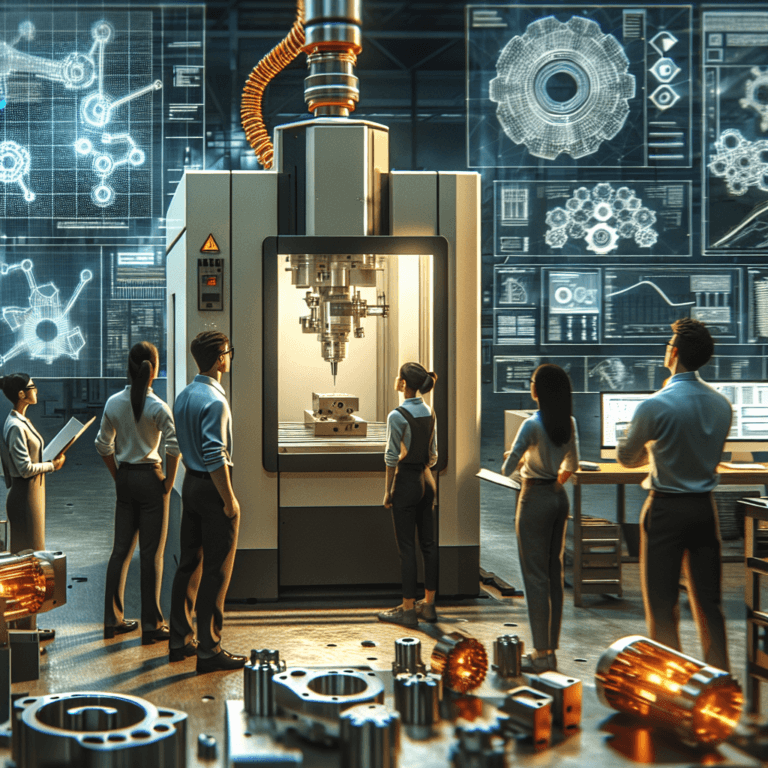

In the world of advanced manufacturing, CNC (computer numerical control) machining stands out as the paradigm for manufacturing precision parts with unparalleled precision and repeatability. The technology has revolutionized several industries including aerospace, automotive, medical devices and electronics due to its ability to produce complex parts that meet the highest quality and precision standards. In this comprehensive article, we explore the top CNC machining technologies used to manufacture precision parts, delving into their mechanisms, benefits, and applications.

Introduction to CNC machining

CNC machining is a subtractive manufacturing process that uses computer-controlled machinery to remove material from a workpiece and form it into the desired shape. This approach offers several advantages over traditional machining, including increased automation, improved accuracy, and the ability to efficiently produce complex geometries. CNC machining is critical for producing components used in high-risk industries where margins of error can have serious consequences.

Understand CNC machining accuracy

In CNC machining, accuracy refers to the accuracy of the parts produced relative to the design specifications. This precision is critical because components often need to fit together to tight tolerances. Factors that affect accuracy include machine calibration, tool selection, the quality of the materials used, and the machining process itself. The combination of these elements determines the overall accuracy and repeatability of a machined part, so choosing the right technology for a given application is critical.

Top CNC machining technology

The following CNC machining technologies are among the most efficient for producing precision parts. Each technology serves a specific purpose, providing various benefits depending on the requirements of the final product.

1. CNC milling

CNC milling is one of the most important CNC machining techniques and involves the use of rotating tools to remove material from a fixed workpiece. The technology is versatile and can produce complex shapes and geometries, making it ideal for precision parts across a variety of industries.

Advantages of CNC Milling

- Versatility: Able to handle a variety of materials, including metals, plastics and composites.

- complex geometric shapes: Ability to create complex parts such as slots, pockets and profiles.

- High precision: Provides tight tolerances and excellent surface finish.

- automation: Reduce reliance on manual intervention and improve repeatability.

CNC milling applications

- Aerospace components such as wing spars and turbine blades.

- Automotive parts such as engine blocks and transmission housings.

- Medical devices, including surgical instruments and implants.

2. CNC turning

CNC turning is a manufacturing process that involves using cutting tools to rotate a workpiece to form a cylindrical shape. The technology is particularly suitable for producing radially symmetrical parts and is often used for parts requiring high precision.

Advantages of CNC turning

- accuracy: Since the rotation speed and cutting depth can be controlled, high precision can be achieved, especially for round parts.

- efficiency: Quick material removal reduces cycle time.

- Easy to set up: Typically fewer tools are required compared to the milling of some parts.

Applications of CNC turning

- Shafts, axles and spindles in automotive and industrial applications.

- Medical applications such as orthopedic rods and connectors.

- Oil and gas industry components such as valves and fittings.

3. CNC grinding

CNC grinding is a precision machining process used to achieve fine tolerances and surface finishes. This technology uses a grinding wheel to remove material and is ideal for hard materials and parts that produce tight specifications.

Advantages of CNC grinding

- Fine tolerances: Surface finish can reach Ra 0.1 micron, suitable for high-precision applications.

- Material hardness: Ability to machine tougher materials, including hardened steel and ceramics.

- Minimal thermal deformation: Reduce the risk of thermal deformation due to low temperatures.

CNC grinding applications

- Tool production, such as drills and end mills.

- Precision gauges and molds.

- Aerospace and automotive components such as gears and bearings.

4. CNC electrical discharge machining (EDM)

CNC EDM is a process that uses electrical discharge or sparks to remove material from a workpiece. The technology is particularly effective for hard materials and complex geometries that are not easily achievable with traditional machining.

Advantages of CNC EDM

- complex shapes: Able to produce complex shapes with high precision.

- Material diversity: Effective for machining hard metals including titanium and tool steel.

- No mechanical stress: Avoid exerting physical force on the workpiece, minimize deformation and maintain dimensional accuracy.

Application of CNC EDM

- Injection molding and die casting molds.

- Manufacturing of aerospace components requiring complex geometries.

- Components for the semiconductor industry.

5. CNC laser processing

CNC laser processing is a non-contact technology that utilizes high-power lasers to cut or engrave materials. This technology is becoming increasingly popular for its ability to produce precise cuts without the mechanical limitations associated with other methods.

Advantages of CNC laser processing

- accuracy: Provides high-precision cutting with minimal kerf width, ideal for complex designs.

- Versatility: Works on a variety of materials including metals, plastics and textiles.

- speed: Processing time is fast, especially beneficial for large projects.

Application of CNC laser processing

- Sheet metal manufacturing used in the automotive and aerospace sectors.

- Custom signage and displays.

- Engraved components for electronic devices.

6. CNC water jet cutting

CNC waterjet cutting uses high-pressure water (sometimes mixed with abrasives) to cut a variety of materials. The technology is ideal for making precision cuts without introducing heat, which can cause material distortion or damage.

Advantages of CNC waterjet cutting

- no heat affected zone: Avoid thermal deformation, suitable for heat-sensitive materials.

- material independence: Works on a variety of materials including metal, glass and stone.

- Complex cutting: Ability to create complex designs and patterns.

Application of CNC water jet cutting

- Architectural features such as intricate facades.

- Custom parts for a variety of industries, including aerospace and automotive.

- Artistic applications in sculpture and design.

7. CNC additive manufacturing

Although traditionally classified separately, CNC additive manufacturing incorporates CNC principles into the 3D printing process. It involves layering materials to produce complex geometries, making it an innovative alternative for precision parts.

Advantages of CNC Additive Manufacturing

- complex geometric shapes: Ideal for producing parts that are difficult or impossible to machine in traditional ways.

- Reduce waste: Minimize waste by adding material rather than subtracting it.

- rapid prototyping: Supports rapid iteration of design and testing.

Applications of CNC Additive Manufacturing

- Prototyping for the aerospace and automotive industries.

- Medical implants are customized to specific patient needs.

- Production of electronic product parts with complex internal structures.

Factors affecting the success of CNC machining

While understanding the various CNC machining technologies is essential for producing precision parts, it is equally important to recognize the factors that influence their success.

1. Material selection

Material selection significantly affects the CNC machining process. Different materials react differently to cutting tools, speeds and feeds. The choice of materials such as aluminum, stainless steel, titanium or plastic should be based on the complexity of the required part, tolerances and cost considerations.

2. Molds and workholding fixtures

Effective tools are critical to achieving the accuracy required for CNC machining. The selection of suitable cutting tools and reliable workpiece clamping methods ensure the stability of the machining process. Rigidity is essential to prevent vibrations that can cause inaccuracies.

3. Software integration

Advanced software solutions can optimize CNC machining by providing simulation capabilities, allowing operators to visualize the machining process and identify potential problems before production begins. This proactive approach prevents costly mistakes and increases efficiency.

4. Processing parameters

Parameters such as feed rate, spindle speed and depth of cut are crucial for optimizing machining operations. Each material and technology has its ideal parameters to increase productivity while maintaining quality. Participating in a trial run or using technology-driven solutions can help fine-tune these parameters.

5. Quality control

Establishing strict quality control processes is an integral part of precision parts production. Implementing practices such as in-process inspections, statistical process control, and post-process evaluation ensures that each part meets specified standards.

in conclusion

CNC machining has cemented its place as the cornerstone of modern manufacturing, enabling industries to produce precision parts with unparalleled precision and efficiency. By understanding the various CNC technologies available, including CNC milling, turning, grinding, EDM, laser machining, waterjet cutting and additive manufacturing, manufacturers can choose the appropriate approach to meet their specific needs.

To succeed in this competitive environment, factors such as material selection, tooling, software integration, processing parameters and quality control must be considered. As technology continues to advance, the potential applications and enhancements of CNC machining are likely to expand, paving the way for greater innovation and precision in manufacturing.

FAQ section

Q1: What is the difference between CNC milling and CNC turning?

A1: CNC milling involves using a rotating tool to cut a fixed workpiece, allowing the creation of complex shapes and features. CNC turning involves rotating a workpiece while using cutting tools to remove material, typically for cylindrical parts.

Q2: What materials can be processed using CNC technology?

Answer 2: CNC machining can handle a variety of materials, including metals (such as aluminum, steel, and titanium), plastics, composites, and more. Material selection depends on the required mechanical properties and application.

Question 3: How do I determine which CNC machining technology is best for my project?

A3: To determine the best technique, consider factors such as the geometry of the part, the materials to be used, the tolerances required, throughput, and budget. Consulting with an experienced machinist or engineer can also provide valuable insight.

Q4: What role does automation play in CNC machining?

A4: Automation increases the efficiency and consistency of the CNC machining process. Automated systems can perform complex machining tasks, reduce manual intervention, reduce errors and increase production speed.

Q5: How does quality control affect CNC machining?

A5: Quality control is critical to ensure precision parts meet specified tolerances and functional requirements. Implementing strict quality control processes can reduce defects, minimize waste, and increase customer satisfaction.

By employing these top-notch CNC machining technologies and understanding the associated factors, manufacturers can efficiently produce high-quality precision parts to meet the demands of today’s dynamic market landscape.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.