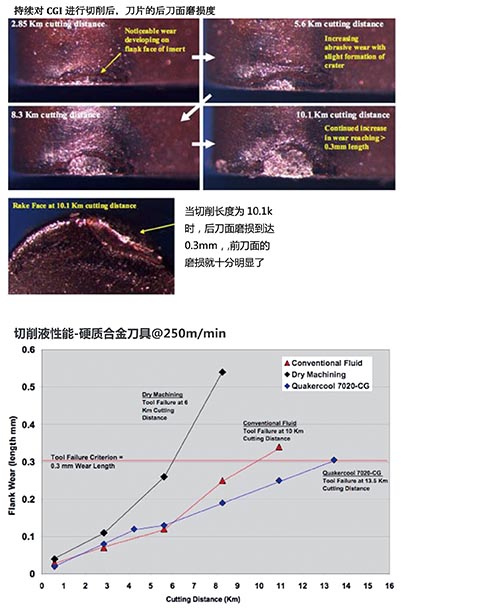

Recent tests have demonstrated the significant improvement in tool wear rates achieved through the use of advanced metal treatment fluids, specifically designed for CGI. Quaker Chemical’s Quakercool 7020 CG, for example, has shown remarkable results in reducing tool wear rates by up to 90% when machining CGI.

Innovative Solutions for the Future of Machining

The development of advanced metal treatment fluids, such as Quakercool 7020 CG, offers a potential solution to the challenges posed by CGI machining. These innovative solutions can improve tool lifespan, surface finish, and overall machining performance, reducing costs and increasing efficiency. By understanding the underlying causes of low CGI machining performance, manufacturers can develop more effective treatments that address the unique challenges of this versatile material.

Conclusion

The challenges of machining CGI are well-documented, but the benefits of this material make it an attractive option for engine manufacturers. By understanding the impact of MNS on machining performance and the opportunities provided by advanced metal treatment fluids, manufacturers can overcome the difficulties of CGI machining and unlock the full potential of this innovative material. Whether you’re a manufacturer, machining expert, or student, understanding the complexities of CGI machining is crucial for the future of the industry. Stay ahead of the curve by exploring the innovative solutions and advancements in metal treatment fluids, and discover how to overcome the challenges of machining CGI.